11

Condensate Piping Connections

The air handler is provided with ¾” NPT condensate

drain connections.

Do not overtighten drain fitting.

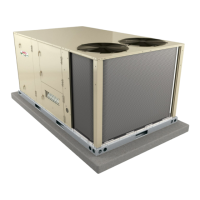

Unit must be slightly inclined toward drain connection.

Unit

To approved drain

Do not operate unit without condensate drain trap.

3”

3”

Clean Out

Do not glue

Anti-siphon vent must

extend above the height

of the coil drain pan by

2” (51 mm).

Figure 11. Condensate Drain Trap

1. Install properly sized, eld-provided connection

ttings and connect primary drain line to

the main drain pan connection (3/4” I.D.).

NOTE - When installing drain line connection ttings to the

drain pan, hand tighten the tting and use a thread sealant.

Over-tightening the ttings can split connections on the drain

pan.

2. If the secondary drain line is to be used, remove

the plug or the knockout and route the drain line

so that water draining from the outlet will be easily

noticed by the user. Refer to local codes for drain

trap requirements on the secondary drain line.

3. Check again to ensure drain ports and drain pan are

free of all debris.

4. Plug and check any unused drain pan openings for

tightness to prevent water leaks or seepage from the

drain pan.

5. Install a 3” trap in the main (primary) drain lines as

close to the unit as practical (see gure 11). Make

sure the top of the trap is below the connection to

the drain pan to allow complete drainage of the pan.

NOTE - Horizontal runs must have an anti-siphon air

vent (standpipe) installed ahead of the horizontal run.

See gure 11. An extremely long horizontal run may

require an oversized drain line to eliminate air traps.

NOTE - Do not operate air handler without a trap in

the main (primary) drain. The condensate drain is on

the negative pressure side of the blower; therefore,

air being pulled through the condensate line will not

allow positive drainage without a proper trap.

6. Route the drain line to the outside or to an

appropriate drain. Drain lines must be installed

so they do not block service access to the front

of the air handler. A 24” clearance is required for

lter, coil, or blower removal and service access.

NOTE - Check local codes before connecting the

drain line to an existing drainage system. Insulate

the drain lines where sweating could cause water

damage.

7. After the system installation is complete, the

condensate drain line must be checked for leaks

and proper drainage. If a eld-provided condensate

pump has been installed, it must be checked to

ensure proper operation. This check is part of the

commissioning sequence.

Using an External Water Level Switch

Disconnect the closed circuit loop, CN 5. Connect the

water level switch cable accessory to CN 5. See unit

wiring diagrams for location of CN 5.

The connection has 5 VDC current, do not supply eld

voltage.

IMPORTANT

Drain should have a slope of at least 1/4 inch per foot

and should be approved corrosion-resistant pipe. You

must conrm operation of every drain and pump in the

system as part of the commissioning procedure.

IMPORTANT

A eld-fabricated secondary drain pan, with a drain pipe

to the outside of the building, is required in all installa-

tions over a nished living space or any area that may

be damaged by overow from the main drain pan.

CAUTION

Make sure that drain piping is properly routed and

insulated in order to prevent both leaks and condensation.

Follow these instructions exactly to ensure proper

drainage and unit operation.

IMPORTANT

You must conrm operation of every drain and pump in

the system as part of the commissioning procedure.

Loading...

Loading...