XC14 - 1.5 to 5 Ton Air Conditioner / Page 4

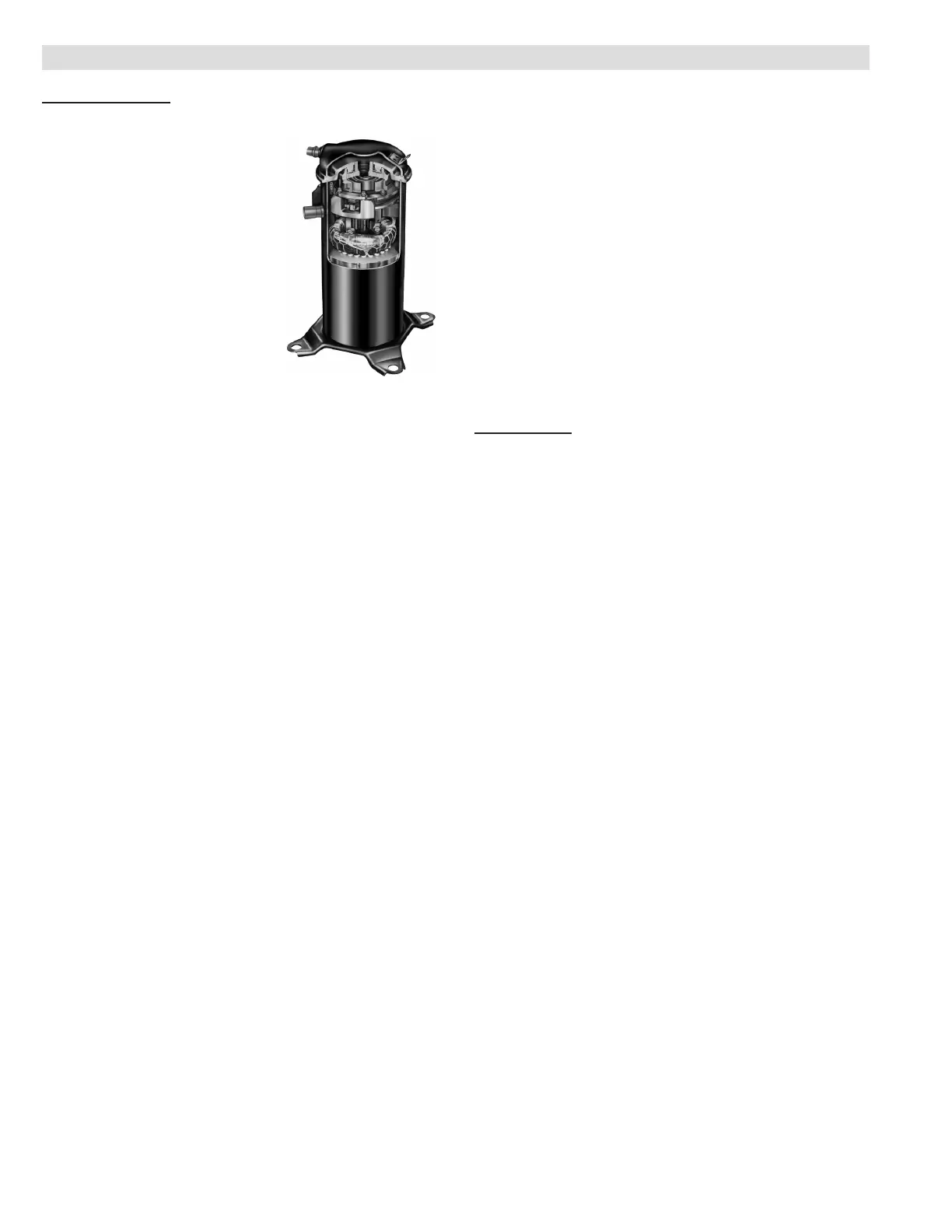

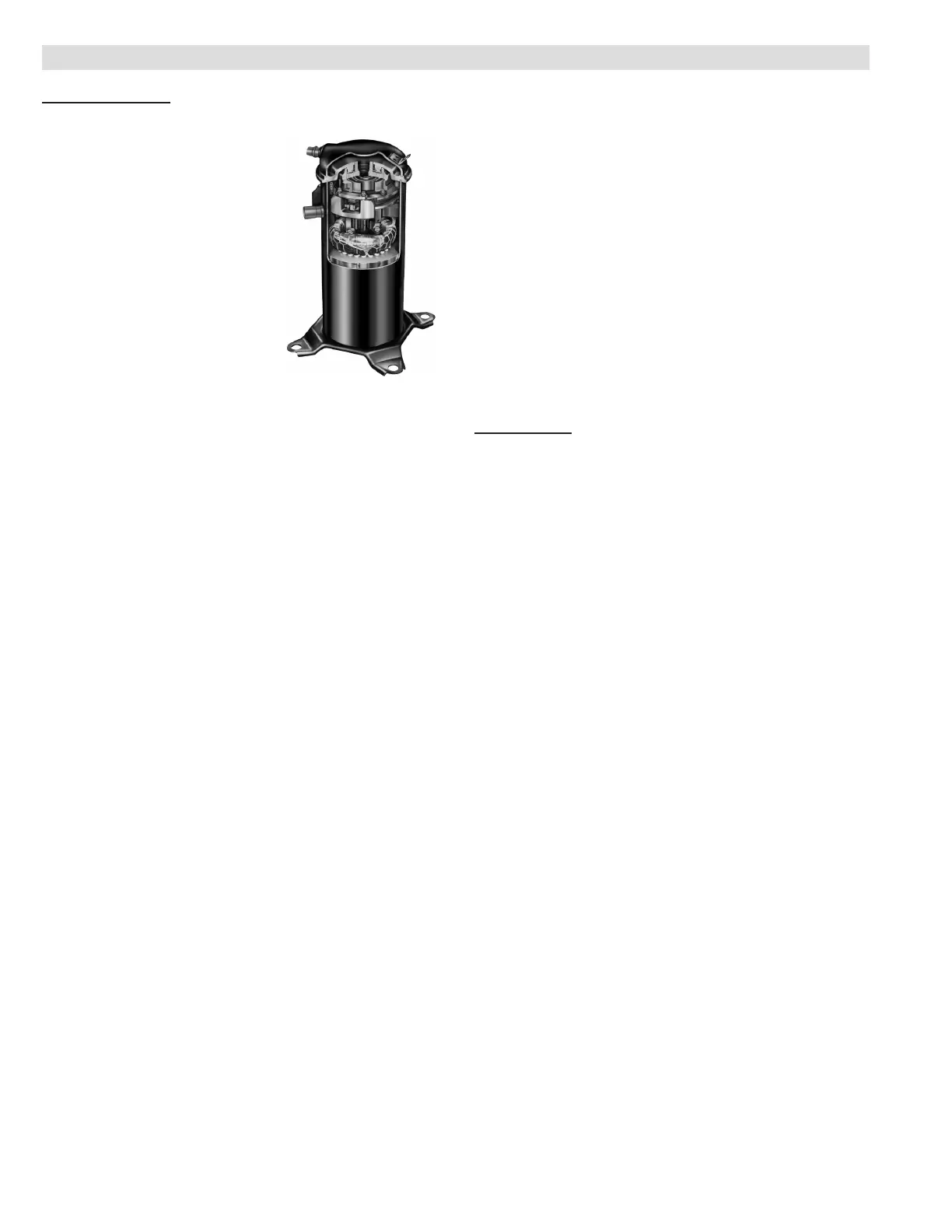

COMPRESSOR

Scroll Compressor

Compressor features high

efciency with uniform suction

ow, constant discharge ow and

high volumetric efciency and

quiet operation.

Compressor consists of two

involute spiral scrolls matched

together to generate a series of

crescent shaped gas pockets

between them.

During compression, one scroll

remains stationary while the other

scroll orbits around it.

Gas is drawn into the outer pocket, the pocket is sealed

as the scroll rotates.

As the spiral movement continues, gas pockets are

pushed to the center of the scrolls. Volume between the

pockets is simultaneously reduced.

When pocket reaches the center, gas is now at high

pressure and is forced out of a port located in the center

of the xed scrolls.

During compression, several pockets are compressed

simultaneously resulting in a smooth continuous

compression cycle.

Continuous ank contact, maintained by centrifugal

force, minimizes gas leakage and maximizes efciency.

Scroll compressor is tolerant to the effects of slugging

and contaminants. If this occurs, scrolls separate,

allowing liquid or contaminants to be worked toward the

center and discharged.

Low gas pulses during compression reduces

operational sound levels.

Compressor motor is internally protected from

excessive current and temperature.

Compressor is installed in the unit on specially

formulated, resilient rubber base for improved sound

dampening and vibration-free operation resulting in

quieter operating sound levels. See Outdoor Sound

Data table for details.

Compressor Crankcase Heater (048 & 060 Models)

Protects against refrigerant migration that can occur

during low ambient operation.

Factory Installed

Compressor Sound Dampening System

A polyethylene compressor cover containing a 2 inch

thick batt of berglass insulation for better sound

dampening.

All open edges are sealed with a one-inch wide hook

and loop fastening tape.

F

OPTIONS

Compressor Crankcase Heater (018 thru 042

models)

Protects against refrigerant migration that can occur

during low ambient operation.

Compressor Hard Start Kit

Single-phase units are equipped with a PSC

compressor motor. This type of motor normally doesn’t

need a potential relay and start capacitor.

In conditions such as low voltage, this kit may be

required to increase the compressor starting torque.

Compressor Low Ambient Cut-Off

Non-adjustable switch (low ambient cut-out) prevents

compressor operation when outdoor temperature is

below 35°F.

CONTROLS

OPTIONS

Indoor Blower Off Delay Relay

Delays the indoor blower-off time during the cooling

cycle.

See AHRI System Matches for usage.

Low Ambient Kit

Air conditioners operate satisfactorily down to 45°F

outdoor air temperature without any additional controls.

Low Ambient Control Kit can be eld installed, allowing

unit operation down to 30°F.

Freezestat should be installed on compressors

equipped with a low ambient kit.

A compressor lock-out thermostat should be added to

terminate compressor operation below recommended

operation conditions

Thermostat

Thermostat not furnished with unit. See Thermostat

bulletins in Controls Section and Lennox Price Book.

Compressor Timed-Off Control

Kit prevents compressor short-cycling and allows time

for suction and discharge pressure to equalize.

Permits compressor start-up in an unloaded condition.

Automatic reset with 5 minute delay between

compressor shut-off and start-up.

FEATURES

Loading...

Loading...