77

XC20

Use the WEIGH-IN method for adding initial refrigerant charge, and then use SUBCOOLING method for for verifying refrigerant charge.

WEIGH-IN

Liquid Line

Set Diameter

HFC-410A

(ounces per foot)

5/16”

3/8”

1/2”

0.40

0.60

1.00

NOTE - The nameplate is shown for illustration purposes only. Go to

actual nameplate on outdoor unit for charge information.

CHARGING METHOD

NOTE - Insulate liquid line when it is routed through areas where

the surrounding ambient temperature could become higher than

the temperature of the liquid line or when pressure drop is equal

to or greater than 20 psig.

Amount specified

on nameplate

Adjust amount for variation in

line set length and liquid line

diameter using table below.

Total charge

+

=

64ºF (17.7ºC) and Below

Example: Units are factorycharged for 15 feet (4.6 meters) of 3/8" line set.

Factory charge for 3/8" is 0.60 oz/ft x 15 = 9.0 ounces.

Charging Formula for Liquid Line Charge Adjustments

[(Line set oz./ft. x total length) (factory charge for line set)] = charge adjustment

Figure 56. Using HFC-410A Weigh-In Method

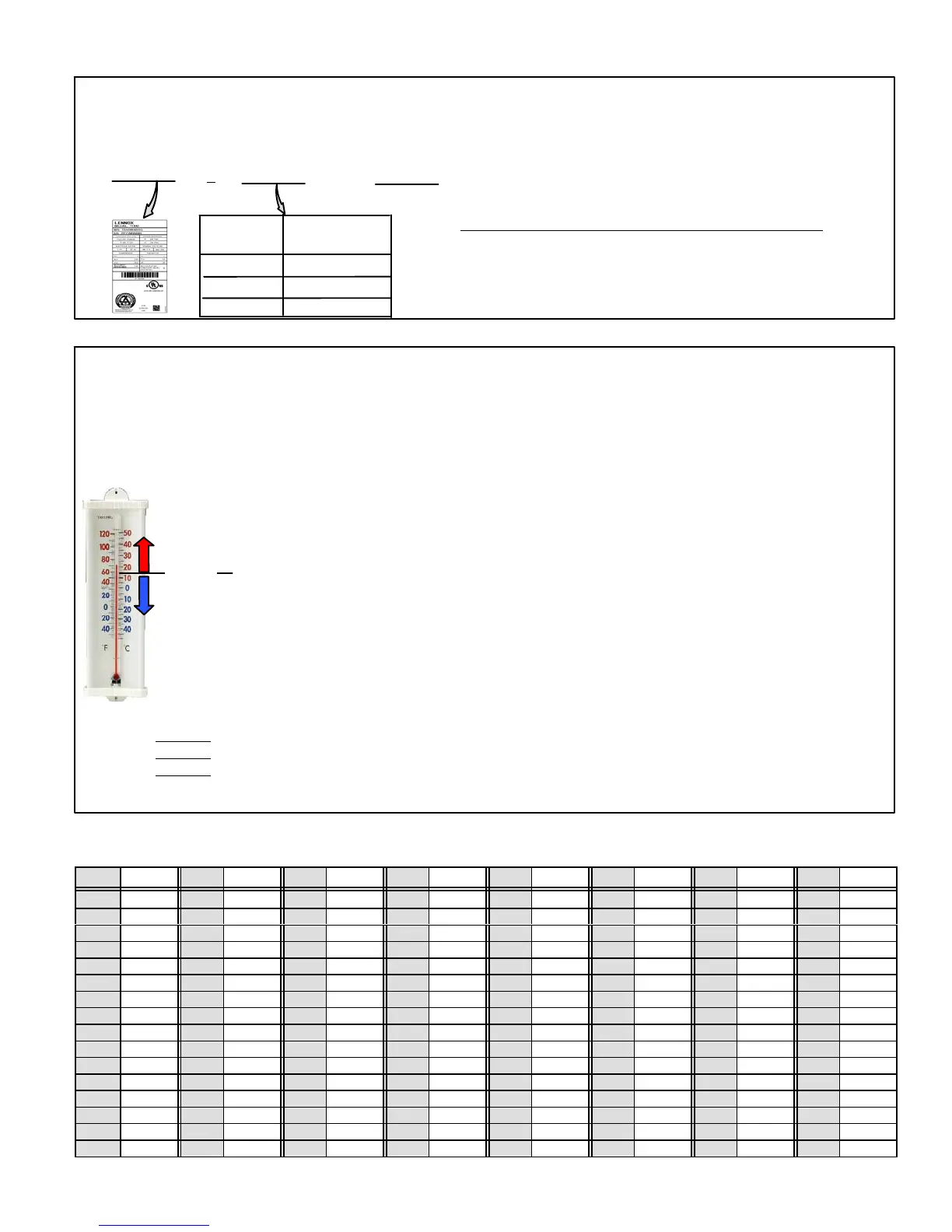

1. THE DIAGNOSTIC SCREEN ON THE THERMOSTAT OR OUTDOOR CONTROL 7-SEGMENT DISPLAY WILL SHOW INDOOR AND

OUTDOOR MOTOR CFMS OR RPMS.

2. MEASURE OUTDOOR AMBIENT TEMPERATURE; DETERMINE WHETHER TO USE COOLING MODE OR HEATING MODE TO

CHECK CHARGE.

3. CONNECT GAUGE SET.

4. CHECK LIQUID AND VAPOR LINE PRESSURES. COMPARE PRESSURES WITH EITHER HEAT OR COOLING MODE NORMAL

OPERATING PRESSURES IN THE APPLICABLE CHARGING STICKER, NORMAL OPERATING PRESSURES, HIGH STAGE.

NOTE

- THE REFERENCE TABLE IS A GENERAL GUIDE. EXPECT MINOR PRESSURE VARIATIONS. SIGNIFICANT

DIFFERENCES MAY MEAN IMPROPER CHARGE OR OTHER SYSTEM PROBLEM.

5. SET THERMOSTAT FOR HEAT/COOL DEMAND, DEPENDING ON MODE BEING USED:

USING COOLING MODE — WHEN THE OUTDOOR AMBIENT TEMPERATURE IS 60°F (15°C) AND ABOVE. TARGET

SUBCOOLING VALUES (SECOND STAGE - HIGH CAPACITY) IN APPLICABLE CHARGING STICKER ARE BASED ON 70 TO

80°F (21-27°C) INDOOR RETURN AIR TEMPERATURE; IF NECESSARY, OPERATE HEATING TO REACH THAT

TEMPERATURE RANGE; THEN SET THERMOSTAT TO COOLING MODE SETPOINT TO 68ºF (20ºC) WHICH SHOULD CALL

FOR SECOND-STAGE (HIGH STAGE) COOLING. WHEN PRESSURES HAVE STABILIZED, CONTINUE WITH STEP 6.

USING HEATING MODE — WHEN THE OUTDOOR AMBIENT TEMPERATURE IS BELOW 60°F (15°C). TARGET

SUBCOOLING VALUES (SECOND-STAGE - HIGH CAPACITY) IN APPLICABLE CHARGING STICKER ARE BASED ON 65-75°F

(18-24°C) INDOOR RETURN AIR TEMPERATURE; IF NECESSARY, OPERATE COOLING TO REACH THAT TEMPERATURE

RANGE; THEN SET THERMOSTAT TO HEATING MODE SETPOINT TO 77ºF (25ºC) WHICH SHOULD CALL FOR

SECOND-STAGE (HIGH STAGE) HEATING. WHEN PRESSURES HAVE STABILIZED, CONTINUE WITH STEP 6.

6. READ THE LIQUID LINE TEMPERATURE; RECORD IN THE LIQº SPACE.

7. READ THE LIQUID LINE PRESSURE; THEN FIND ITS CORRESPONDING TEMPERATURE IN THE TEMPERATURE/ PRESSURE

CHART LISTED IN THE APPLICABLE CHARGING STICKER AND RECORD IT IN THE SATº SPACE.

8. SUBTRACT LIQº TEMPERATURE FROM SATº TEMPERATURE TO DETERMINE SUBCOOLING; RECORD IT IN SCº SPACE.

9. COMPARE SCº RESULTS WITH APPLICABLE CHARGING STICKER, BEING SURE TO NOTE ANY ADDITIONAL CHARGE FOR

LINE SET AND/OR MATCH-UP.

10. IF SUBCOOLING VALUE IS GREATER THAN SHOWN IN APPLICABLE CHARGING STICKER FOR THE APPLICABLE UNIT,

REMOVE REFRIGERANT; IF LESS THAN SHOWN, ADD REFRIGERANT.

11. IF REFRIGERANT IS ADDED OR REMOVED, REPEAT STEPS 6 THROUGH 10 TO VERIFY CHARGE.

12. DISCONNECT GAUGE SET AND RE-INSTALL BOTH THE LIQUID AND SUCTION SERVICE VALVE CAPS.

USE

COOLING

MODE

USE

HEATING

MODE

60ºF

(15ºC)

SATº

LIQº –

SCº =

SUBCOOLING

CHARGING METHOD

(All charging MUST be performed while system is operating

either at maximum speed or 100% demand.)

Figure 57. Using HFC-410A Subcooling Method - High Speed (High Capacity)

Table 19. HFC-410A Temperature (°F) - Pressure (Psig)

°F Psig °F Psig °F Psig °F Psig °F Psig °F Psig °F Psig °F Psig

32 100.8 48 137.1 63 178.5 79 231.6 94 290.8 110 365.0

125 445.9

141 545.6

33 102.9 49 139.6 64 181.6 80 235.3 95 295.1 111 370.0 126 451.8 142 552.3

34 105.0 50 142.2 65 184.3 81 239.0 96 299.4 112 375.1 127 457.6 143 559.1

35 107.1 51 144.8 66 187.7 82 242.7 97 303.8 113 380.2 128 463.5 144 565.9

36 109.2 52 147.4 67 190.9 83 246.5 98 308.2 114 385.4 129 469.5 145 572.8

37 111.4 53 150.1 68 194.1 84 250.3 99 312.7 115 390.7 130 475.6 146 579.8

38 113.6 54 152.8 69 197.3 85 254.1 100 317.2 116 396.0 131 481.6 147 586.8

39 115.8 55 155.5 70 200.6 86 258.0 101 321.8 117 401.3 132 487.8 148 593.8

40 118.0 56 158.2 71 203.9 87 262.0 102 326.4 118 406.7 133 494.0 149 601.0

41 120.3 57 161.0 72 207.2 88 266.0 103 331.0 119 412.2 134 500.2 150 608.1

42 122.6 58 163.9 73 210.6 89 270.0 104 335.7 120 417.7 135 506.5 151 615.4

43 125.0 59 166.7 74 214.0 90 274.1 105 340.5 121 423.2 136 512.9 152 622.7

44 127.3 60 169.6 75 217.4 91 278.2 106 345.3 122 428.8 137 519.3 153 630.1

45 129.7 61 172.6 76 220.9 92 282.3 107 350.1 123 434.5 138 525.8 154 637.5

46 132.2 62 175.4 77 224.4 93 286.5 108 355.0 124 440.2 139 532.4 155 645.0

47 134.6 78 228.0 109 360.0 140 539.0

Loading...

Loading...