Commissioning

821XKlimaBA0399 5-19

Task (FIG 5 - 2 ):

Acentrifugalpump isused to ensureconstant pressureinapipeline

system (e.g. for water supply of residential and industrialpremises).

Theapplicationdoesnot onlyrequireremotecontrolfromacentral

operating panel but also setting possibilities at site. The pressure

is to be reduced to a fixed value during times when only few water

is required. By monitoring the actual pressure it is also possible to

detect burst pipes.

Functions used

- Internal PID controller for moisture control.

- Regular control, setpoint selection via fieldbus with

feedback via analog channel terminal 8.

- Networking via fieldbus (e.g. 2102).

- Manual / Remote changeover (M/R).

- Change between setpoint selection via fieldbus and

manual momentary-contact switch (terminal E1 = down,

terminal E2 = up).

- Fixed speed selection via JOG value.

- Electrical controller inhibit.

Code settings:

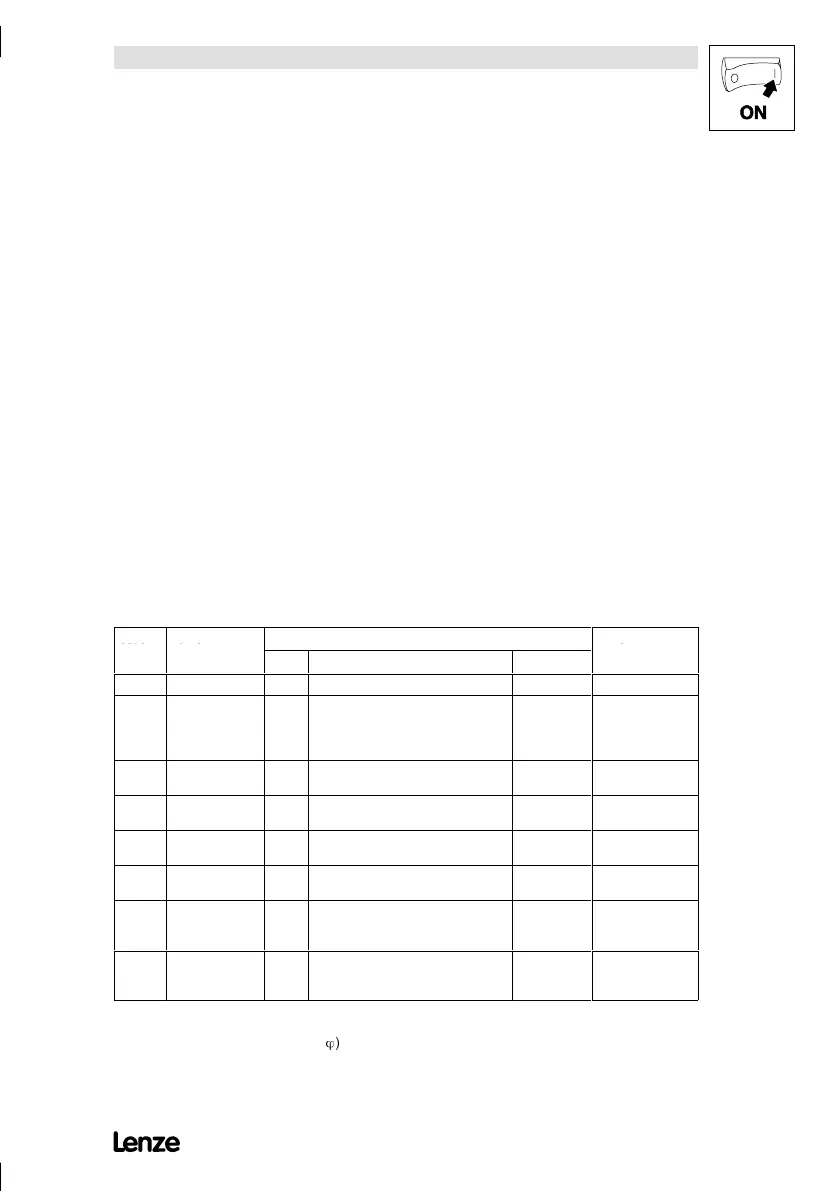

Code Name Possible settings IMPORTANT

Lenze Selection Info

C001 Operating mode -0- -3- Setpoint selection via LECOM

C005 Configuration -0- -7- Operation with closed-loop

control, setpoint via frequency

input E1 with analog feedback

via terminal 8

C007 Te rmi na l

configuration

-0- -26- Motorpotentiometer, JOG, CW/

CCW

C037 JOG value 1 20.00 16.67Hz Fixed reduction to 1/3 of the

rated speed.

C051 Actual PID

controller value

Only display

C070 Gain

PID controller

1.00 1.00

C071 Integral action

time

PID controller

100 100 ms

C072 Differential

component

PID controller

0.0 0.0

All other parameters are based on the factory setting. Set the rated motor data (depends on the motor used)under C088

(rated motor current) and C091 (motor cos

Ö

). The pressure setpoint cannot only be selected via a fieldbus but also via

the operating unit8201 BB (installationupto 10 mdistance possible)or ananaloginput signal (with module 8279). For

standardisation of the process value see chapter 5.5.1 .

Loading...

Loading...