Safety information

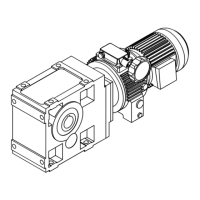

Lenze low-voltage machinery

4

l

EDK82MVXXX EN 1.0

1.2 General safety and application notes for Lenze low-voltage

machinery

(in c onformity with the Low-Voltage Directive 73/23/EEC)

1. General

Low-voltage machines have dangerous, live and rotating parts as well as possibly hot surfaces. All operations serving transport, connection, commissioning and

maintenance are to becarried out byskilled, responsible tec hnical personnel (obse rve EN 50110-1(VDE 0105-100); IEC60364). Improper handling cancause severeinjuries

or damages.

Synchronous machines induce voltages at open terminals during operation.

2. Application as directed

These low-voltage machines are intended for industrial and co mmerci al installations. They comply with the harmonized standards of the series EN 60034 (VDE O53O).

Their use in hazardous areas is prohibited unless they are expressly intended for such use (follow additional instructions).

The enclosures ≤IP23 are byno means intendedfor outdoor use. Air-cooleddesigns are ratedforambienttemperaturesbetween -15 °C and-10 °Cand+40°C and altitudes

≤ 1000 m a .m.s.l., from -20 °C to +40 °C without brake or with spring-operated brake, with separate ventilation or self ventilation, from -15 °C to +40 °C with permanent

magnet brake and from -10 °C to +40 °C with separate fan. Check i ndicati ons on the nameplate and if they are different, observe them. The conditions on site must

correspond to all nameplate data.

Low-voltage machines are components for the installation into machines as defined in the Machinery Directive 98/37/EC. Commi ssioning is prohibited until the conformity

of the end product with this Directive has been established (follow a.o. EN 60204-1).

The integrated brakes cannot be used as safety brakes. It cannot be ruled out that factors which c annot be influenced, such as oil ingression because of a defective A-side

shaft seal, cause a torque reduction.

3. Transport, storage

The forwarder must be informed directly after receipt of the goods about all dama ges or deficiencies; if necessary, commissioning must be stopped. Tighten screwed-in

ring bolts before transport. They are designed for the weight of the low-voltage machine, do not apply extra loads. If necessary, use suitable and adequately dimensioned

means of transport (e.g. rope guides).

Remove the shipping brace before commissioning. Reuse it for further transports. For storage of low-voltage machines ensure a dry, dust-free and low-vibration

(v

rms

≤ 0.2 mm/s) environment (danger of bearing damage at rest). Measure the insulation resistance before commissioning. If the values are ≤ 1kΩ per volt of rated

voltage, dry the winding.

4. Installation

Ensure an even surface, solid foot or flange mounting and exact alignment if a direct clutch is connected. Avoid resonances with the rotational frequency and double mains

frequency whi ch may be caused by the assembly. Turn rotor by hand, listen for unusual slipping noises. Check the direction of rotation when the clutch is not active(observe

section 5).

Use appropriate tools to mount or remove belt pulleys and clutches (heat generation!) and cover them with a touch guard. Impermissi ble belt tensions must be avoided

(technical list).

The machines are half-key bal anced. The clutch must be half-key balanced, too. The visibly protruding part of the key must be removed.

If required, provide pipe connections. Mounti ng positions with shaft end at top must be protected with a c over which avoids the ingression of foreign particles into the fan.

Free circulation of the cooling air must be ensured. The exhaust ai r - al so the exhaust air of other machines next to the drive system - must not be immediately taken in

again.

5. Electrical connection

All operations must be carriedout only by qualified and skilled personnel when the low-voltage machine isat standstill and when the machine is de-energized andprotected

against unintentional restart. This also applies to auxiliary circuits (e.g. brake, encoder, separate fan).

Check safe isolation from the supply!

If the tolerances in EN 60034-1; IEC 34 (VDE 0530-1) - voltage ±5 %, frequency ±2 %, waveform, symmetry - are exceeded, more heat will be generated and the

electromagnetic compatibility will be influenced.

Observe the indications on the nameplate, operating notes, and the connection diagram in the terminal box.

The connection must ensure a conti nuous and safe electrical supply (no loose wire ends); use appropriate cable terminals. The connection to the PE conductor must be

safe. The plug-in connector must be screwed up tightly (to stop).

The clearances between bare, live parts and earth must not fall below: 8 mm at V

rated

≤ 550 V, 10 mm at V

rated

≤ 725 V, 14 mm at V

rated

≤ 1000 V.

The terminal box must be clean and dr y; foreign particles, dirt and moisture affect operation. All unused cable entries and the box itself must be sealed against dust and

water. For the trial run without output elements, lock the key. Check brake operation before the commissioning of lo w-voltage machines with brakes.

6. Operation

Vibration severities v

rms

≤ 3.5 mm/s (P

rated

≤ 15 kW) or 4.5 mm/s (P

rated

> 15 kW) are acceptable when the clutch is activated. If deviations from normal operation occur,

e.g. increased temperature, noise, vibration, find the cause and, if necessary, c ontact the manufacturer. Switch-off the machine in problematic situations.

If the drive is exposed to dirt, clean it regularly.

Do not switch-off the protection devices, not even for trial runs.

Integrated temperature sensors do not provide full protection. If necessary, limit the maximum current. Connect the function blocks to the option switch-off after several

seconds of operation at I > I

rated

, especially if blocking may occur.

Shaft seals and bearings have a limited service life.

Regrease the bearings using the relubrication facility while the low-voltage machine is running. Observe the saponifica tion number. If the grease drain hole is sealed with

a pl ug (IP54 drive e nd; IP23 drive end and non-drive end), remove the plug before commissioning. Seal the bore holes with grease. Replac e the prelubri cated bearings

(2Z-bearings) after approx. 10.000 h - 20.000 h, at the latest however after 3 - 4 years. Observe the manufacturer’s instructions.

efesotomasyon.com - Lenze

Loading...

Loading...