OSFLO ADAPTER INSTALLATION:

1. Position the adapter half with the insert nipple to the end of the luminaire or electrical box to determine if

sensor will be positioned correctly for optimum coverage.

2. If appropriate position for coverage, insert the snap fitting into the knockout of the luminaire or electrical

box (if added depth is needed for coverage, use the OSFOA with multiple positions).

3.

Remove the locknut from the sensor and insert the wire leads through the mounting hole of the other half

of the adapter. Slide locknut over wire leads and thread onto threaded sensor nipple and tighten so that

sensor does not move. Align sensor so that it is parallel to the bottom of the luminaire or electrical box.

4. Feed the sensor wire through the adapter half mounted on the luminaire or electrical box and into the

wire access area.

5. Snap the adapter half with the sensor attached to the adapter half on the luminaire or electrical box by

aligning the snap fittings and pushing firmly together

.

6. Connect per Wiring Diagram as follows: BLACK lead to LINE (Hot), RED lead to LOAD, WHITE

lead to LINE (Neutral). Twist strands of each lead tightly and with circuit conductors, push firmly into

appropriate wire connector. Screw connector on clockwise making sure no bare wires show below

the connector.

7. Restore power at circuit breaker or fuse.

NOTE: Allow approximately 1 minute for charge-up. If the lights turn ON and the LED blinks when

a hand is waved in front of the lens, then the Sensor was installed properly. If the operation is

different, refer to the Troubleshooting Section.

SETTINGS

Time-Delay: Settings should be determined during the installation

period. This adjustment controls the amount of time the lights stay

ON after the last detected motion. You may select settings varying

from 30 seconds to 20 minutes and any time in between.

NOTE: After power is turned ON, allow two minutes for this unit to

warm up before performing Time-Delay settings.

TROUBLESHOOTING

• Lights will not turn ON

- Circuit breaker or fuse is OFF: Turn the breaker ON. Ensure the lights being controlled are in

working order (i.e., working bulbs, ballasts, etc.)

- Sensor is wired incorrectly or may be defective: Confirm that the sensor’s wiring is done

correctly and inspect visually for problems.

- Lens is dirty or obstructed: Inspect the lens visually and clean if necessary, or remove the

obstruction.

• Lights will not turn OFF

- Sensor is wired incorrectly or may be defective: Confirm that the sensor’s wiring is done

correctly and inspect visually for problems.

- Sensor may be mounted too closely to an air conditioning or heating vent: Move the

sensor or close the vent.

- The line voltage has dropped: Perform the necessary tests to ensure the line voltage has not

dropped beneath 100V.

• Lights turn OFF and ON too quickly

- Sensor may be mounted too closely to an air conditioning or heating vent: Move the

sensor to another location or close the vent.

- Time delay set improperly: Adjust the TIME DELAY.

PK-93439-10-00-5H

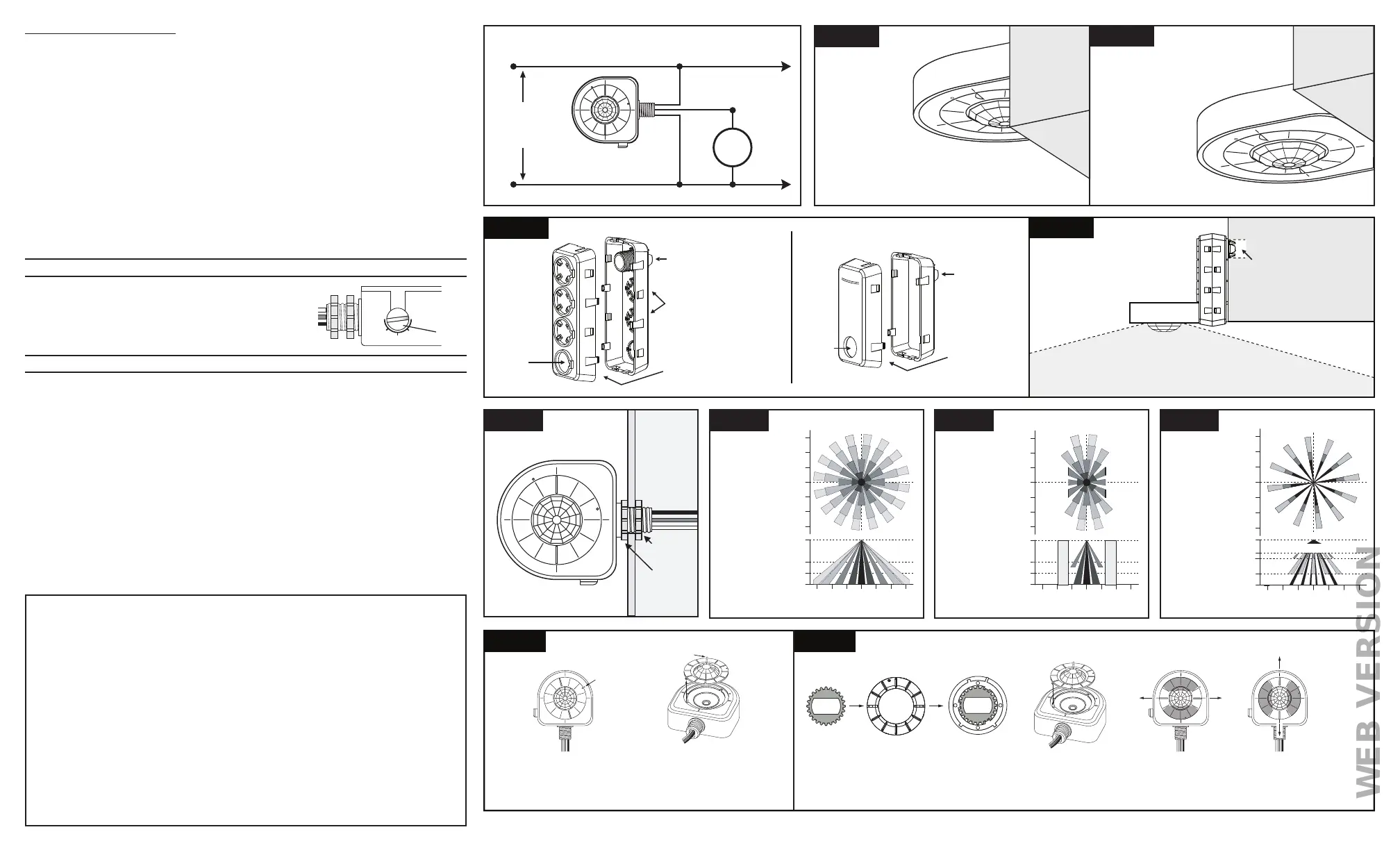

Wiring Diagram

Hot (Black)

Neutral (White)

Load

Red

White

White

Sensor

Black

Black

Line

120-347VAC,

50-60Hz

30 SEC.

20 MIN.

TIME DELAY

10

15

5

Timer

dial

Figure 2A

Sensor

mounts

here

(non-keyed) hole

Wires from

sensor to

luminaire or

electrical

box are fed

through adapter

Alternate keyholes

for height adjustment

OSFOA-00W

Adapter

Threaded snap-in nipple

attaches to 1/2" luminaire

or electrical box trade-size

knockout holes

Wires from

sensor to

luminaire or

electrical

box are fed

through adapter

Insert nipple

attaches to

1/2" luminaire

or electrical box

trade-size

knockout holes

Sensor

mounts

here

(non-keyed)

hole

OSFLO-00W

Adapter

Figure 2B

OSFOA-00W

Adapter

(shown)

Sensor

Adapter allows sensor to be mounted

to achieve optimum field-of-view

1/2"

trade-size

knockout

hole

© 2021 Leviton Mfg. Co., Inc.

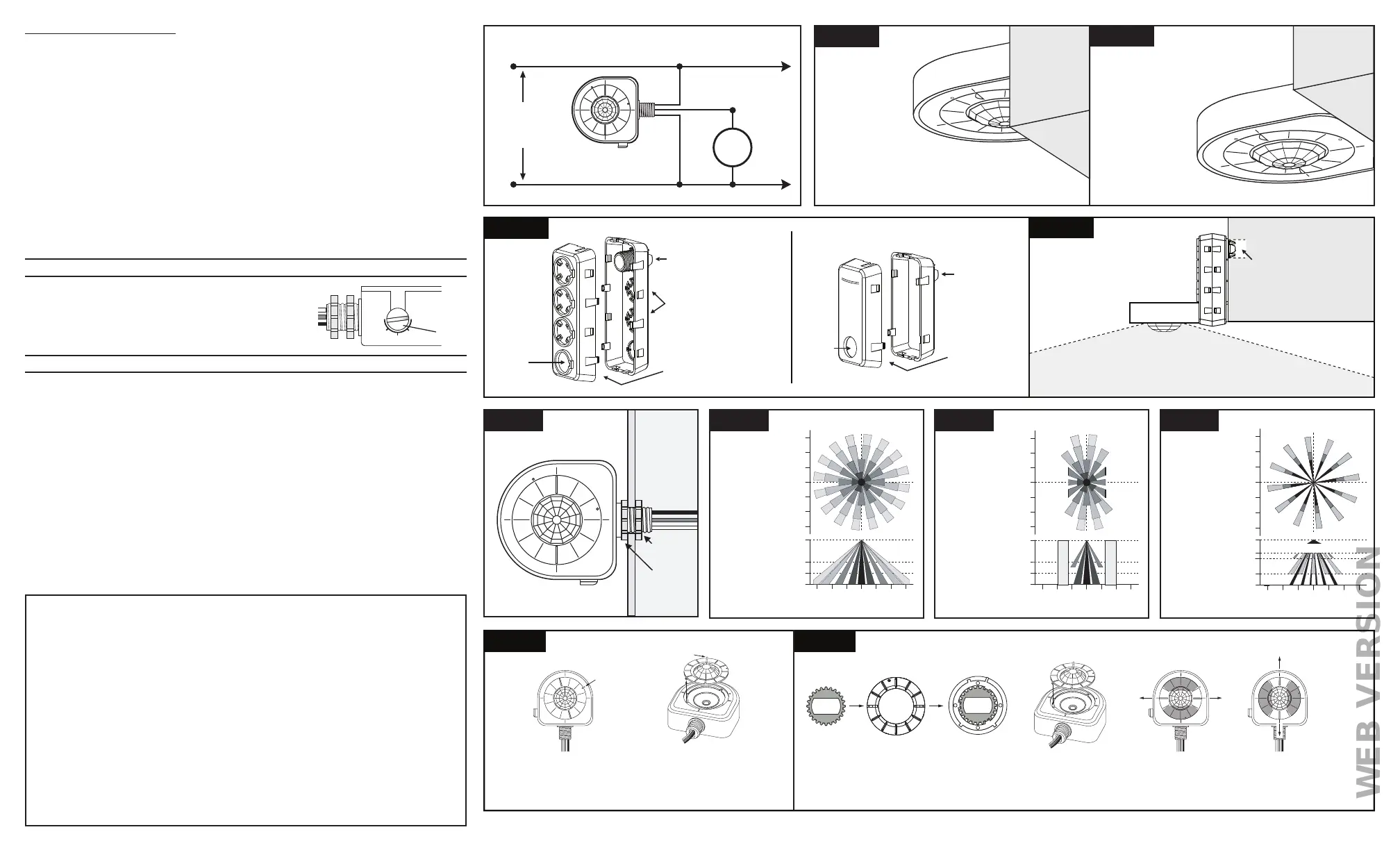

Figure 7A Figure 7B

Line up dots

Dots

Pull up on tab to remove 360

˚

lens

(High Bay or Low Bay)

Tab

Positon aisle mask for applicationInsert aisle mask into lens assembly

(if applicable)

Line up dots and

turn to set lens

Figure 1B

Figure 1A

Sensor mounted too high

Outer beams are obstructed

Field-of-view is limited

INCORRECT

Sensor mounted within 1" of bottom

No obstruction

Optimum field-of-view

CORRECT

FCC Statement: This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and,

if not installed and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

FCC CAUTION

Any changes or modifications not expressly approved by Leviton Manufacturing Co., could void the user’s authority

to operate the equipment.

IC Statement: This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject

to the following two conditions: (1) this device may not cause interference, and (2) this device must accept any

interference, including interference that may cause undesired operation of the device.

FCC Suppliers Declaration of Conformity (sDoC): High Bay/Low Bay Passive Infrared Occupancy Sensor and Offset

Adapter are manufactured by Leviton Manufacturing, Inc., 201 N Service Road, Melville, NY 11747. www.Leviton.com.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

Figure 4

9.1m (30 ft)

9.1m

(30 ft)

9.1m

(30 ft)

9.1m (30 ft)

9.1m (30 ft)

12.2m (40 ft)

6.1m (20 ft)

6.1m

(20 ft)

6.1m

(20 ft)

6.1m (20 ft)

6.1m (20 ft)

3m (10 ft)

3m (10 ft)

3m

(10 ft)

3m

(10 ft)

0

0

0

White

High Bay

360

˚

Top View

Side View

Figure 5

9.1m (30 ft)

9.1m

(30 ft)

9.1m

(30 ft)

9.1m (30 ft)

9.1m (30 ft)

12.2m (40 ft)

6.1m (20 ft)

6.1m

(20 ft)

6.1m

(20 ft)

6.1m (20 ft)

6.1m (20 ft)

3m (10 ft)

3m (10 ft)

3m

(10 ft)

3m

(10 ft)

0

0

0

Side View

S

H

E

L

V

E

S

S

H

E

L

V

E

S

Figure 6

Blue

Low Bay

360

˚

Top View

Side View

Aisle Mask

Top View

Figure 3

Inside of

Luminaire

or

Electrical

Box

Sensor

Wires

Tightening

Lock-Nut

Stopping

Lock-Nut

9.1m (30 ft)

9.1m (30 ft)

6.1m (20 ft)

6.1m (20 ft)

3.0m (10 ft)

3.0m (10 ft)

0

6.1m (20 ft)

7.6m (25 ft)

2.4m (8 ft)

0

3.7m (12 ft)

9.1m

(30 ft)

9.1m

(30 ft)

6.1m

(20 ft)

6.1m

(20 ft)

3.0m

(10 ft)

3.0m

(10 ft)

0

*Not recommended for aisleway applications under 12ft mounting height

Loading...

Loading...