5.3 Mounting of Pump Head

5.3.1 Preparation

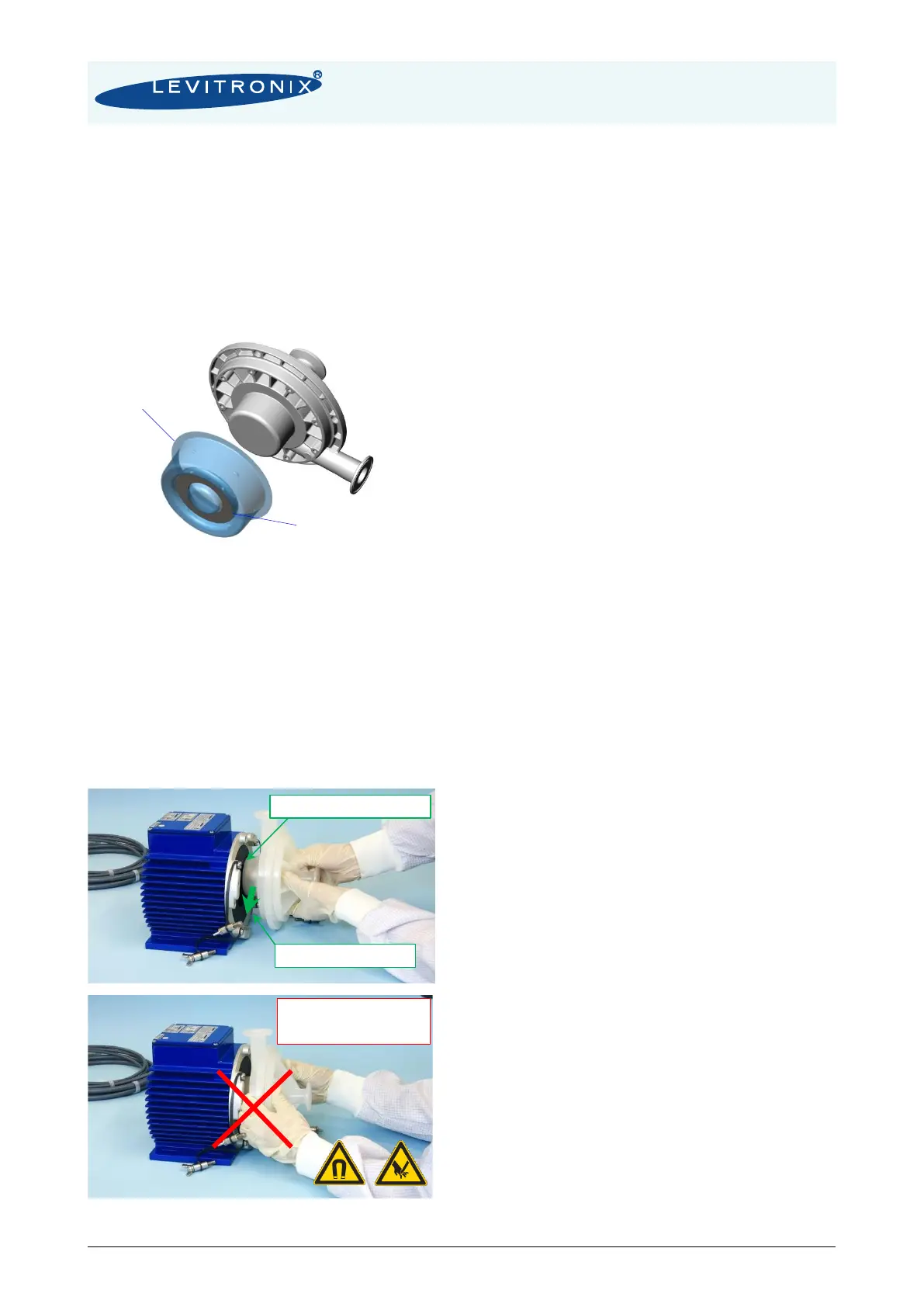

After removal of the pump head from its

packaging assure that no metallic part is

magnetically attaching. Specifically remove the

Protective Cup, which comes delivered within the

packaging in order to magnetically fix the impeller

against movements and protect the pump head

bottom during handling and transportation.

Figure 39: Pump head with Protective Cup

Assure that the impeller speed is set to 0 rpm and

that the system is disabled.

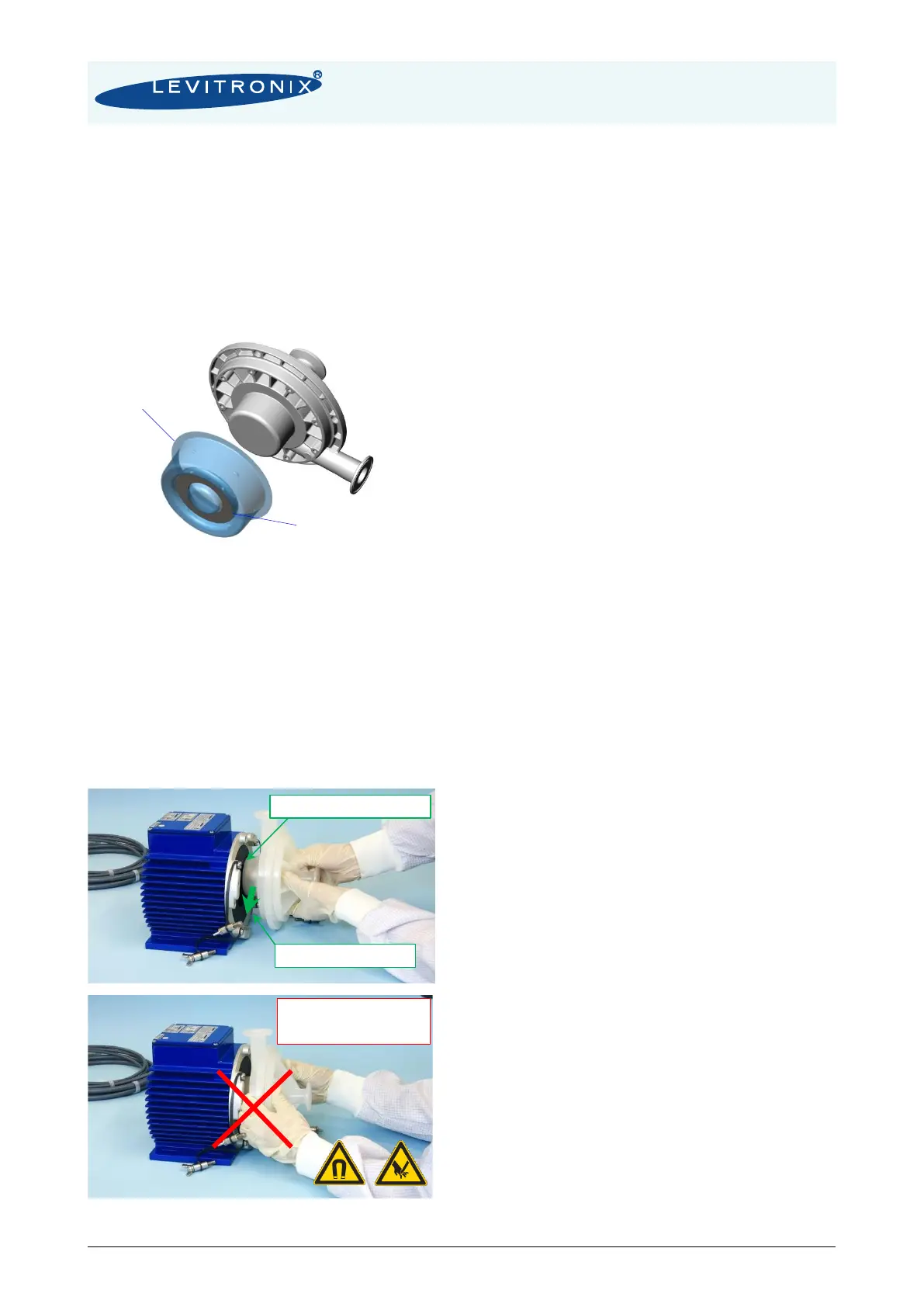

5.3.2 Mounting Step 1: Insertion

To avoid squeezing the fingers by the magnetic

forces, do not directly insert the pump head into

the motor cavity and do not hold it on the bottom

side during insertion. First place the pump head

on the top of the motor by holding it below the

inlet fitting. Then move it sideways into the motor

cavity.

Figure 40: Insertion of pump head.

5.3.3 Mounting Step 2: Manual Screw Fixation

Align the pump head holes with the threads of the

pump head socket. Hand tighten the 4 screws.

5.3.4 Mounting Step 3: Ready-to-Use Check

Check that the pump head is properly aligned with

the Pump Head Socket.

5.4 Removal of Pump Head

5.4.1 Preparation

Set the speed to 0 rpm and disable the system.

After running at higher motor or liquid temperature

the pump head might stick to the motor due to

thermal expansion effects. Let the system cool

down before starting the removal procedure.

5.4.2 Removal Step 1: Remove the Screws

Remove the 4 manual screws.

5.4.3 Removal Step 2: Axial Removal

Smoothly remove the pump head following the

precautions and steps described in Section 5.3.2.

5.4.4 Removal Step 2: Protective Cup

It is recommended to attach the Protective Cup

(see Figure 39) to the pump head bottom in order

to minimize magnetic leakage fields surrounding

the impeller and hence reducing the tendency to

attract other magnetic parts.

5.5 Assembly into Circuit

The following points shall be considered, when

integrating the pump head into a single-use

circuit.

5.5.1 Usage of Protective Cup

During handling, assembling and transportation of

the pump head with the hydraulic circuit, it is

recommended to attach the Protective Cup (see

Figure 39) with the integrated fixation disc to the

pump head bottom. The fixation disc holds the

impeller mechanically in place and reduces the

magnetic fields, which can attract other magnetic

parts during handling, sterilization and transport.

The protective cup avoids that the pump head

bottom is damaged.

5.5.2 Careful with Multiple Pump Heads

Take care to the magnetic forces of the

impellers when handling multiple pump heads

at the same time. Avoid two pump heads coming

together with force due to the magnetic attraction,

which might cause cracks.

5.5.3 Avoidance of Mechanical Stress

Avoid applying too much mechanical stress to

the pump head for example, by excessively

squeezing it with the other parts of the circuit into

packaging or an enclosed space of limited size,

or by applying too much tension or perpendicular

force to the fittings.

Loading...

Loading...