Static Electricity

The pump must be connected with a low impedance to ground so as to

avoid charging with static electricity. This is attained by properly connecting

the protective ground conductor at the point provided for it. During normal

operation no dangerous creation of charges will occur.

In connection with ATEX usage, the electrically conducting link between all

pump chamber cover, exhaust flange and gear housing is absolutely manda-

tory! After any assembly work on the pump chamber, this link must be

checked. For this, use a resistance meter and measure the resistance of the

link which must be less than 100 Ohm.

A filter on the intake side must be connected to ground in accordance with

the Operating Instructions of the filter.

Use only the original spare parts from Leybold.

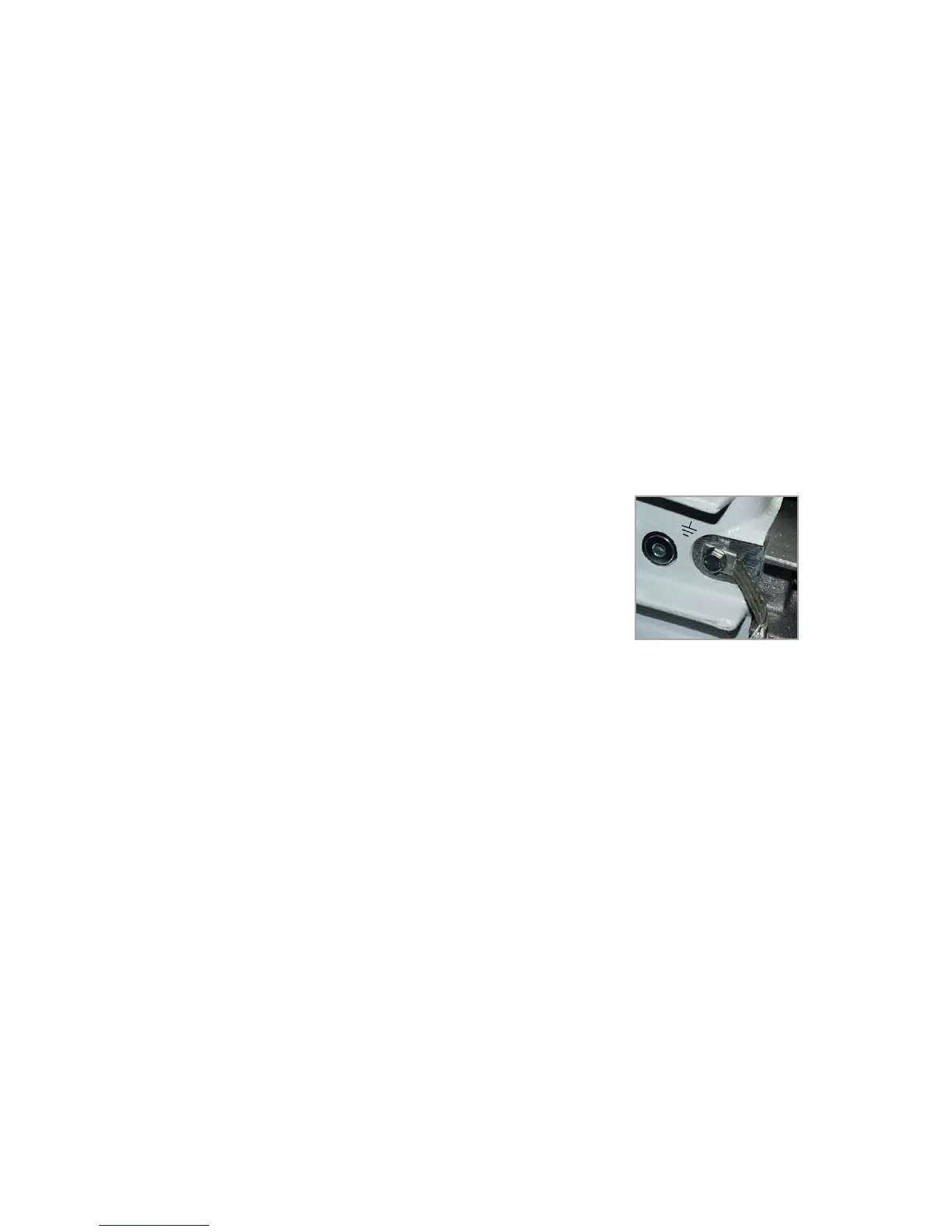

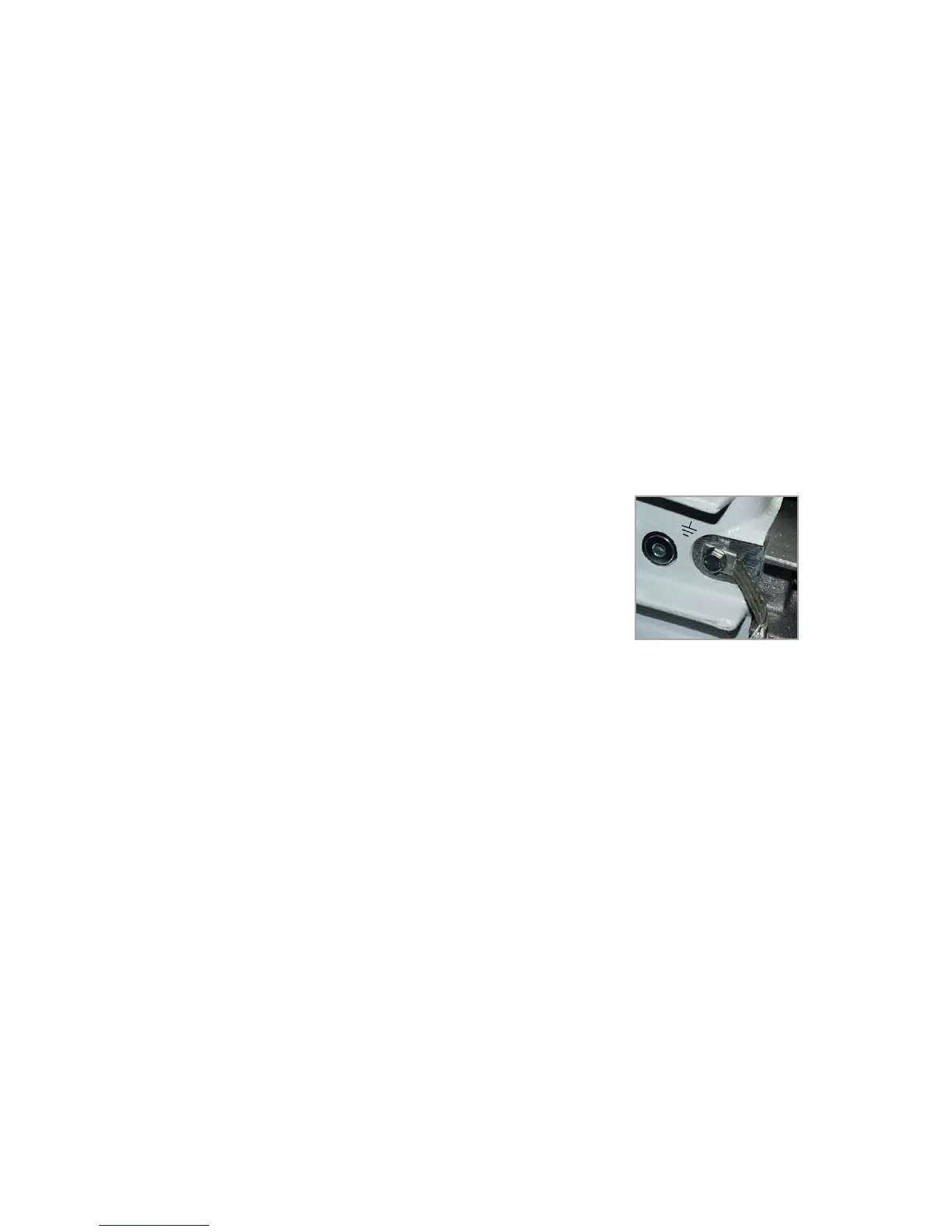

Ground Connection

Between the M 8 tapped blind hole on the pump (see figure) and the frame

ground/ground rail of the frequency converter, an EMC compliant ground

connection (copper strap, for example) must be provided.

Chemical Reactions

The pump shall not come in to contact and shall not be used in connection

with reactive or corrosive gases which may cause an exothermal chemical

reaction.

Additional Safety Measures

Overheating of the pump can give rise to temperatures which exceed the

certified maximum surface temperature.

Compliance with the operating parameters stated in these Operating

Instructions must be ensured.

Run checks on a regular basis and comply with the maintenance schedule.

Additional Maintenance Requirements

In those cases where dust may deposit itself on the pump or the motor sur-

faces, measures must be introduced which ensure that such deposits are

removed on a regular basis.

In order to ensure that the defined level of safety is maintained, only accesso-

ry parts and wearing parts from Leybold must be used.

Connect ground strap here!

Loading...

Loading...