3.4.2 Star/Delta Start-up Circuit

In the case of this circuit (star circuit) a lower voltage is applied to the motor

coils upon switching on, resulting in a lower switch-on current.

During this phase also power and torque of the motor are lower.

In order to attain the operating levels for torque and power rapidly, the start-

up phase should be as short as possible, approximately 4 to 5 seconds.

Thereafter the switchover to continuous operation (delta circuit) should occur.

Here also a motor protection switch for heavy run-up (class 20) should be

used.

3.4.3 Soft Start

In order to reduce the current taken up from the mains supply, the supply

voltage to the motor may be electronically controlled during the start-up time.

Within the starting time, the motor must reliably reach its nominal values. The

adjustable starting voltage should be 60% of the nominal voltage. The ramp

time should be 15 seconds.

The highest switch on currents (140 A/400 V) must be taken account when

selecting the soft starting unit (Siemens 3RW30, for example). In addition,

note the installation instructions of the soft starter manufacturer.

3.4.4 Mains Connection

The mains power needs to be supplied via an external mains switch with ON/

OFF key by the customer.

The mains connection needs to be provided in accordance with the type of

motor protection. The mains supply must match the mains power rating of

the motor.

The line cross-section for the mains power supply needs to be calculated in

consideration of the cable length and the available mains circuit breaker.

Using a mains power supply line having a cross-section of at least 4 x 6 mm

2

is recommended.

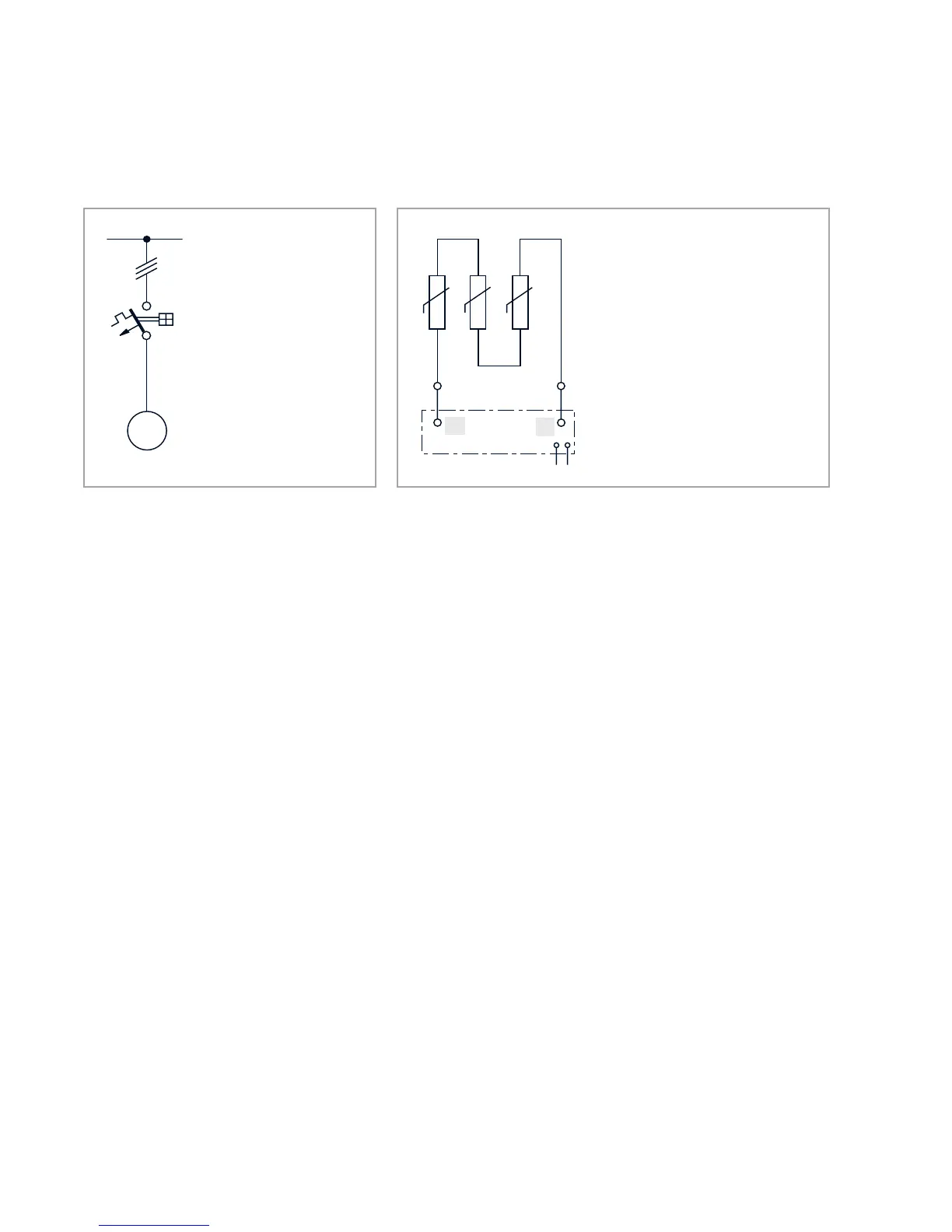

Fig. 3.2 Example for PTC temperature sensor circuit

Protection arrangement

PTC temperature sensor with controller

Protection against:

- Overload during cont. operation

- Long starting up and stopping

processes

- High switching frequency

in the case of faults against:

- Obstructed cooling

- Increased temperature of the coolant

- Single-phase operation

- Frequency fluctuations

- Switching to a seized rotor

10

11

+

+

+

2.5 V max.

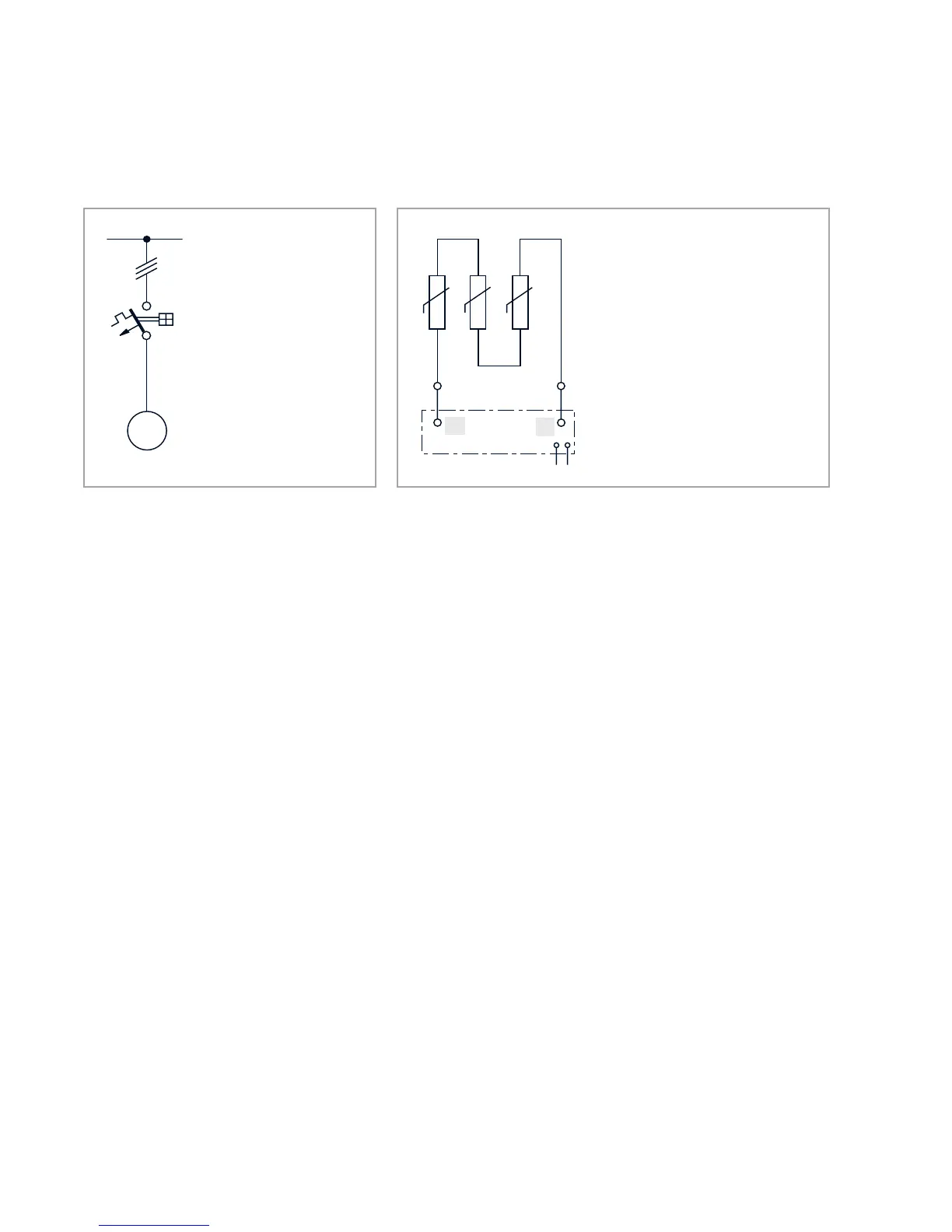

Fig. 3.1 Examples of motor protection circuits

Protection arrangement

Motor protection switch with

thermal and solenoid overcur-

rent release (class 20).

Protection against:

Overload during continuous

operation

Seized rotor

M

3 ~

Loading...

Loading...