19

GA 01.600/10.02 - 07/01

Checking / Maintenance

3.2 Oil Change

Before pumping oxygen (or other highly

reactive gases) at concentrations excee-

ding the concentration in the atmosphere

(> 21 % for oxygen) it will be necessary to

use a special pump. Such a pump will have

to be modified and de-greased, and an inert

special lubricant (like PFPE) must be used.

For proper operation of the pump, it is essential that the

pump has an adequate supply of the correct and clean

oil at all times.

The oil must be changed when it looks dirty or if it

appears chemically or mechanically worn out (see Sec-

tion 3.1.1).

The oil should be changed after the first 100 operating

hours and then at least every 2,000 to 3,000 operating

hours or after one year. At high intake pressures and

intake temperatures and/or when pumping contaminated

gases, the oil will have to be changed much more fre-

quently.

Further oil changes should be made before and after

long-term storage of the pump.

Only change the oil after the pump has

been switched off and while the pump is still

warm.

Required tool: Allen key 8 mm.

Remove the oil drain plug (7/4) and let the used oil drain

into a suitable container. When the flow of oil slows

down, screw the oil drain plug back in, briefly switch on

the pump (max. 10 s) and then switch it off again. Remo-

ve the oil drain plug once more and drain out the remai-

ning oil.

Screw the oil drain plug back in (check the gasket and

reinstall a new one if necessary).

Remove the oil fill plug (7/1) and fill in fresh oil.

Screw the oil fill plug (7/1) back in.

If there is the danger that the operating

agent may present a hazard in any way due

to decomposition of the oil, or because of

the media which have been pumped, you

must determine the kind of hazard and

ensure that all necessary safety precau-

tions are taken.

We can only guarantee that the pump ope-

rates as specified by the technical data if

the lubricants recommended by us are

used.

3.2.1 Disposal of Used Pump Materials

The corresponding national environmental and safety

regulations apply. This applies equally to used filters and

filter elements (oil filter, exhaust filter and dust filter).

- In the case of hazardous substances

determine the kind of hazard first and

observe the applicable safety regulations.

If the potential hazard still persists, the

pump must be decontaminated before

starting with any maintenance work. For

professional decontamination we recom-

mend our Leybold service.

- Never exchange the oil or the filters while

the pump is still hot. Let the pump cool

down to uncritical temperatures first. You

must wear suitable protective clothing.

Caution

Warning

Caution

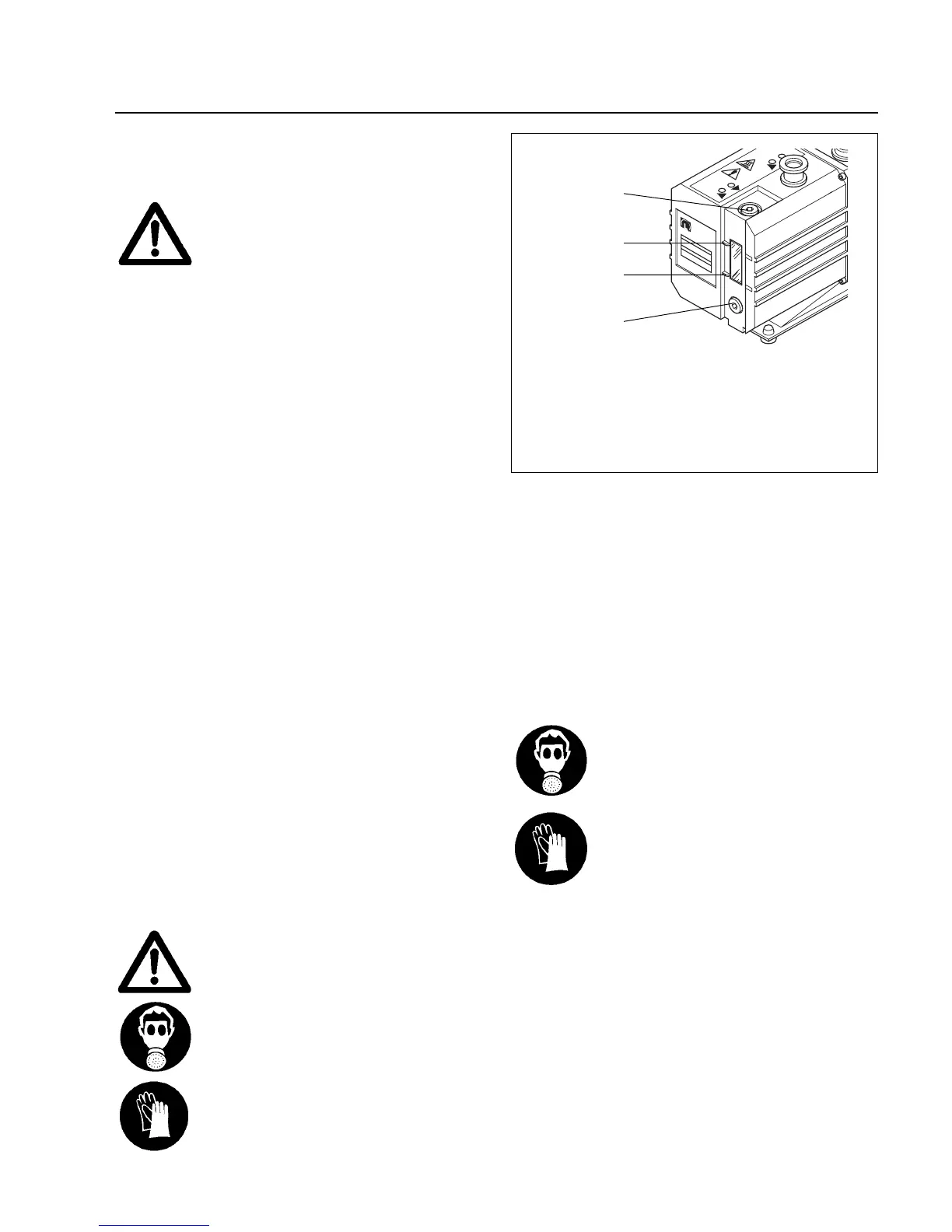

Fig. 7 Oil change

Key to Fig. 7

1 Oil fill plug

2 Oil level mark “maximum”

3 Oil level mark “minimum”

4 Oil drain plug

Loading...

Loading...