20

GA 01.600/10.02 - 07/01

Checking / Maintenance

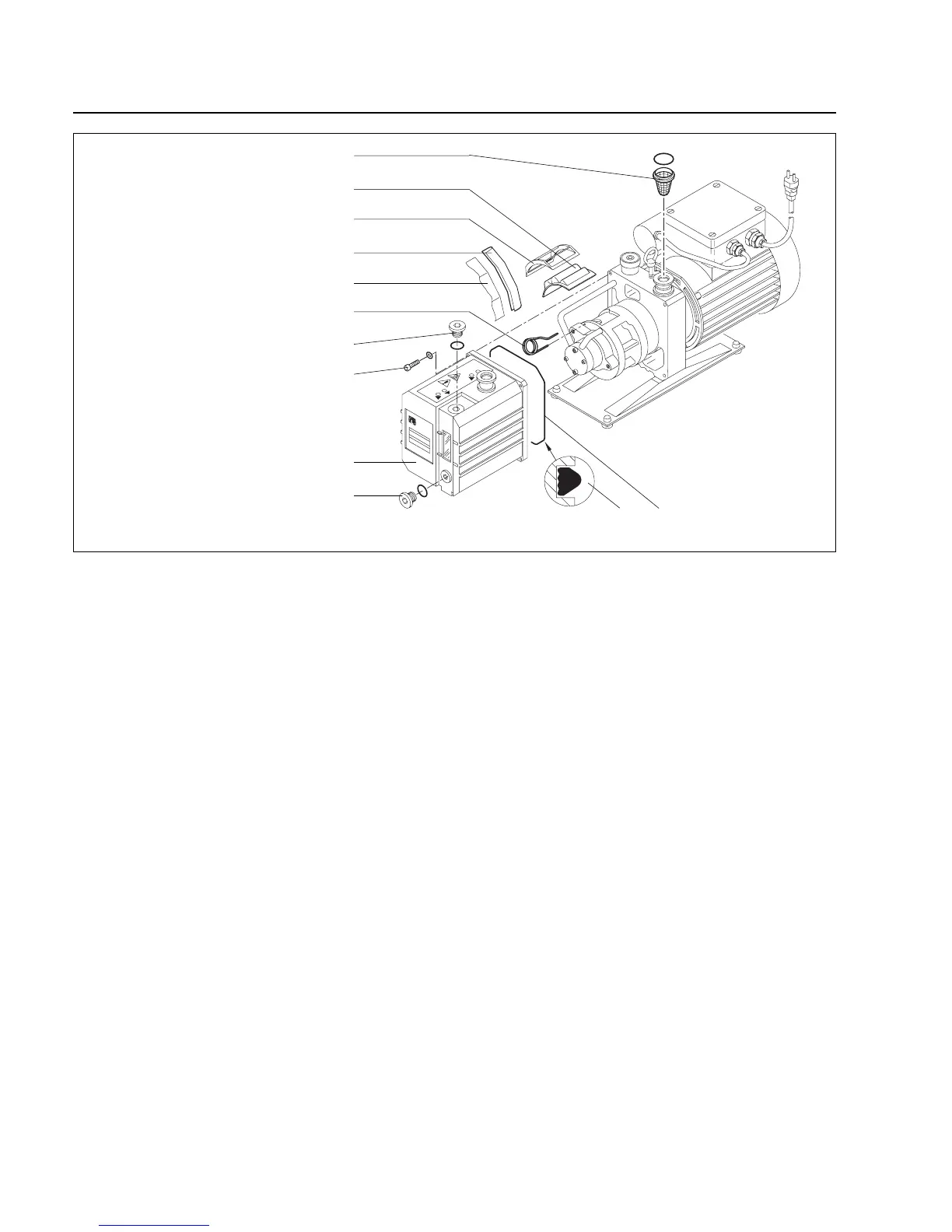

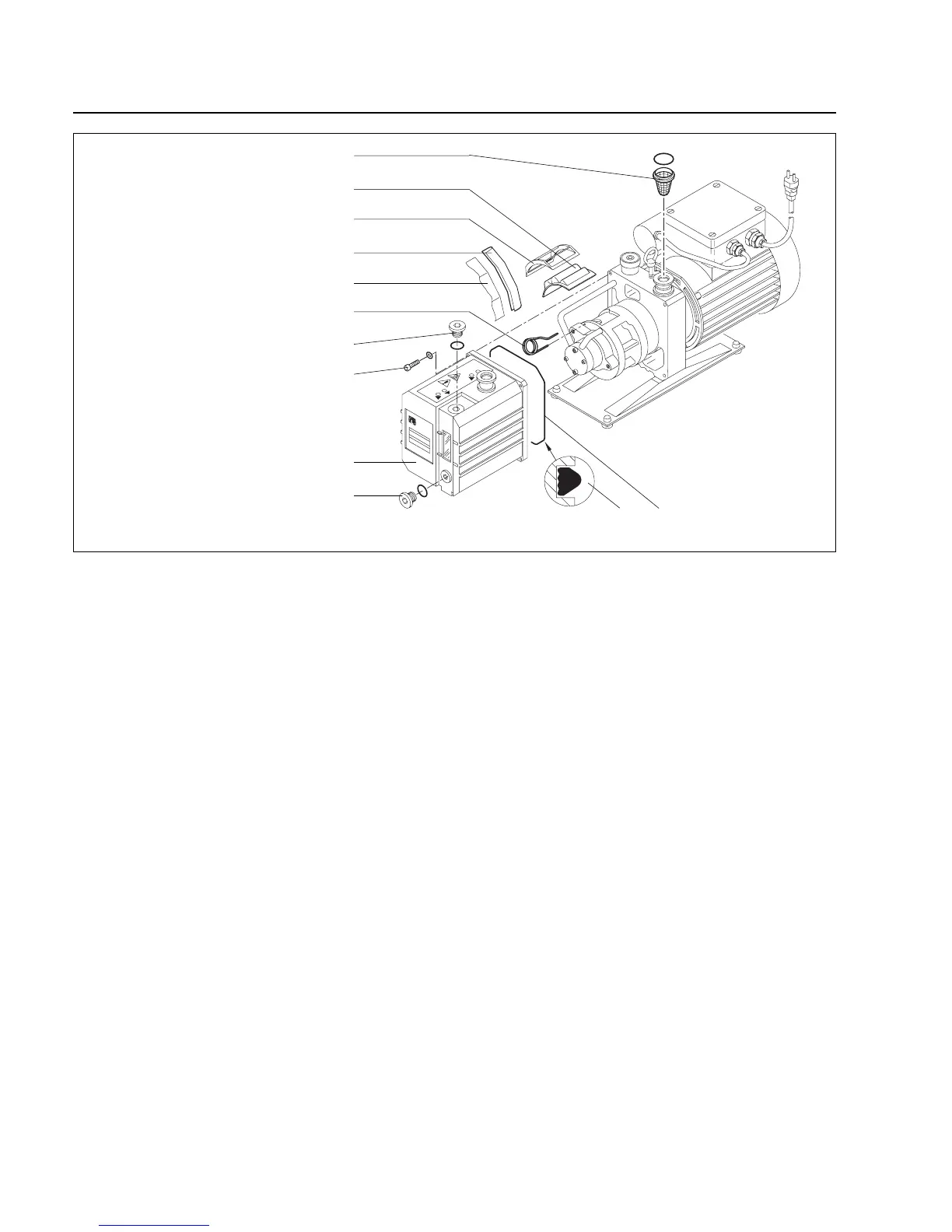

3.3 Cleaning the Dirt Trap

Located in the intake port is a wire mesh sieve acting as

a dirt trap (8/10) for foreign objects. This sieve must be

kept clean in order to avoid any throttling of the pump.

To clean the dirt trap remove it from the intake and clean

it in a vessel using a solvent. Then thoroughly dry it with

compressed air. If the dirt trap is faulty you must replace

it.

Adapt the cleaning intervals according to

the requirements. If large quantities of abra-

sive materials are involved you should

install a dust filter in the intake line.

3.4 Removing and Inserting

the Internal Demister

Simple maintenance on the side of the pump using

Maintenance Kit 1

Required tools:

Allan keys 4 and 8 mm

The internal demister has been installed in a resiliant

frame.When it has clogged it will lift itself up periodically

at high intake pressures in order to equalise the resulting

pressure difference.

The increased noise level at high intake pressure is thus

a sign for a clogged internal demister.

Depending on the operating conditions the internal demi-

ster will have to be cleaned regularly or it must be

exchanged. Cleaning must be performed using a suitable

solvent.

Switch the pump off and drain out the oil (in accordance

with Section 3.2).

In order to collect the remaining oil in the oil box we

recommend that you lift the pump up slightly at the side

of the motor.

Unscrew the four hex. socket screws (8/3) of the oil box.

Pull the oil box (8/2) out to the front.

Remove the gasket (8/11) of the oil box.

Use a pair of pliers to pull the spring (8/5) out to the front.

Detach the holding frame (8/8) and the internal demister

(8/9).

Clean all parts and check them for perfect condition and

replace them as required.

Reassemble in the reverse order.

Make sure to fit the gasket for the oil box

(8/11) with the flat side in the groove, see

item 12 in Fig. 8.

Torque for the hex. socket screws (8/3) is

5.5 Nm.

Loading...

Loading...