24

GA 01.600/10.02 - 07/01

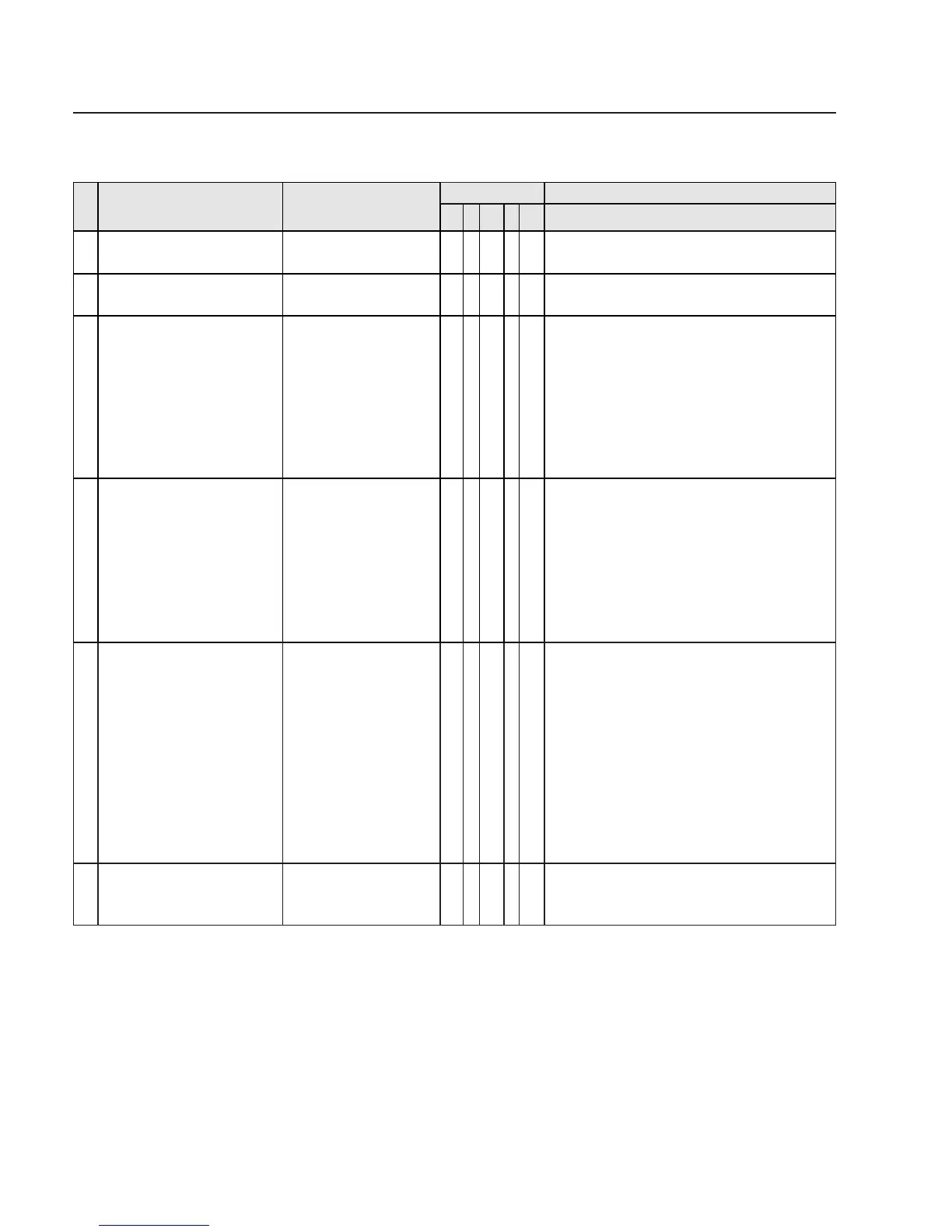

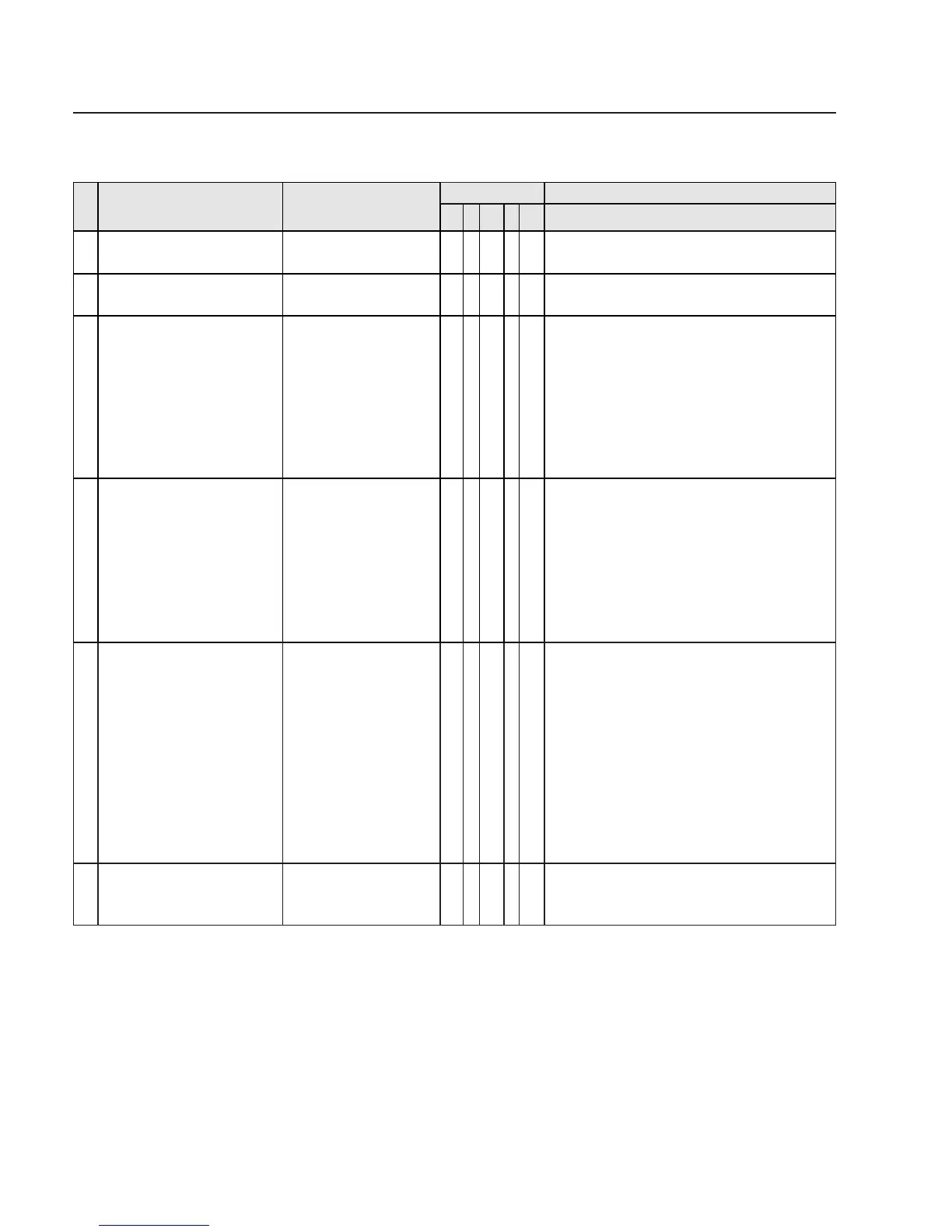

Maintenance Plan

No.

Rotary vane pumps

TRIVAC D 5 E - D 16 E

Measurem./ test quantity

Operating / auxiliary

agents

VE

t 6m a

n-a

Remarks

1 Operate the pump with gas bal-

last for at least 45 minutes.

x Condensed water is thereby removed from the oil.

2 Check the oil level and change

the oil as required.

Oil: N 62 or special and

alternative types of oil,

see Section 3.1

x x Topping up: only after the pump has been switched

off.

3 Check the quality of the oil and

change the oil as required.

visually

chemically

mechanically

x x

x

x

Visually: Normal condition light and transparent, oil

change is required at increasing discolouration.

Chemically: To DIN 51558, when the neutralization

value exceeds 2, then an oil change is required.

Mechanically: When the dynamic viscosity at

25 °C > 240 mPas, then an oil change will be requi-

red.

Disposal of the used oil:

see Section 3.2.1

4 Clean the dirt trap in the intake

and exchange it as required.

Suitable cleaning agent and

compressed air.

x ❏ Clean the dirt trap with a cleaning agent and blow it

clean with compressed air under a suction hood.

❏ Replace the faulty dirt trap.

Use a cleaning agent which complies with national /

international specifications.

Observe the safety regulations which apply to the

cleaning agent used.

Interval

See also Op. Instructions,”Individual Components”

5 Clean the internal demister and

change it as required.

Suitable cleaning agent. x Perform cleaning also in advance of the scheduled

maintenance interval when the noise increases more

and more.

❏ Clean the internal demister with cleaning agent.

❏ Replace a faulty internal demister.

❏ Dispose of the used internal demister as special

waste.

Use a cleaning agent which complies with national /

international specifications.

Observe the safety regulations which apply to the

cleaning agent used.

(parts are contained in Maintenance Kit 1)

(see Section 5)

6 Check the coupling bushings for

damage and wear.

3 Check also in advance of the scheduled maintenance

interval in case of extreme noise.

(parts are contained in Repair Set 1, see Section 5)

4 Maintenance Plan

(Recommendation)

Loading...

Loading...