25

GA 01.600/10.02 - 07/01

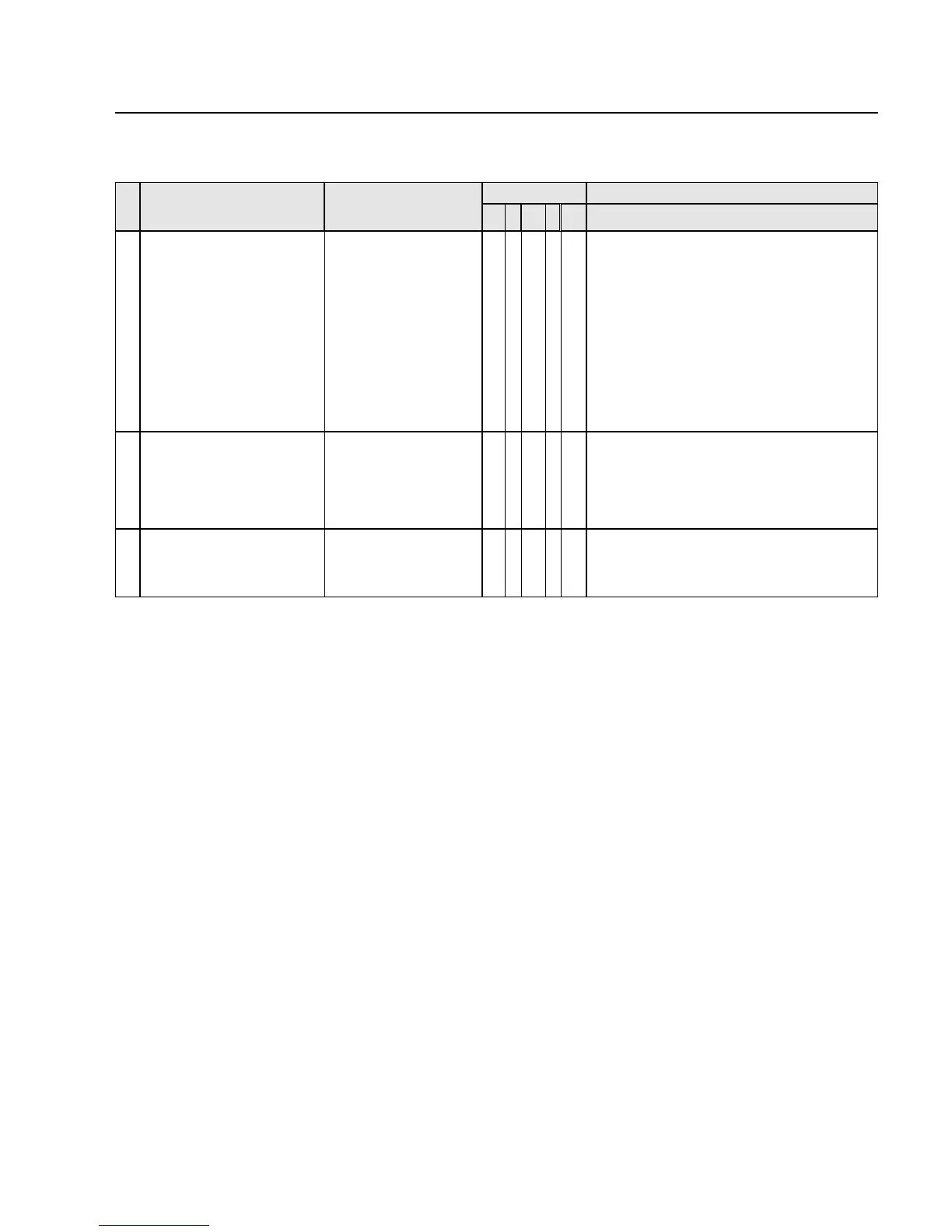

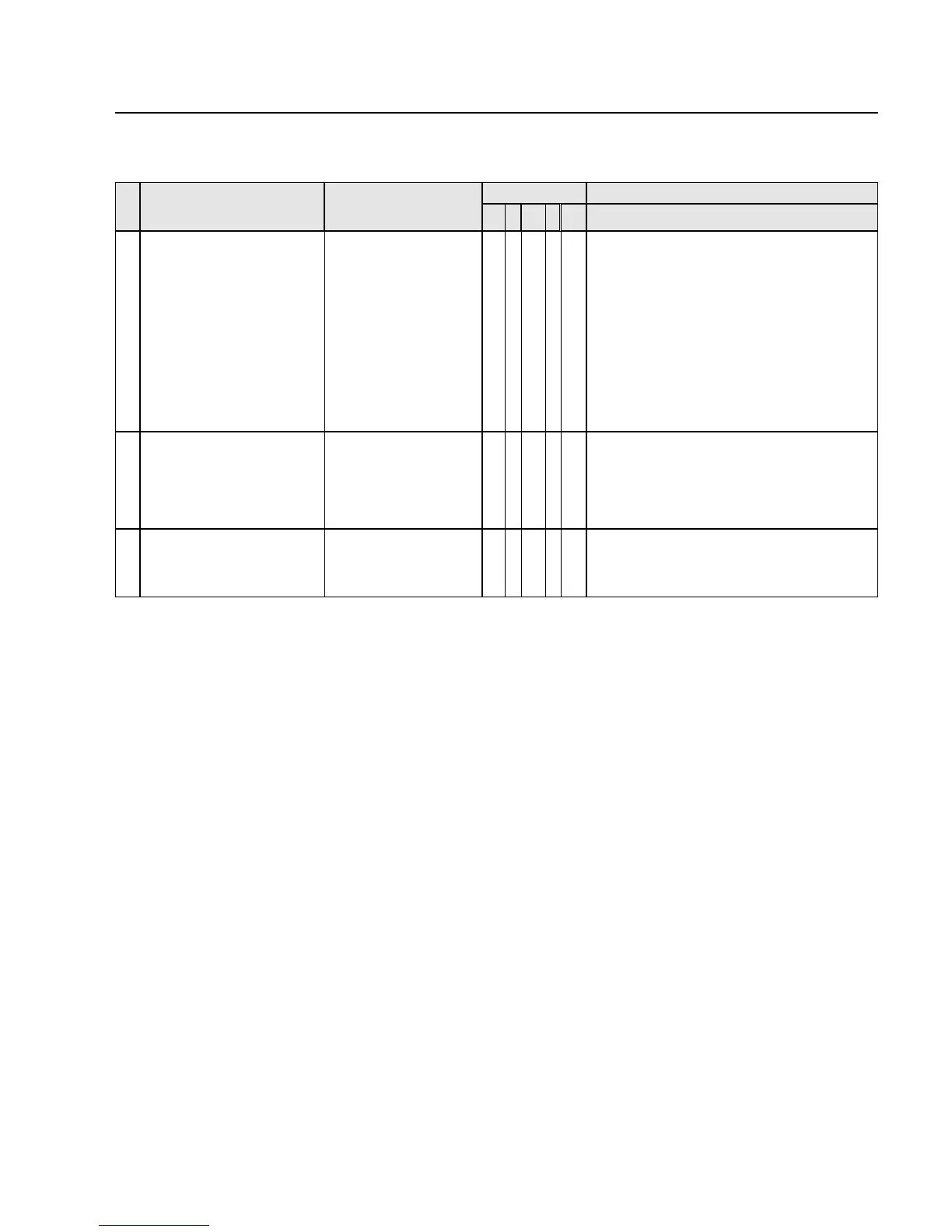

Maintenance Plan

7 Change the oil and

clean the oil level glass.

Oil: N 62 or special and

alternative types of oil

Suitable cleaning agent and

compressed air.

x

No.

Rotary vane pumps

TRIVAC D 5 E - D 16 E

Measurem./ test quantity

Operating / auxiliary

agents

VE t 6m a n-a

RemarksInterval

See also Op. Instructions,”Individual Components”

8 Check the pump’s fan, the motor

fan and the cooling fins of the

motor for dirt, and clean as requi-

red.

Brush and industrial vacuum

cleaner.

x When the pump or the motor is getting too warm clean

before the stated maintenance interval.

Caution: Switch the pump off and secure it against

being started inadvertently (disconnect from the

mains).

Key to the maintenance plan

VE = Perform maintenance before switching the system on

t = Daily maintenance

6m = Maintenance every 6 months

a = Annual maintenance

n-a = Maintenance every n years

Oil change (see Section 3.2)

• First oil change after 100 operating hours.

❏ Clean the oil level glass with a cleaning agent and

blow it clean with compressed air under a suction hood.

Use a cleaning agent which complies with national /

international specifications.

Observe the safety regulations which apply to the

cleaning agent used.

Quantity of oil: see Section 1.4.

Disposal of oil: see page 2.

Every 3 years we recommend servicing of the pump involving the following steps:

• Cleaning

• Checking of individual components

• Exchange of all gaskets

• Functional check.

This check should be performed by the Leybold Service.

9 Full maintenance Maintenance Kit 2. 3 Clean and perform maintenance on the pump as

described in the instructions included with Maintenance

Kit 2 (see Section 5).

Loading...

Loading...