31

GA 01.600/10.02 - 07/01

Troubleshooting

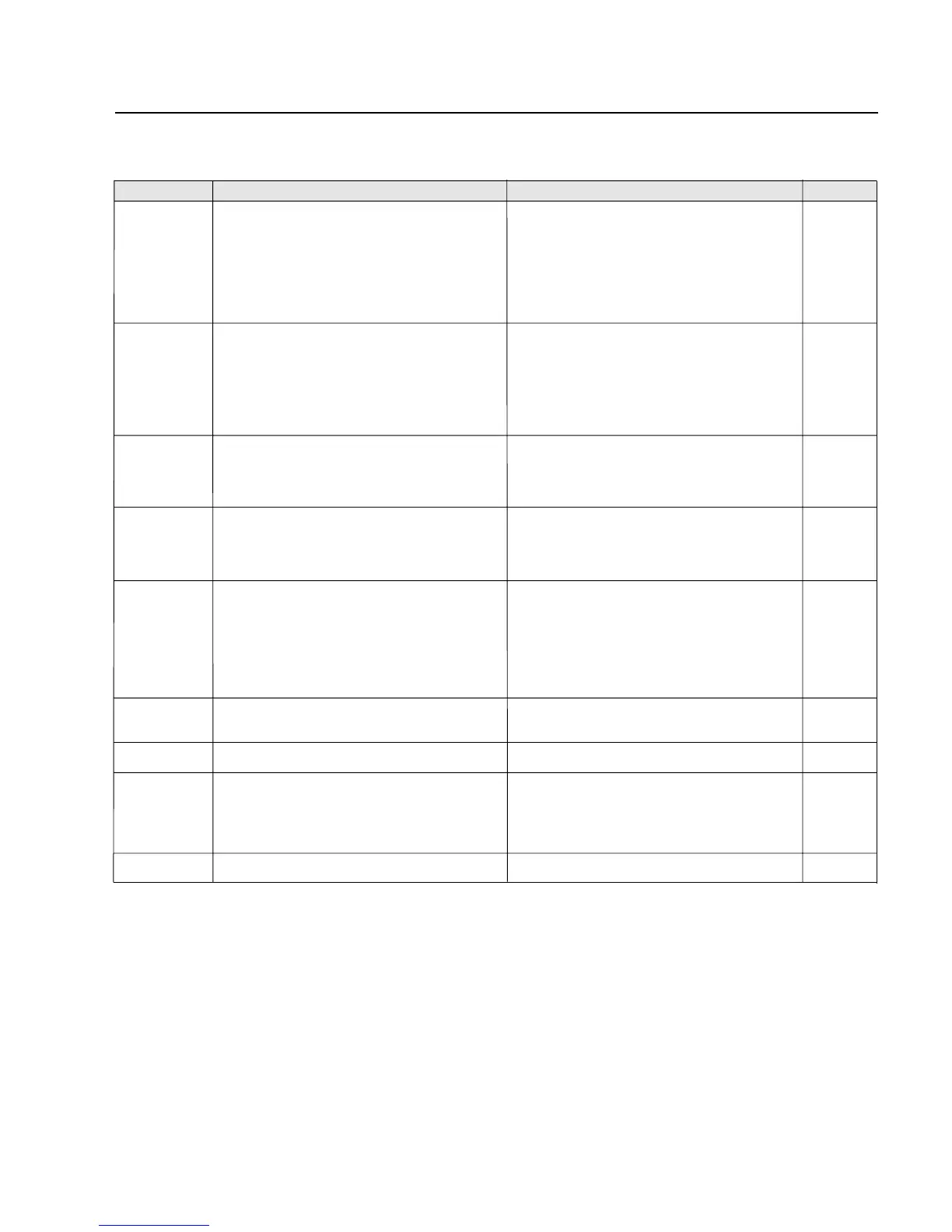

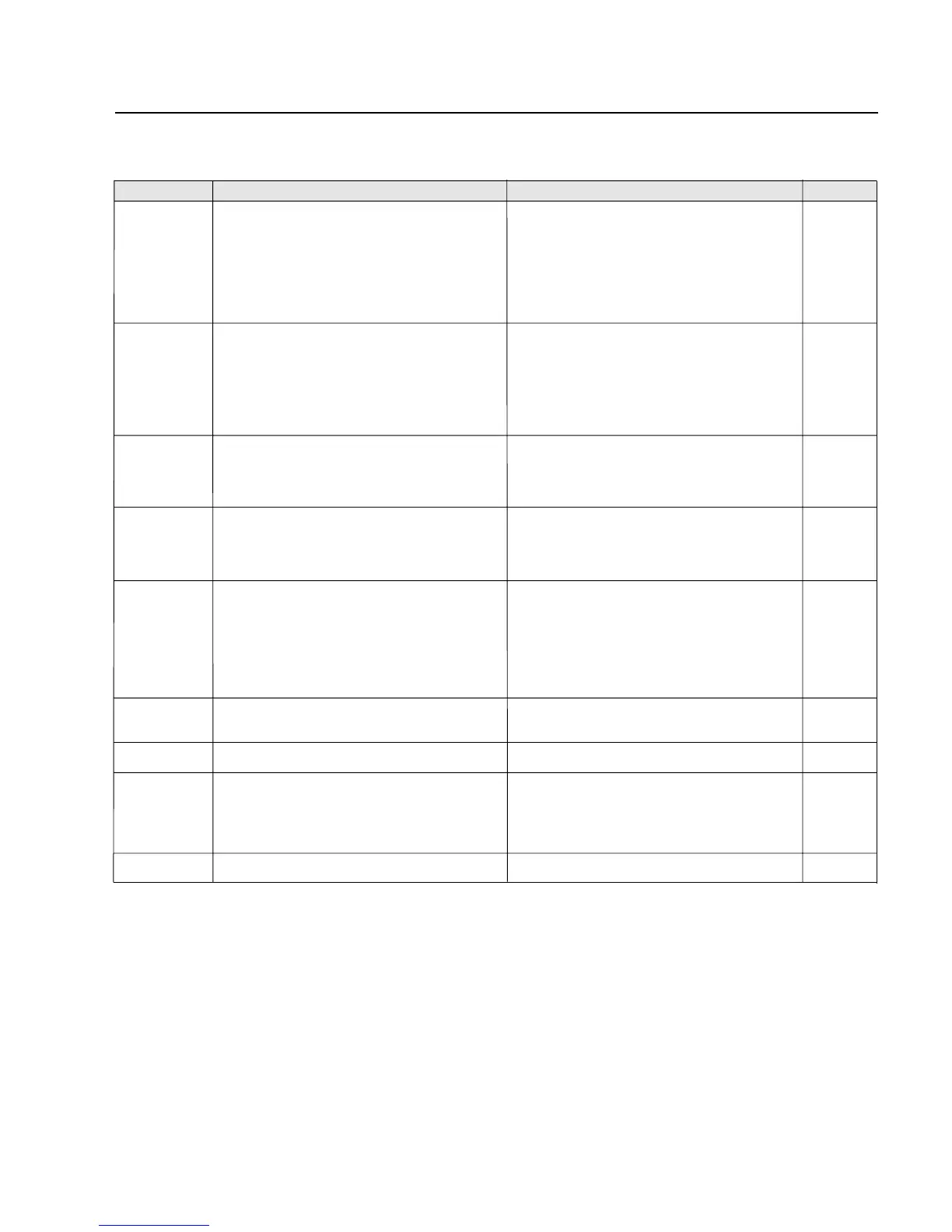

6 Troubleshooting

Fault Possible cause Remedy Repair*

Pump does not start

up.

Pump does not

attain its ultimate

pressure.

Faulty wiring.

Motor protection switch not set correctly.

(three-phase motors only)

Power supply voltage does not match the rating of the motor.

Motor faulty.

Oil temperature less than 12 °C.

Oil is too thick.

Exhaust filter or exhaust line is clogged.

Pump has seized (Sign: blocked pump).

Check the wiring and repair it.

Properly set up the motor protection switch.

Exchange the motor.

Exchange the motor.

Warm up the pump and the oil of the pump or use a different oil.

Change the oil.

Exchange the filter or clean the exhaust line.

Repair the pump.

-

2.3.2

3.5

3.5

2.5.3/3.2

3.2

-

Service

Method of measurement or measuring instrument not suitable.

External leak

1

).

Dirty internal demister.

Faulty exhaust valve.

Unsuitable oil.

Intake line dirty or leaky.

Pump too small.

Use the right method of measurement or measuring instrument.

Measure the pressure directly at the intake port of the pump.

Repair the pump.

Perform maintenance.

Repair the valve.

Change the oil (possibly degas it).

Clean or exchange the intake line.

Check process data, possibly change the pump.

-

Service

Main.kit1/2.3.5

Rep.-Set 2

3.2

-

-

Pumping speed of

the pump is too low.

Dirt trap in the intake line is clogged.

Clogged exhaust filter.

Connection lines too narrow or too long.

Clean the dirt trap.

Preventive action: install a dust filter in the intake line.

Exchange the filter element.

Use sufficiently wide and short intake lines.

3.3

-

2.2

Pump gets hotter

than previously

observed.

Supply of cooling air is obstructed.

Ambient temperature is too high.

Process gas is too hot.

Not enough oil.

Unsuitable oil.

Oil circulation is obstructed.

Clogged exhaust filter or exhaust line.

Exhaust valve faulty.

Deviating mains supply voltage.

Properly install the pump.

Properly install the pump.

Change the process.

Fill in oil.

Change the oil.

Clean or repair the oil channels.

Change the exhaust filter, clean the exhaust line.

Repair the valve.

Check power supply rating of the motor and the mains supply.

Oil is turbid. Condensation. Degas the oil or change the oil and clean the pump.

Preventive action: open the gas ballast valve or fit a separator.

2.5.2/3.2

2.1

2.1/2.5.3

-

Service

-

Rep. Set 2

The pump is extre-

mely loud.

Oil level is much too low (oil is no longer visible).

Intake pressure is too high.

Clogged internal demister.

Coupling bushings worn out.

Damaged vanes or bearings.

Faulty motor bearing.

Top up some oil.

Reduce the intake pressure.

Clean or replace the internal demister.

Replace the coupling bushings.

Repair the pump.

Exchange the motor bearing.

3.2

-

3.4/Maint.Kit 1

Rep. Set 1

Service

Service

After switching the

pump off the pressu-

re in the system

increases to fast.

System has a leak.

Faulty tandem valve.

Inner shaft seal is faulty.

Faulty exhaust or bypass valve.

Check the system.

Repair the valve.

Exchange the shaft seal.

Repair the valve(s).

-

Rep. Set 3

Rep. Set 3

Rep. Set 2

Oil in the intake line

or the vacuum

chamber.

Oil coming from the system.

Blocked tandem valve.

Check the system.

Clean the valve or repair it.

-

Rep. Set 3

1

) Bubble test: The warm pump with degassed oil is running without gas ballast with the intake blanked off. The exhaust line is lead into a vessel containing water. If an

evenly spaced row of bubbles appears, then the pump has developed an external leak.

Oil leak at the side

of the motor

Outer shaft seal damaged or worn out.

Exchange the shaft seal.

Rep. Set 1

*Descriptions relating to the repairs or maintenance work have been included with the respective maintenance kits or repair sets. For ordering information please refer

to Section 5.1.

Loading...

Loading...