5 Installation

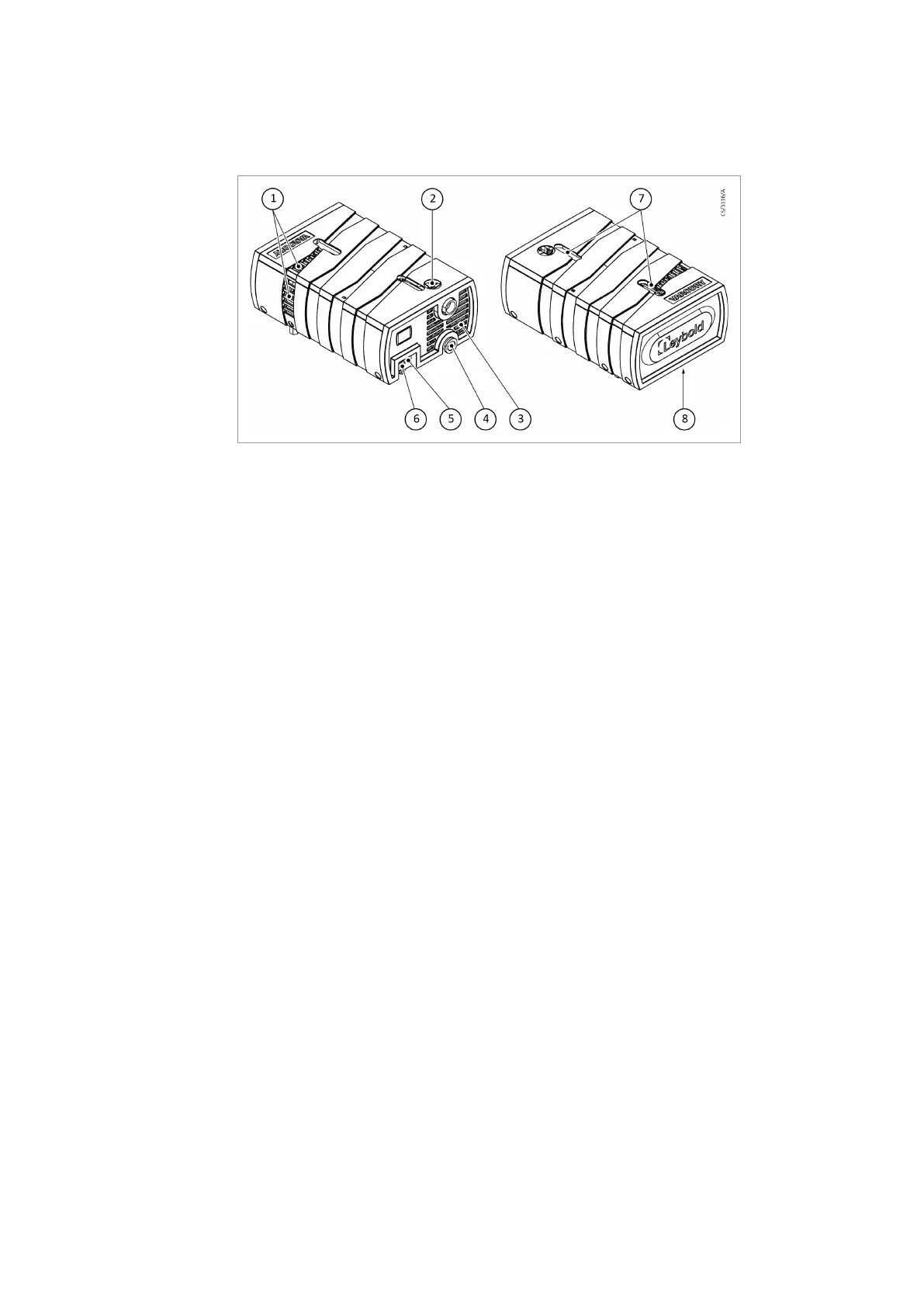

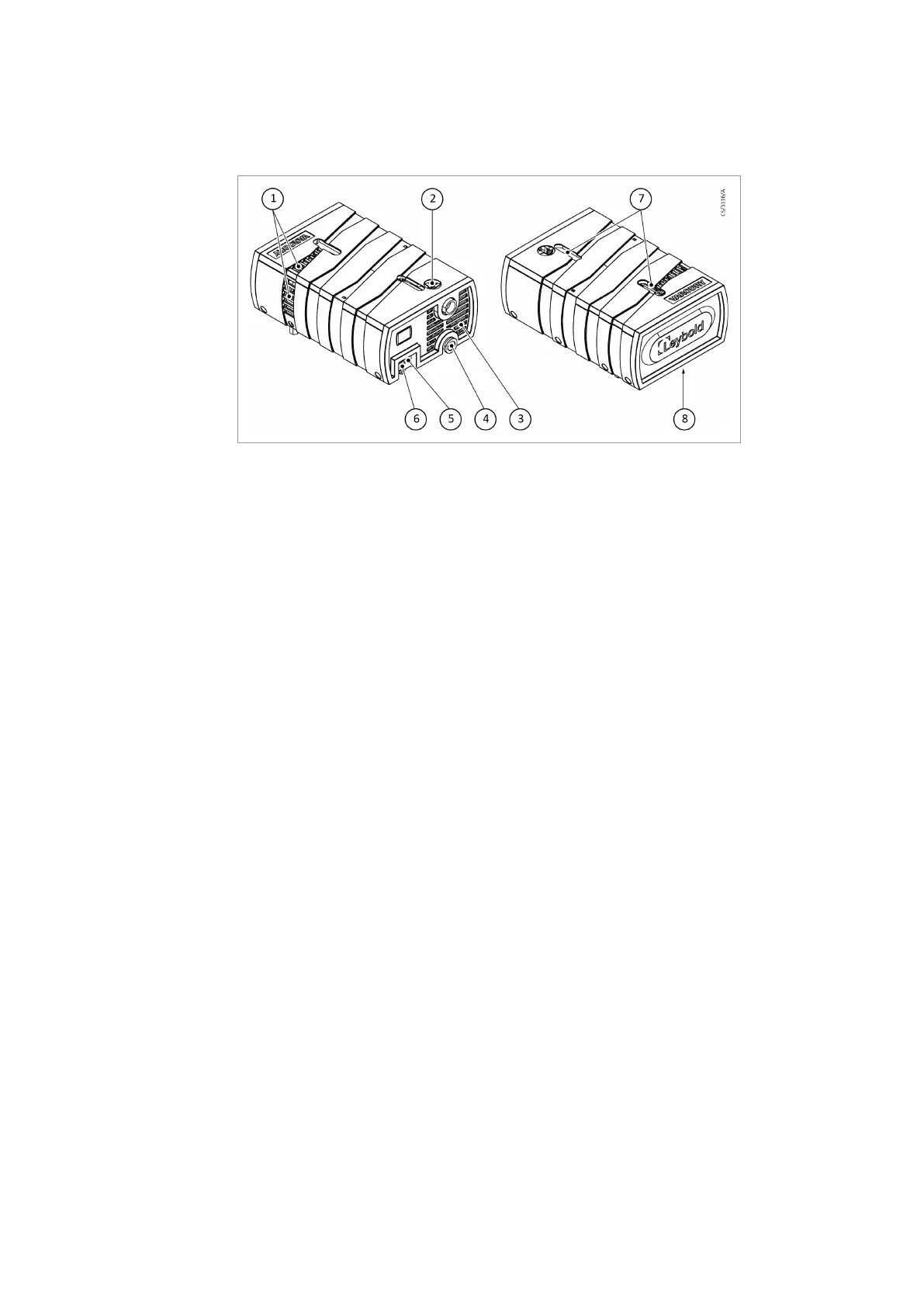

Figure 3.

Connections and controls

1.

Cooling air - out

2.

Inlet ange

3.

Cooling air - out

4.

Exhaust ange

5.

Purge gas port (optional)

6.

Electrical feedthroughs

7.

Lifting eye

8.

Cooling air - in

1.

Cooling air - out

2.

Inlet ange

3.

Cooling air - out

4.

Exhaust ange

5.

Purge gas port (optional)

6.

Electrical feedthroughs

7.

Lifting eye

8.

Cooling air - in

5.1 Placement

The cooling air intake and outlets must not have a blockage to prevent insufcient cooling

of the pump. Figure: Connections and controls on page 13.

5.2 Conforming Use

The VARODRY range is designed for use in light and medium industrial applications. The

pumps are capable to handle small amounts of dust and liquids however the use of inlet

lters or liquid traps is recommended in such cases. They are not hermetically sealed and

will release small amounts of pumped gases to ambient even if the exhaust port is

connected to an exhaust pipework. They are suitable for pumping water steam or other

vapors within the limits of the vapor tolerance. The pump can be used both continuously

at a suction pressure range of 0.01 mbar to 1050 mbar as well as for cyclic pump

operations within this pressure range.

5.2.1 Non-conforming Use

The VARODRY is not suited for pumping of:

▪ Radioactive substances

▪ Explosive substances

▪ Ignitable gas mixtures

▪ Pyrophoric gases

▪ Liquids

▪ Media in signicant amounts condensing in the pump (Except from water)

▪ Solids

▪ Corrosive gases

▪ Oxidative substances with the exception of £ 21% oxygen in the air

▪ Toxic gases

13

300766038_002 - © Leybold

Installation

Loading...

Loading...