31

ENGLISH

The amount of Refrigerant

The calculation of the additional charge should take into account the

length of pipe and CF(correction Factor) value of indoor unit.

Include only for

Heat Recovery

system

Total liquid pipe : Ø 25.4 mm (1.0 inch)

Additional charge(kg)

Total liquid pipe : Ø 22.2 mm (7/8 inch)

Total liquid pipe : Ø 19.05 mm (3/4 inch)

Total liquid pipe : Ø 15.88 mm (5/8 inch)

Total liquid pipe : Ø 12.7 mm (1/2 inch)

Total liquid pipe : Ø 9.52 mm (3/8 inch)

Total liquid pipe : Ø 6.35 mm (1/4 inch)

Number of installed HR units

CF value of indoor unit

=

+

+

+

+

+

+

+

× 0.480 kg/m (0.323 lbs/ft)

× 0.354 kg/m (0.238 lbs/ft)

× 0.266 kg/m (0.179 lbs/ft)

× 0.173 kg/m (0.116 lbs/ft)

× 0.118 kg/m (0.079 lbs/ft)

× 0.061 kg/m (0.041 lbs/ft)

× 0.022 kg/m (0.015 lbs/ft)

× 0.5 kg/EA (1.1 lbs/EA)

Amount refrigerant of Indoor units

Example) 4Way Ceiling Cassette 14.5 kW -1ea, Ceiling concealed

Duct 7.3 kW-2ea,

Wall Mounted 2.3 kW-4ea

CF = [0.64 kg (1.411 lbs)×1EA] + [0.26 kg (0.573

lbs)×2EA] + [0.26 kg (0.529 lbs)×4EA]

= 2.12 kg (4.67 lbs)

WARNING

• Regulation for refrigerant leakage

: the amount of refrigerant leakage should satisfy the following

equation for human safety.

If the above equation can not be satisfied, then follow the

following steps.

• Selection of air conditioning system: select one of the next

- Installation of effective opening part

- Reconfirmation of Outdoor Unit capacity and piping length

- Reduction of the amount of refrigerant

- Installation of 2 or more security device (alarm for gas leakage)

• Change Indoor Unit type

:

installation position should be over 2 m (6.6 ft) from the floor (Wall

mounted type ’ Cassette type)

• Adoption of ventilation system

: choose ordinary ventilation system or building ventilation

system

• Limitation in piping work

: Prepare for earthquake and thermal stress

!

Volume of the room at which Indoor Unit of

the least capacity is installed

Total amount of refrigerant in the system

≤0.44 kg/m

3

(0.028 lbs/ft

3

)

Attach the additional refrigerant table of IDU.

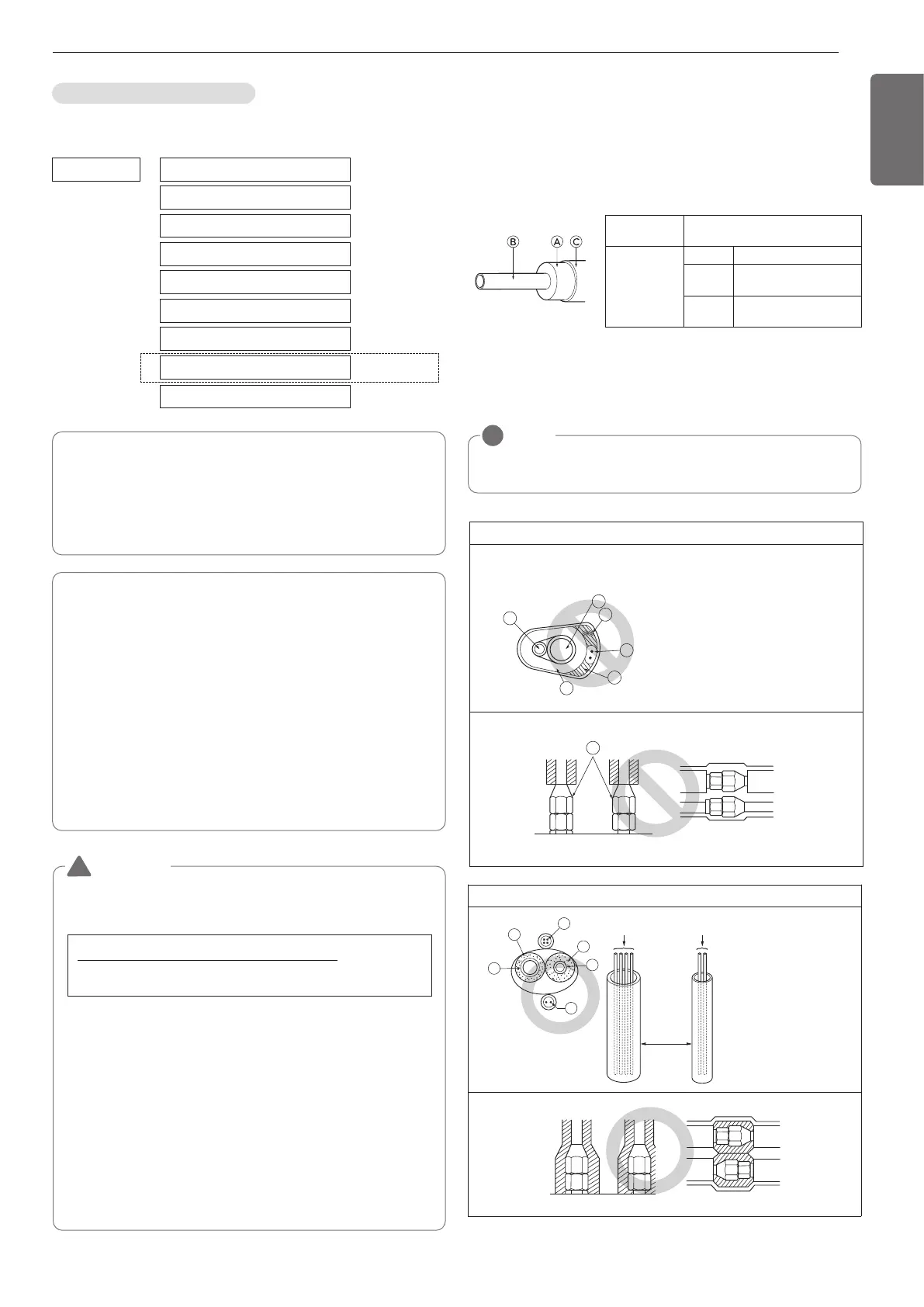

Bad example

• Do not insulate gas or low pressure pipe and liquid or

highpressure pipe together.

• Be sure to fully insulate connecting portion.

Ⓐ

These parts are not insulated.

Ⓐ Liquid pipe

Ⓑ Gas pipe

ⓒ Power lines

ⓓ

Finishing tape

ⓔ

Insulating material

ⓕ

Communication lines

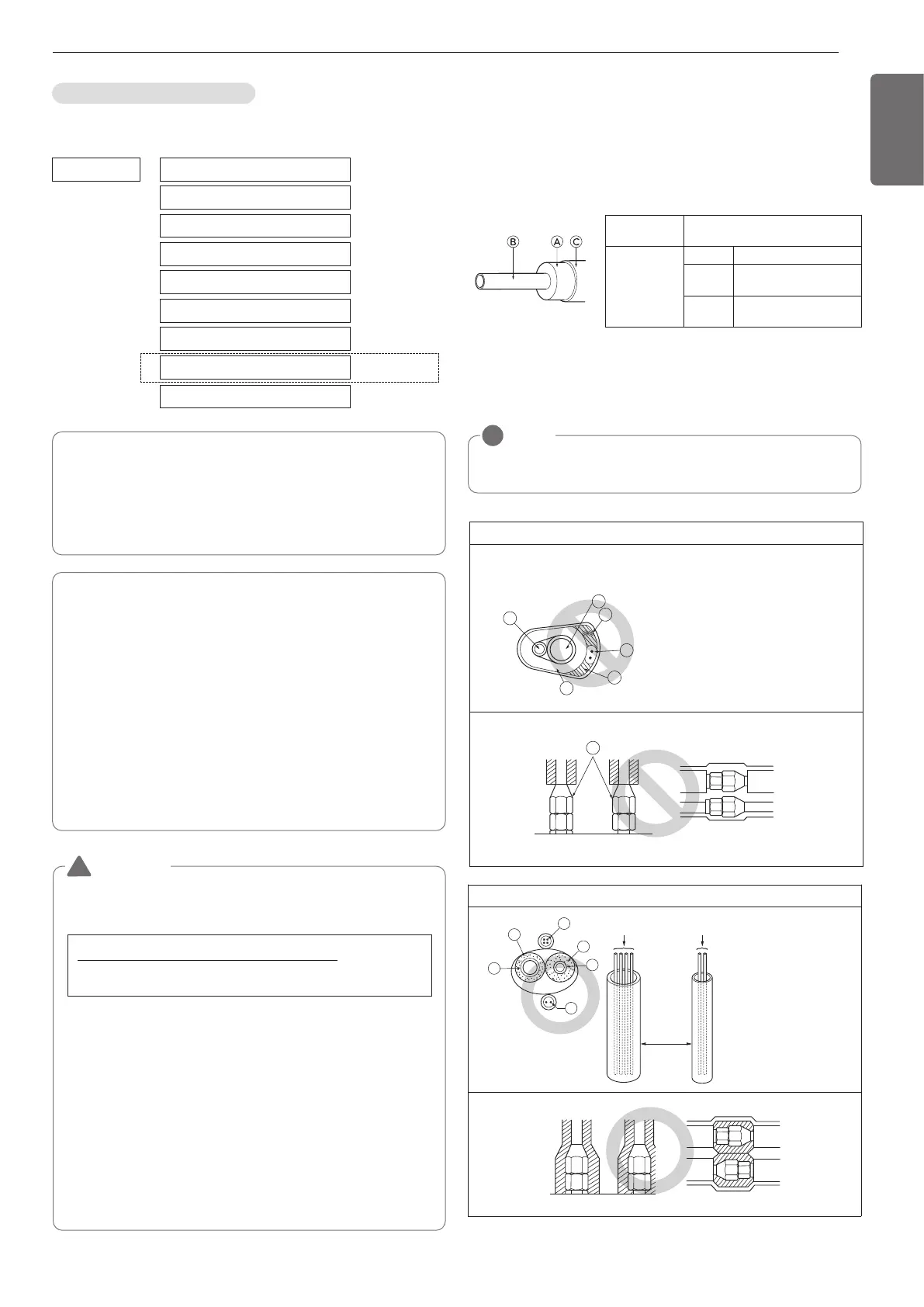

Be sure to give insulation work to refrigerant piping by covering liquid

pipe and gas pipe separately with enough thickness heat-resistant

polyethylene, so that no gap is observed in the joint between indoor

unit and insulating material, and insulating materials themselves. When

insulation work is insufficient, there is a possibility of condensation

drip, etc. Pay special attention to insulation work to ceiling plenum.

Ⓐ Heat insulation material

Ⓑ Pipe

Ⓒ Outer covering(Wind the connection part and cutting part of heat

insulation material with a finishing tape.)

Heat insulation

material

Adhesive + Heat - resistant

polyethylene foam + Adhesive tape

Outer

covering

Indoor Vinyl tape

Floor

exposed

Water-proof hemp cloth +

Bronze asphalt

Outdoor

Water-proof hemp cloth +

Zinc plate + Oily paint

NOTE

!

When using polyethylene cover as covering material, asphalt

roofing shall not be required.

Thermal insulation of refrigerant piping

Good example

Ⓐ Liquid pipe

Ⓑ Gas pipe

ⓒ Power lines

ⓓ

Insulating material

ⓔ

Communication lines

Loading...

Loading...