13

ENGLISH

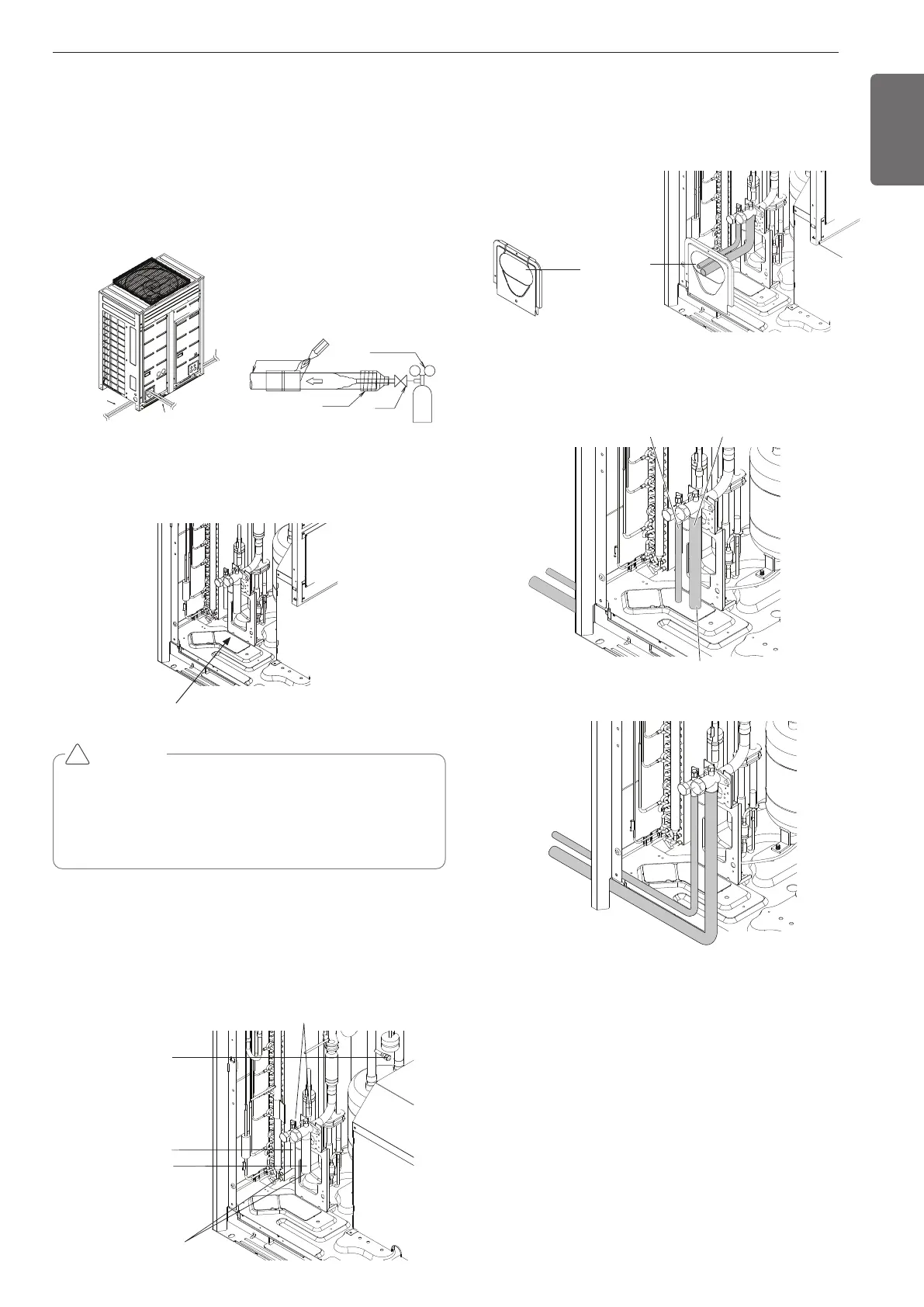

- Pipe connections can be done on the front side or on the side accord-

ing to the installation environments.

- Be sure to let 0.2kgf/cm

2

Nitrogen flow in the pipe when welding.

- If Nitrogen was not flown during welding, many oxidized membranes

may form inside the pipe and disturb the normal operations of valves

and condensers.

CAUTION

• Do not give damage to the pipe/base during the Knock Out

work.

• Proceed to pipe work after removing burr after Knock Out work.

• Perform sleeve work to prevent damage to the wire when con-

necting wires using knock Outs.

!

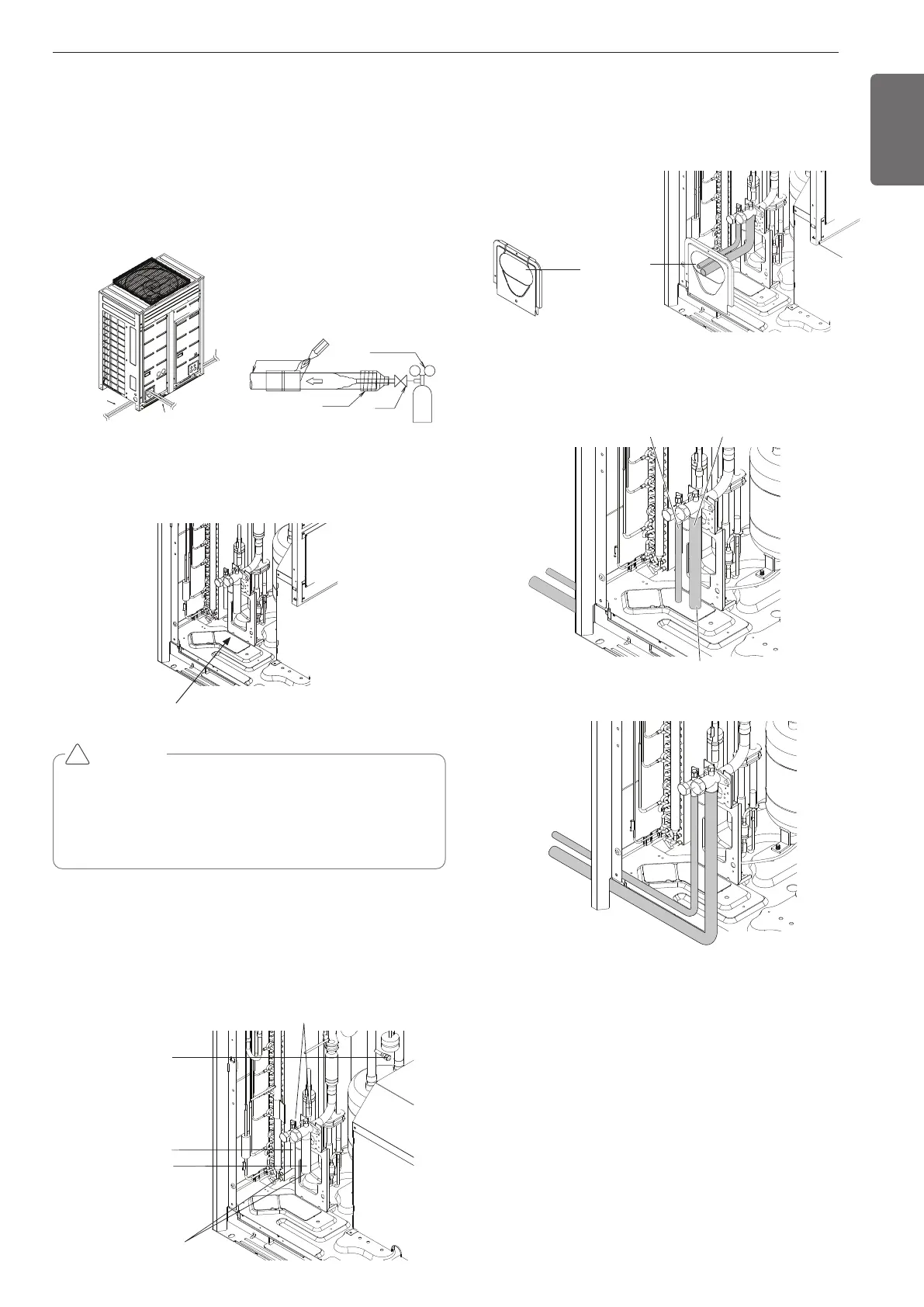

Remove leakage prevention cap

• Remove the leakage prevention cap attached to the outdoor unit

service valve before pipe work.

• Proceed the leakage prevention cap removal as follows:

- Verify whether the liquid/gas pipes are locked.

- Extract remaining refrigerant or air inside using the service port.

- Remove the leakage prevention cap

Method of drawing out pipes on the bottom side

- Drawing out common pipe through side panel

Left Side Pipe

Draw Out

Front Pipe Draw Out

Right Side Pipe

Draw Out

R

efrigerant Pipe

R

egulator

N

itrogen

Taping

V

alve

NitrogenNitrogen

D

irection Direction

Nitrogen

D

irection

Removal Area for Liquid/Gas pipe

bottom side connections.

Gas pipe

Liquid pipe

Service Port

Refrigerant Charging Port

Leakage Prevention Cap

Pipe Knock Out for

Liquid/Gas pipes

Liquid pipe Gas pipe

Remove only liquid/gas pipe Knock out

Liquid pipe Gas pipe

Remove only liquid/gas pipe Knock out

P

ipe Drawing Out during Single / Series connection

Method of drawing out pipes on the front side

- Proceed with the pipe work as shown in the below figure for front

side pipe drawing out.

Preparation Work

- Use Knock Outs of Base Pan of the outdoor unit for Left/Right or Bot-

tom pipe drawing outs.

PIPE CONNECTIONS BETWEEN

INDOOR AND OUTDOOR UNIT

Loading...

Loading...