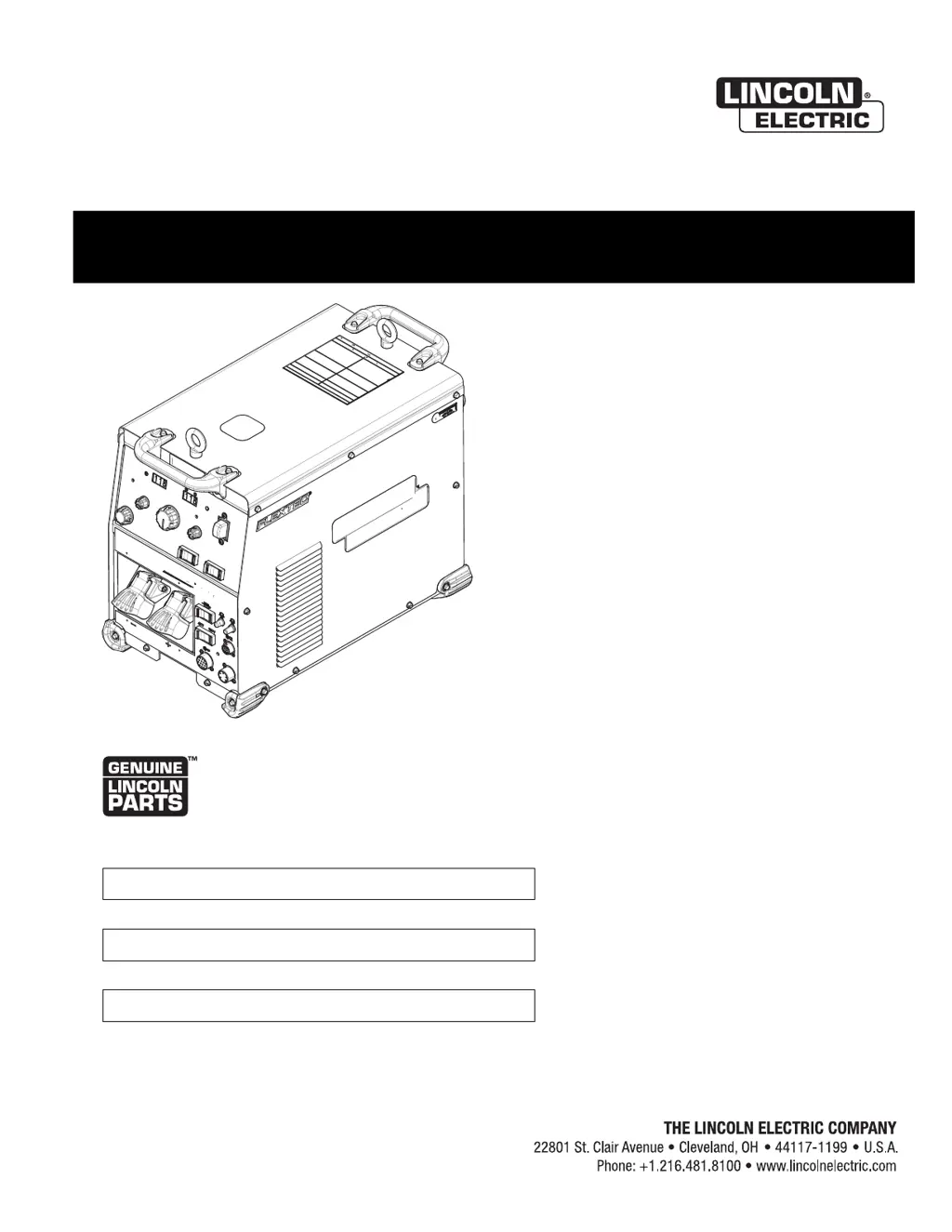

What to do if my Lincoln Electric Flextec 650x won’t weld?

- RRichard DunnAug 17, 2025

If your Lincoln Electric Welding System won't weld, and the displays show an Err ###, check the fault section for corrective action. If the thermal LED is lit, refer to the thermal section. Also, if the output terminals are in remote control, switch to "ON" and check for output voltage. If output voltage is now present, verify the remote control connection and operation are correct.