What does Error Code #715 indicate on a Lincoln Electric Flextec 650x Welding System?

- CcjacksonSep 12, 2025

If your Lincoln Electric Welding System displays Error Code #715, the machine needs to be turned off and back on to reset.

What does Error Code #715 indicate on a Lincoln Electric Flextec 650x Welding System?

If your Lincoln Electric Welding System displays Error Code #715, the machine needs to be turned off and back on to reset.

How do I fix Error Code #719 on my Lincoln Electric Flextec 650x Welding System?

If your Lincoln Electric Welding System displays Error Code #719, the machine needs to be turned off and back on to reset.

| Brand | Lincoln Electric |

|---|---|

| Model | Flextec 650x |

| Category | Welding System |

| Language | English |

Inspect packaging and equipment for damage upon receipt.

Follow manual and safety precautions; keep head out of fumes; ensure ventilation.

Wear proper eye, ear, and body protection for welding.

Avoid welding hazardous materials/containers; use ventilation for painted parts.

Warnings about chemicals known to cause cancer and birth defects.

Protect yourself and others from arc welding dangers; consult doctor if pacemaker user.

Specific safety guidelines for operating engine-powered equipment.

Understand and minimize exposure to EMF fields during welding.

Take precautions to prevent electric shock from welding equipment.

Protect eyes and skin from arc rays using proper shielding.

Ensure adequate ventilation and avoid breathing hazardous fumes and gases.

Remove fire hazards; prevent sparks from causing fires or explosions.

Handle compressed gas cylinders carefully to prevent explosions.

Follow codes for installing and grounding electrically powered equipment.

Details on input voltage, current, idle power, and power factor.

Output ratings (Amps, Volts) for various welding processes and duty cycles.

Guidelines for selecting appropriate input wire and fuse sizes.

Dimensions (Height, Width, Depth) and Weight of the Flextec 650x.

Operating and storage temperature limits for the equipment.

Input voltage ranges for VRD Enabled and Disabled modes.

Precautions for qualified personnel, power off, grounding.

Information on the VRD feature and its function.

Guidelines for selecting a suitable operating location and ensuring proper ventilation.

Instructions for safe handling and placement of the machine.

Guidelines for operating the machine in outdoor and environmental conditions.

Procedures for connecting input power and ensuring proper machine grounding.

Advice on protecting equipment from high frequency interference.

Output ratings at elevated temperatures (55°C).

Steps for connecting input power supply and selecting voltage.

Guidance on selecting appropriate input fuses and supply wire sizes.

Details of pin assignments for 12-pin accessory, 5-pin, and 14-pin wire feeder connectors.

Connecting electrode and work cables, polarity, cable routing.

Recommendations for using Lincoln control cables and their length.

Instructions for paralleling Flextec® 650x units for increased output.

Diagram and control settings for connecting LF-72 and LF-74 wire feeders.

Diagram and control settings for LN-10 and DH-10 wire feeders.

Guide to setting DIP switches for LN-10 and DH-10 controls.

Diagrams and settings for LN-25 Pro/Pipe, Activ8 feeders.

Diagram and settings for LN-25 Pro Dual Power feeder.

Diagram and control settings for connecting the LN-7 wire feeder.

Diagrams and control settings for connecting LN-8 and LN-9 wire feeders.

Diagrams and settings for NA-3, NA-5 wire feeders.

Diagram and control settings for connecting the LT-7 tractor.

Warnings about electrical shock, fumes, fire, and arc rays during operation.

Explanation of symbols used on the machine and in the manual.

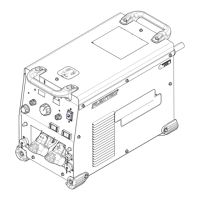

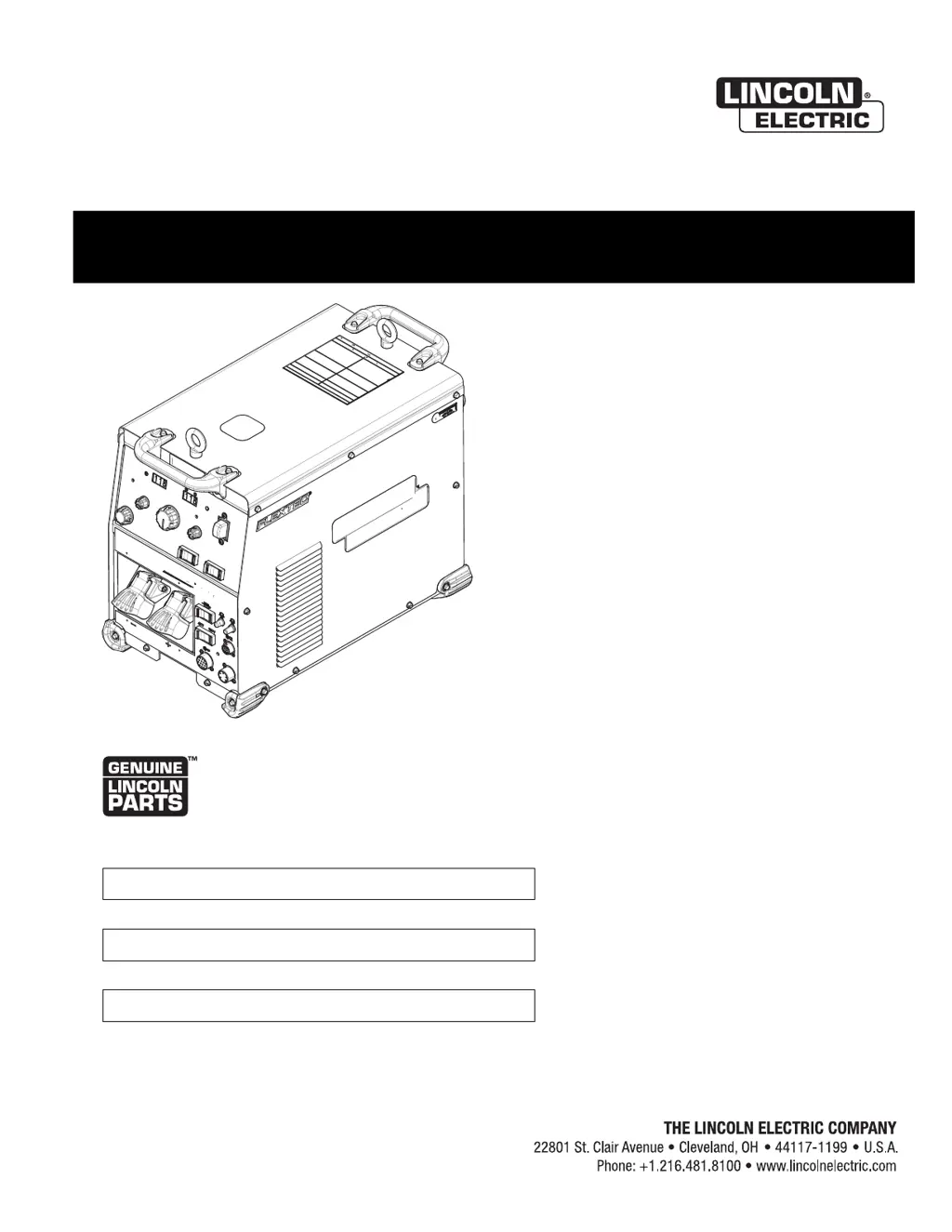

Overview of the Flextec 650x, its features, and power capabilities.

Detailed explanation of each control and indicator on the machine's front panel.

Explanation of the input power cord hole, access panel, reconnect, and auxiliary power features.

How to set internal dip switches for VRD, Multi-Weld, and calibration.

What happens when power is applied to the machine.

Guidelines for selecting weld modes and procedures.

Explanation of controls, meters, and indicator lights for operation.

Operation details, controls, and meters for GTAW mode.

Operation details, controls, and meters for CV-Gas welding.

Operation details, controls, and meters for CV-Innershield welding.

Operation details, controls, and meters for CV-SAW welding.

Operation details for ArcLink mode, controlled by wire feeder.

Explanation of CrossLinc communication for remote voltage control.

Safety precautions for performing maintenance on the equipment.

Inspecting internal components for signs of damage or overheating.

Performing daily checks on VRD functionality and periodic cleaning.

Understanding thermal protection and performing periodic cleaning.

Step-by-step guide for calibrating the machine's current and voltage output.

Instructions on how to use the guide to identify and resolve issues.

Common problems, possible causes, and recommended actions for the machine.

Information on status LEDs and troubleshooting using fault codes.

Detailed wiring diagram for the Flextec 650x with code 12596.

Visual representation of the machine's dimensions and layout.

Details Lincoln Electric's policy on providing advice and information on products.

Loading...

Loading...