LT360 Precision Turntable

User Manual

LT360 Precision Turntable

User Manual

35

■ Pulse Input

This BNC connector provides a means to step the turntable via a TTL pulse.

Each pulse will cause the turntable to rotate by the current step size, and in

the directioon of either CCW or CW.

The pulse width should be a minimum of 10uSec. Triggering based on the

Rising or Falling edge can be selected.

Pulses are only accepted when the platter is not already in motion. If the

platter is already rotating, the pulse will be ignored.

The Pulse Input can be enabled or disabled, either by using the Win32

application program or through USB or RS-232 commands.

■ Analog Input

This BNC connector provides a means to control the location of the platter

by analog voltage. The Analog Input can be enabled or disabled, either by

using the Win32 application program or through USB or RS-232 commands.

Note: This input must be disabled if not in use, otherwise it will override all

other control methods.

The scale factor is 10mV/deg, and the resolution of the LT360 is 0.1 degree.

Therefore, the step size and/or resolution of the analog voltage should be at

least 1mV. The actual input circuitry is differential to help reject ground

noise. The voltage range can either Unipolar (0..+3.600) or Bipolar

(0..±1.800) as selected in the software or by commands.

54

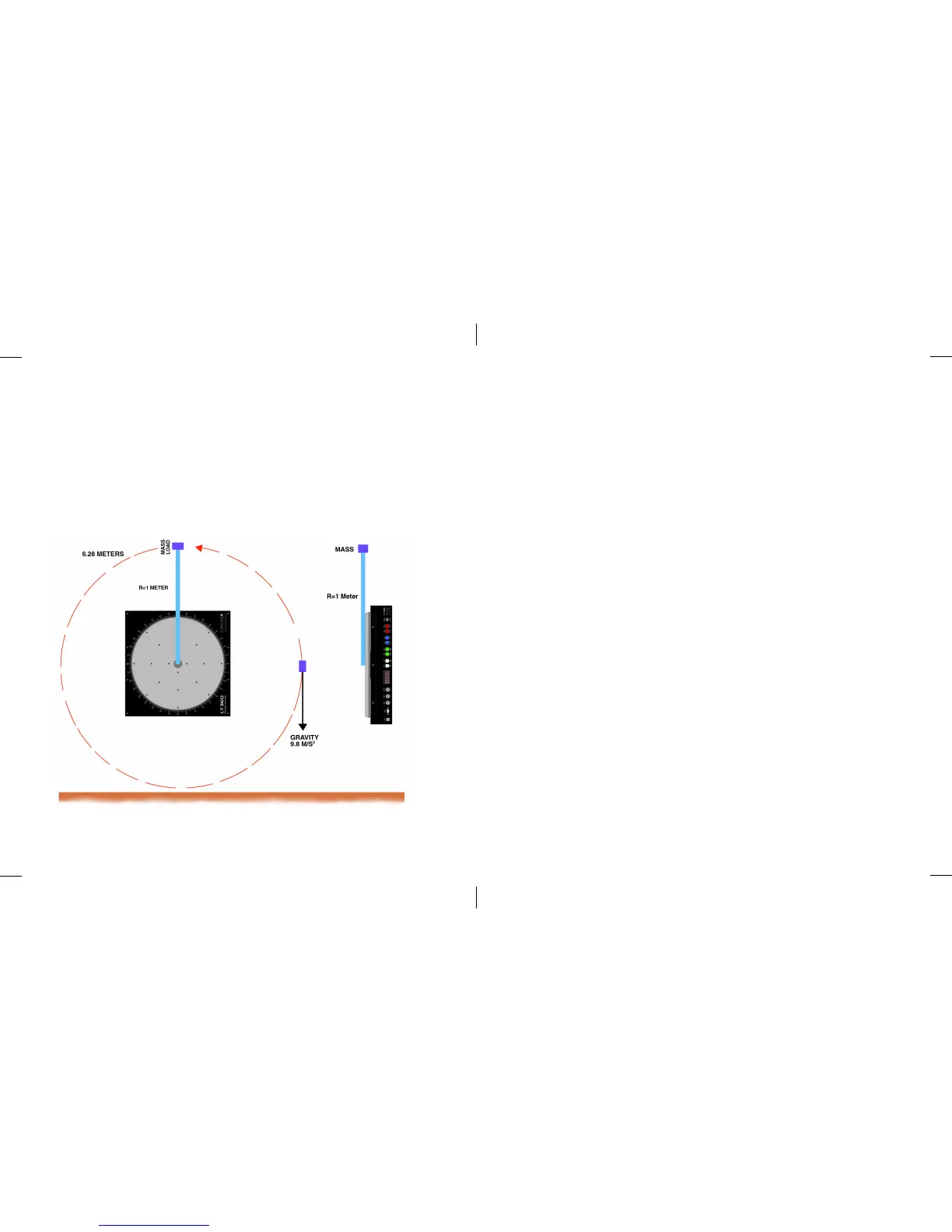

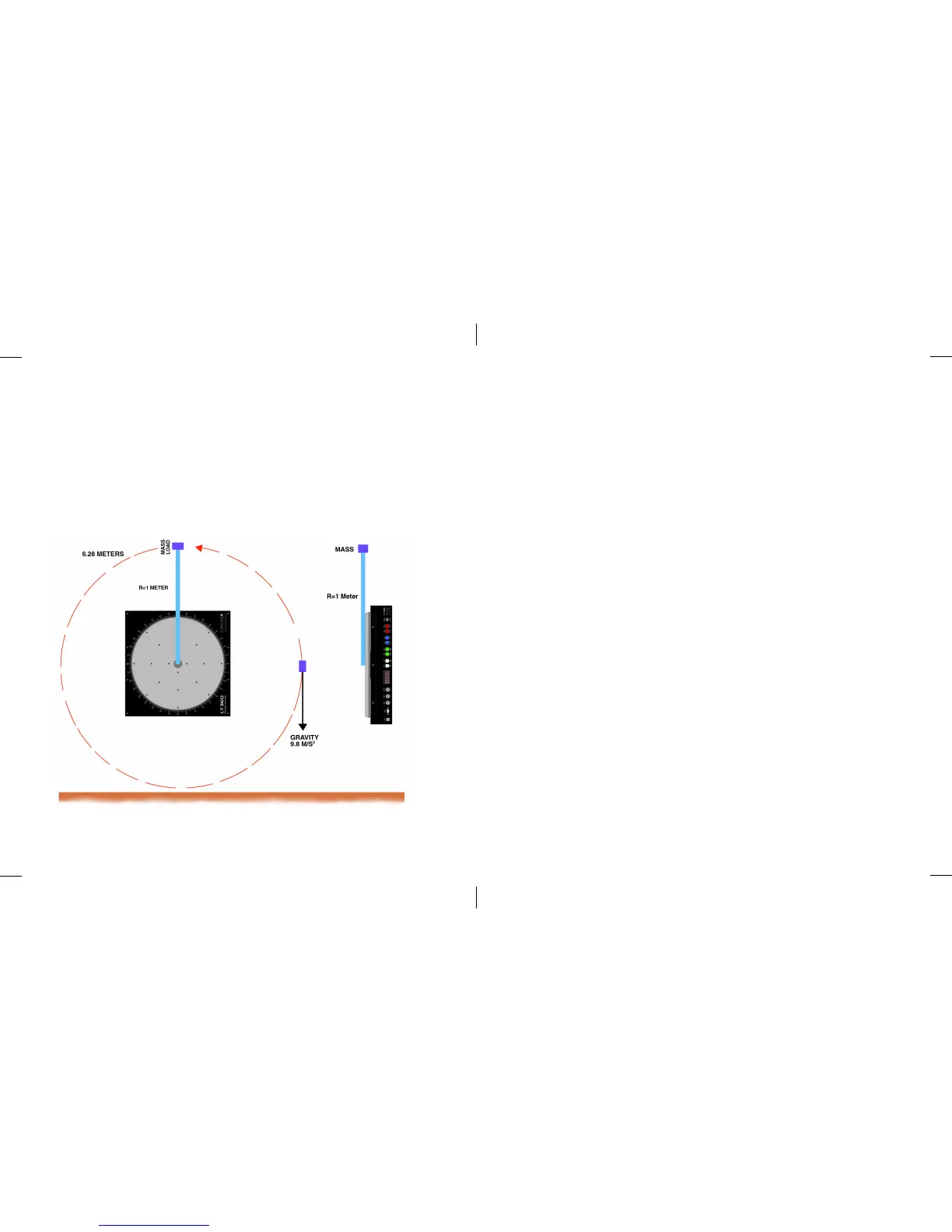

6.5 Vertical Torque Capability

The case of vertical torque is shown in the pictorials below. In this case the

LT360 is located vertically relative to the ground surface. In this configura-

tion the mass load is being acted upon by the acceleration of gravity. The

acceleration of gravity is 9.8M/S

2

, generally much larger than the rotational

acceleration of the LT360. For this reason the mass load capability will be

greatly reduced.

Loading...

Loading...