Installation of the PT-Series

Truck Pump

The mechanical installation of the PT-Series pump is a simple

matter. A rotation arrow is located on the side of the pump.

Examine the PTO and determine the direction of its rotation

before installing the pump. The PT-Series pump will match

either PTO rotation. Connect the drive shaft to the pump shaft

that turns the pump in the direction of the arrow.

The PTO SELECTION is important. For maximum

performance , the pump requires a PTO with an average

output speed of 500 to 700 RPM. In addition, the truck engine

must be operating at the appropriate RPM to maintain oil

pressure, water circulation, and the electrical system.

THE DRIVESHAFT that connects the pump to the PTO

should be of the “splined” or slip type. This type of driveshaft

permits the shaft to adjust for PTO movement and twisting

of the truck frame. A fixed driveshaft will transfer the

forces directly to the pump and PTO and shorten the life

of both considerably. The yokes of the driveshaft universal

joints must be positioned as shown in Figure 1. Improper

positioning will cause premature wear and potentially

destroy the bearings in the pump and PTO.

INLET PIPING should be as short as possible and at

least the minimum diameter specified for the model with

few restrictions so that the pressure drop is limited.

The outlet piping should include the following:

1. A pressure gauge should be installed in the pump

outlet or near it. A pressure gauge is necessary to

determine the efficiency of your pumping system.

2. If a meter with an air eliminator is installed, never pipe

the eliminator directly into the pump inlet piping or

into the liquid part of the system at any point (refer to

the meter installation manual).

3. The discharge piping should be at least the same size

as the meter piping.

Power Take-Off Drive Systems

Proper pump operation and long life is directly dependent

upon a good drive system. Many truck pumps utilize a power

train consisting of shafts and universal joints located between

the power take-off shaft of the truck engine and the pump.

There are several basic principles that should be followed

in designing a PTO drive. To produce a workable power

train that results in long pump life and reduced drive wear,

these principles SHOULD NOT be violated.

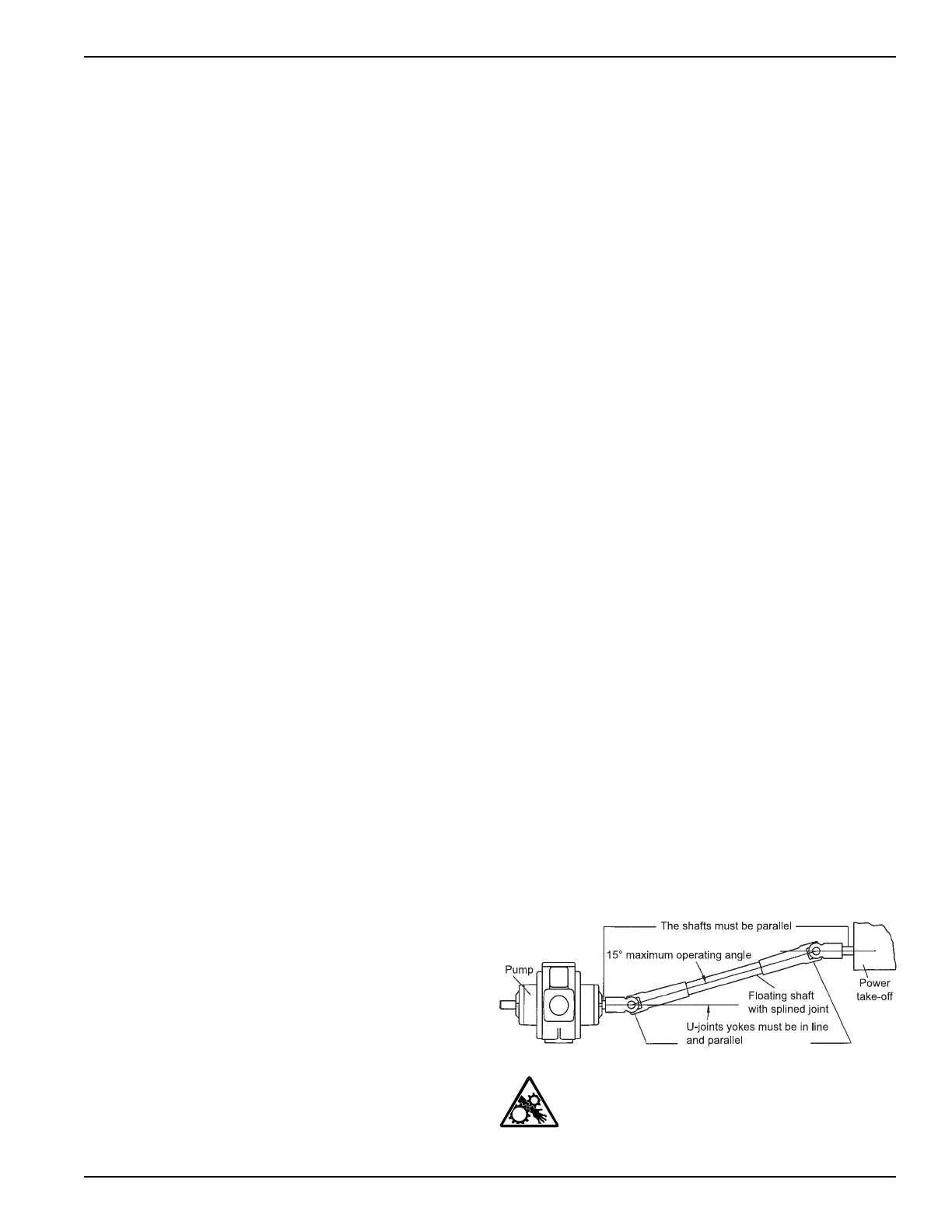

First, the driver shaft and the driven shaft must be parallel

to one another within plus or minus one degree. Improper

alignment will cause jerking and back and forth “whip” to the

pump shaft; thereby imparting a surging pulsation to the liquid

flow which results in noise, vibration and abnormal wear.

Second, the angle of the ‘’floating’’ shaft should be within

the limits for the particular equipment being used (usually

a maximum of 15° at pump speeds up to 800 RPM). To

ensure that shaft expansion or contraction does not distort

the drive system, a splined slip joint should be placed

between the two universal joints. Again, the drive shaft

should be of the “splined” or slip type to permit the shaft to

adjust for PTO movement and twisting of the truck frame. A

fixed drive shaft transmits the forces directly to the pump

and PTO which will shorten the life of both considerably.

Third, the yokes of the drive shaft universal joints must be

in a parallel position. Figure 1 below illustrates the proper

arrangement of the yokes.

Improperly installed U-joints will cause premature failure of

U-joints as well as bearings in the pump and PTO. Properly

mounted, the second universal gives uniform motion to

the drive shaft by compensating for the rotational error

introduced by the first U-joint. An even number of universal

joints (2, 4, 6 etc.) should always be used. An odd number

of U-joints will cause unbalanced pump shaft rotation. This

problem becomes greater with increased angularity.

Other points to consider include the proper sizing of the

shaft components with a maximum horsepower load to be

expected, good alignment of hanger bearings and proper

pump coupling alignment.

Improper PTO systems account for a high percentage of

truck pump failures. Always remember to disengage the

clutch before shifting the PTO into gear. Shifting the PTO into

gear without disengaging the clutch imparts an enormous

shock on the PTO, drive shaft, pump and meter and will

soon damage one or all of them.

For proper installation of pump drives, follow the rules

listed below:

1. Driver shaft and pump shaft must be parallel, plus or

minus one degree.

2. Operating angle of the ‘’floating’’ shaft must be 15°

maximum.

3. Universal yokes must be in line and parallel.

4. Splined slip joints must be used where needed.

5. Use an even number of universal joints.

Figure 1: Shaft alignment

Note: A drive shaft guard between the pump and

PTO should be installed (not shown).

6. Always use the least practical number of shafts.

5

Loading...

Loading...