14. If you have the standard bypass valve, remove the

bypass valve cap and turn the adjustment screw

counterclockwise to relieve the spring tension.

Remove the four 3/8 in. bolts from the bypass valve

cover. Use caution as a small amount of spring

tension will remain on the bypass valve spring

before complete bolt removal. Inspect bypass

valve, spring, and bypass valve cap gasket for wear,

abrasions, etc. Replace if damage is found.

15. If you have an Air Operated Valve (AOV), ensure the air

supply pressure has been relieved and the supply line

disconnected from the valve housing. Remove the AOV

cap and discard the O-ring from underneath. Remove

the retainer ring and locknuts from the adjustment stem.

Remove the four 3/8 in. bolts and lockwashers from

the AOV housing. Carefully remove the AOV assembly

from the pump. Remove and discard the gasket and

clean the gasket areas. Remove the two recessed-

head machine screws and the diaphragm cover plate.

Slide the diaphragm assembly out from the housing.

Remove the intermediate vent plate from between the

two diaphragms. Inspect the diaphragms, spring, and

valve for abrasions and replace if necessary.

Vane Replacement

NOTICE: ONLY QUALIFIED TECHNICIANS SHOULD

PERFORM MAINTENANCE AND THEY MUST FOLLOW

THE APPROPRIATE PROCEDURES AND WARNINGS

PRESENTED IN MANUAL.

1. Follow steps 2–6 in the “Pump Disassembly Instructions”

section of this manual to remove the head assembly

from the non-PTO side of the pump.

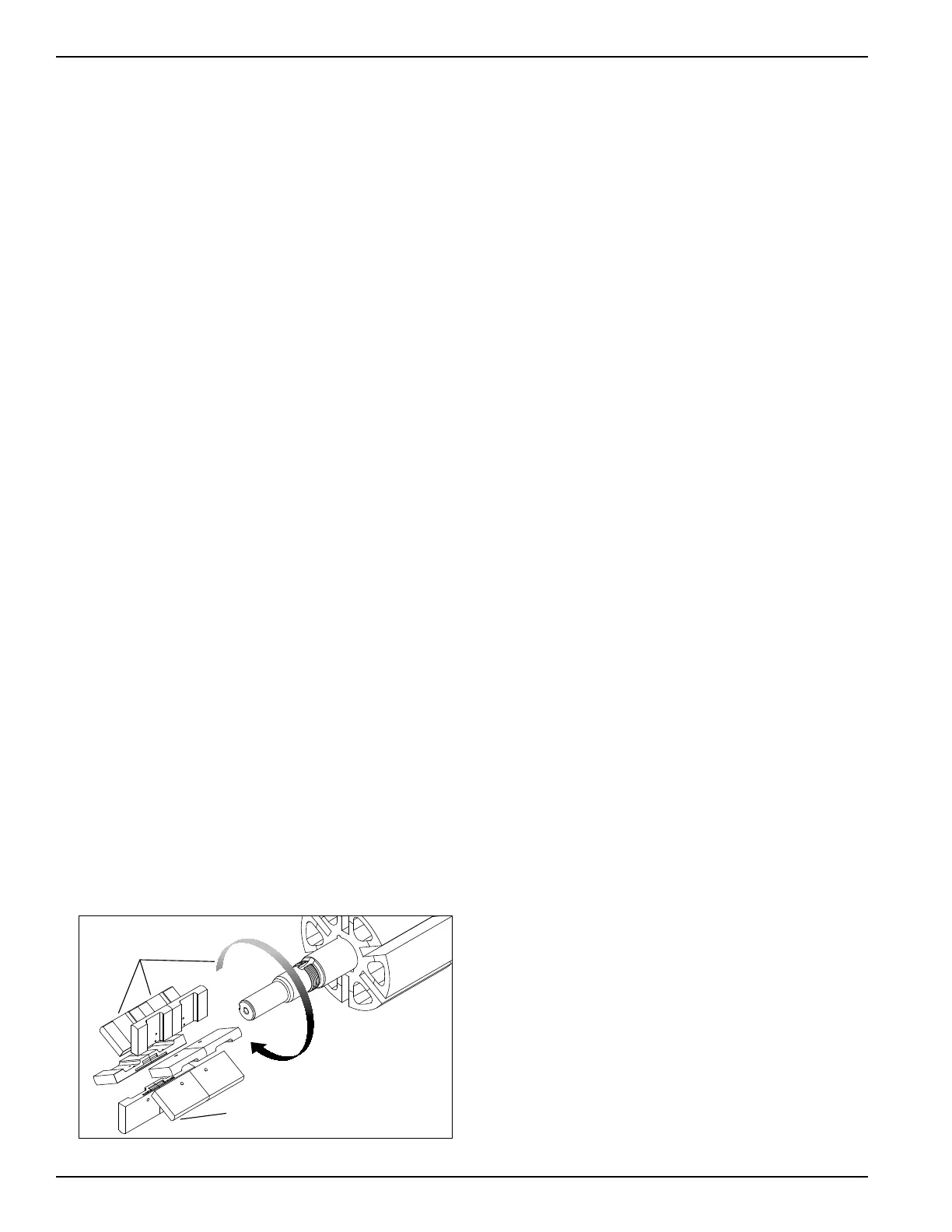

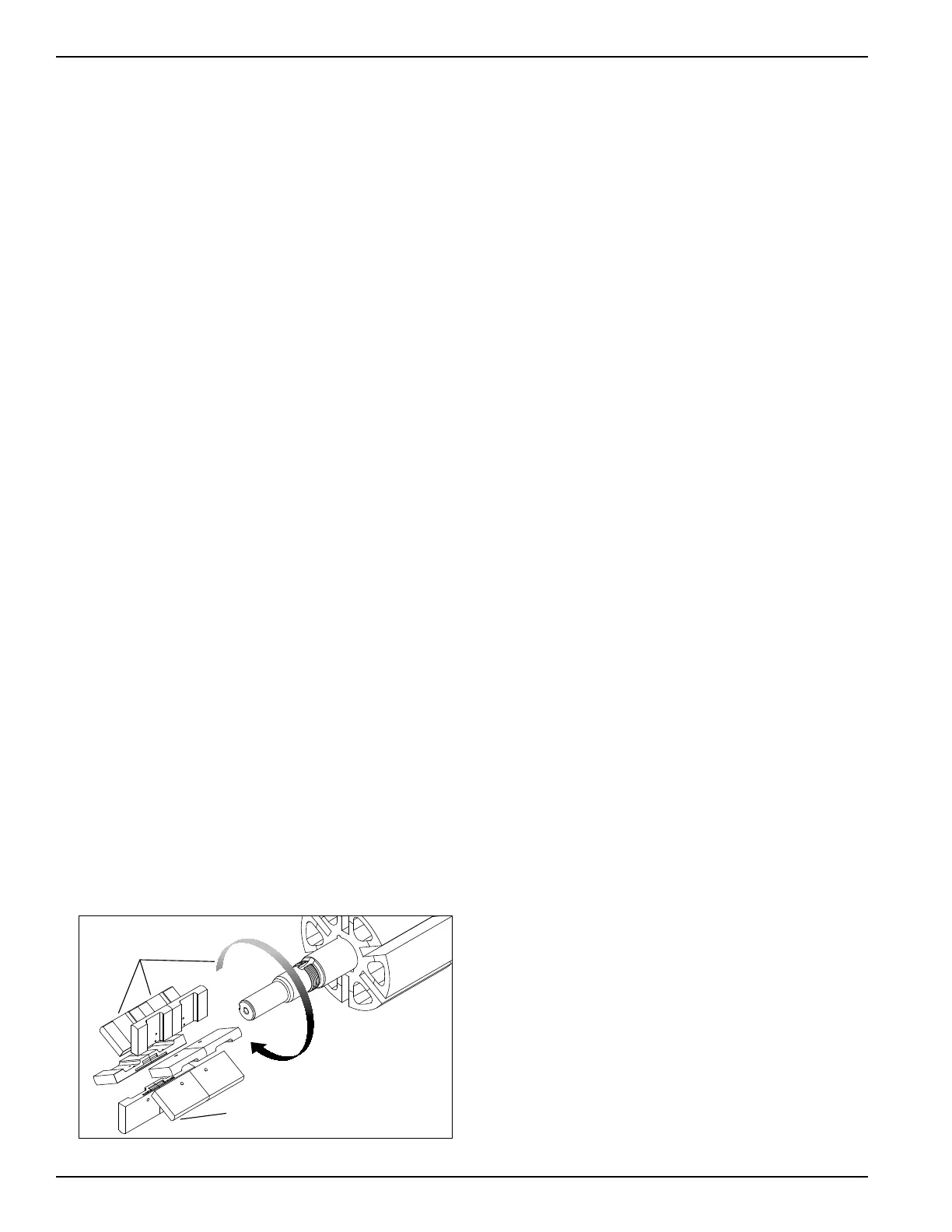

2. Turn the shaft with your hand until a vane is in the top

(12 o’clock) position of the rotor. Remove the vane.

3. Position a new vane so the rounded edge faces out

from the pump and the relief grooves face towards the

direction of rotation (see Figure 10).

4. Repeat steps 2 and 3 until all vanes have been replaced.

5. Follow steps 2–7 and 12–13 of the “Pump Assembly

Instructions” section of this manual to reassemble

the pump.

Relief grooves

face the direction

of rotation

Rounded edge out

Figure 10: PT30 model shown above

Bypass Valve Assembly

1. Place the bypass valve into the bypass valve bore of

the pump casing with the fluted end inward.

2. Insert the bypass valve spring and spring guide

against the bypass valve.

3. Attach a new bypass valve gasket and the bypass

valve cover onto the pump casing.

4. Tighten the bypass valve adjusting screw into the

bypass valve cover until it makes contact with the

spring guide.

NOTICE: THE BYPASS VALVE SETTING MUST BE

TESTED AND PROPERLY ADJUSTED BEFORE

PUTTING THE PUMP INTO SERVICE. PLEASE SEE

“BYPASS VALVE ADJUSTMENT”.

5. After the bypass valve has been adjusted correctly,

attach the bypass valve cap and gasket.

Air Operated Valve (AOV) Assembly

1. Install the intermediate vent plate between the two

diaphragms ensuring proper orientation with the screw

holes in the housing. Slide the diaphragm assembly

into the housing and install the diaphragm cover plate

and recessed-head machine screws and tighten

securely. Install this assembly with the valve, spring,

and gasket to the pump using the four 3/8 in. bolts

and lock washers and torque to 15 ft•lbs. Install both

locknuts all the way down the adjustment stem and

replace the retainer ring. Install the new O-ring and

AOV cap. Refer to Air Operated Valve Adjustment for

adjustment procedure.

2. Grease bearings per the instructions listed under

Maintenance of Your Pump System.

3. Install the pump according to the installation guidelines

mentioned previously.

12

Loading...

Loading...