PTO selection and drive system design is extremely important.

The PTO should have an average output speed up to 640 RPM

to maximize the performance of the PT-Series pump when the

truck engine is operating at the recommended speed.

The designer of the drive system must select a PTO drive

shaft capable of meeting the torque requirements of the

pumping system.

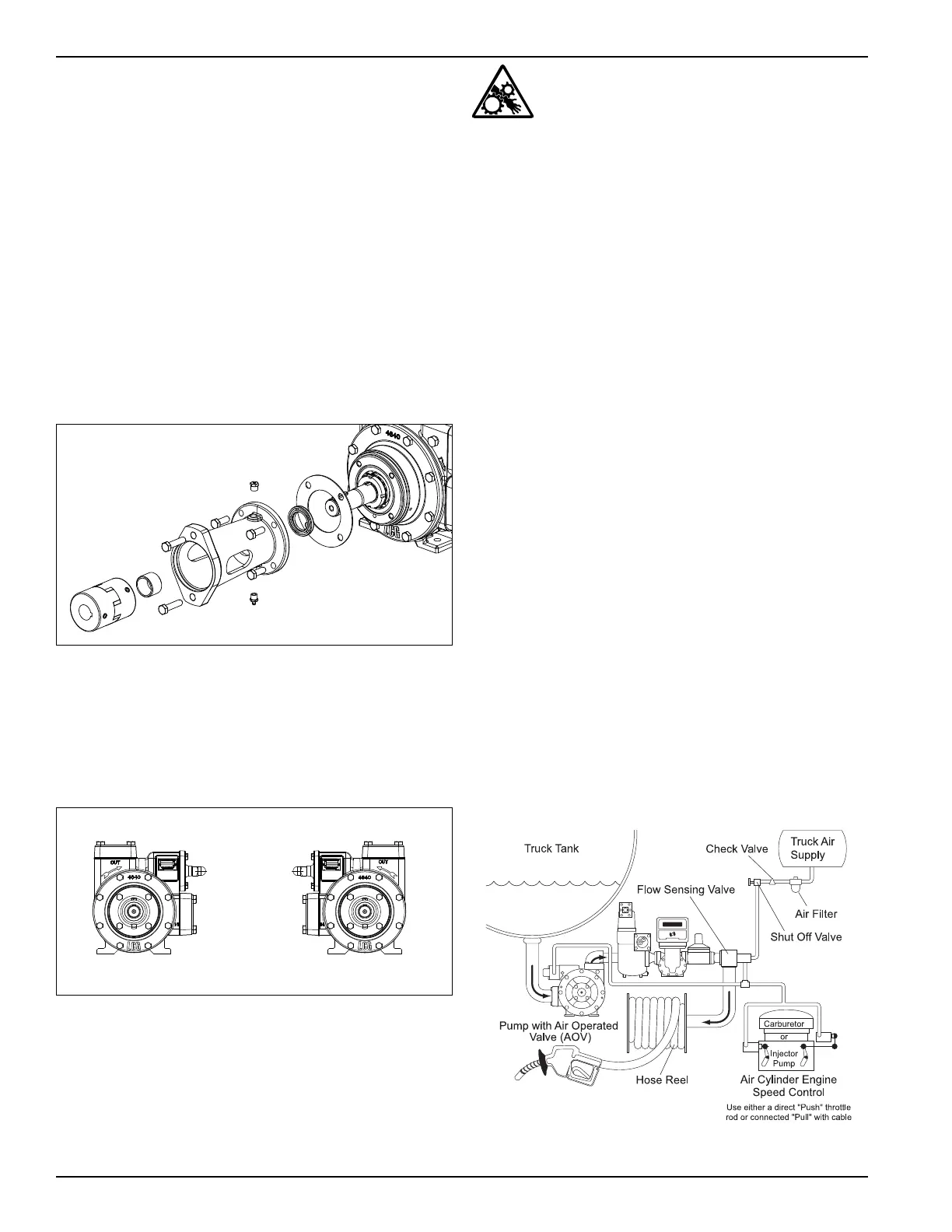

Hydraulic Drive Installation

Hydraulic motors must be well supported and keep their

shafts parallel to the pump shaft. To drive PT pumps

hydraulically, Liquid Controls Group provides a close-

coupled hydraulic motor adapter. The adapter aligns the

hydraulic motor drive and the pump shaft via a lockring

and a flexible coupling connected to a keyed shaft. This

adapter must be lubricated with grease at least every three

months. Refer to the “Bearing Lubrication” section of this

manual for instructions.

Figure 2: Hydraulic Drive (see Appendix E for Part Details)

Pump Rotation

For proper pump rotation, make sure the pump’s rotation

arrows match the pump driver rotation (see Appendix E for

parts details). NOTE: PT-Series pumps are double ended

shafts and can be mounted in either position.

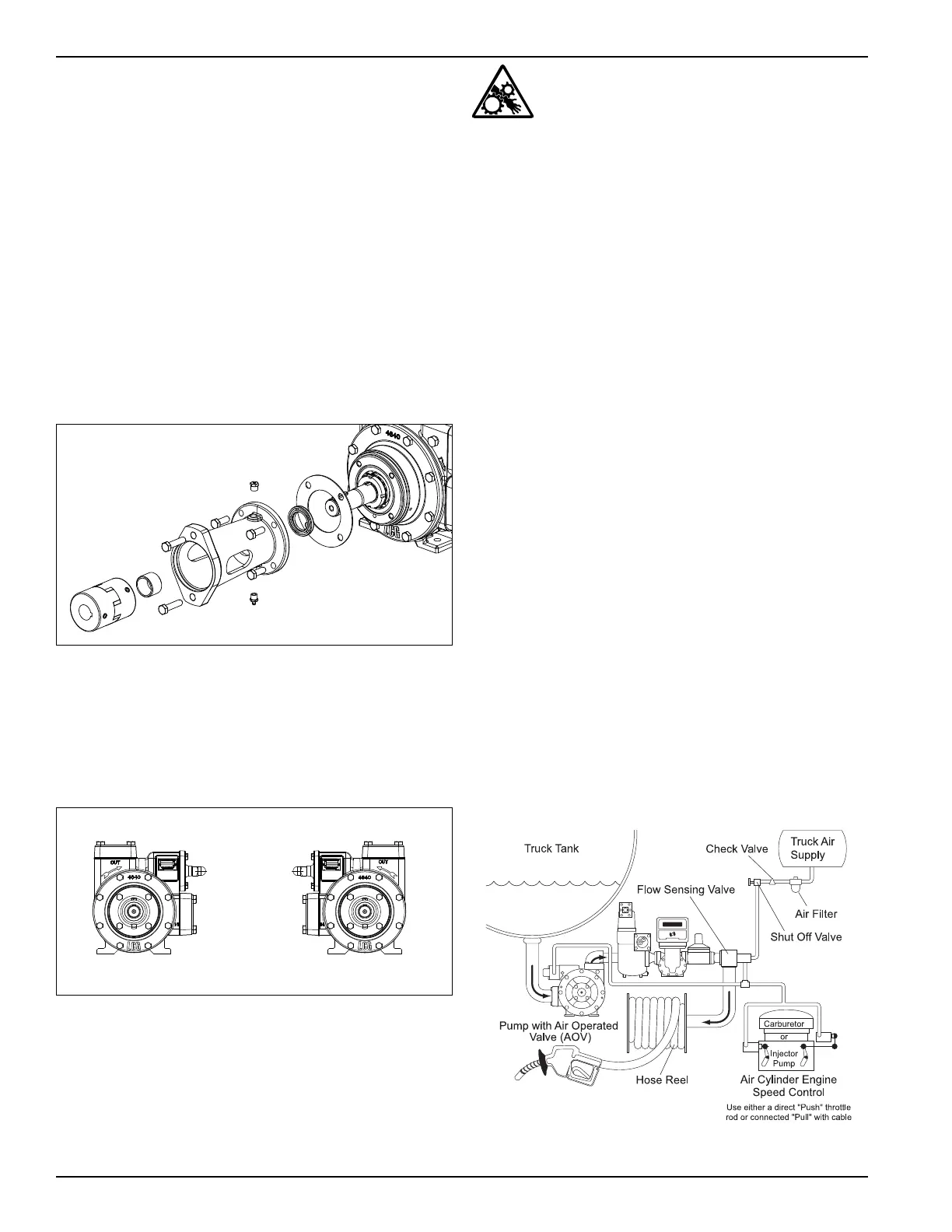

Direction of Rotation

Left hand/counter clockwise rotation

(PT25)

Right hand/clockwise rotation

(PT25)

Figure 3: Direction of Rotation

To Change Pump Rotation

The PT Series pump is equipped with a double ended rotor

and shaf t, the pump motors can be driven from either shaft

end. To change rotation, rotate the pump 180 degrees. The

opposite shaft will then become the driven shaft.

Be certain the shaft protector (see Part

Details) is mounted over the non-driven shaft

end. Operation without shaft protector can

cause serious personal injury, major property damage,

or death.

If the pump must be disassembled to reverse rotation. Refer to

the “Maintenance of Your Pump System” for instructions.

Operation of the PT-Series

Truck Pump

The following steps should be performed for the initial

pumping operation:

1. Close the shutoff valve on the end of the delivery hose.

2. Start the pump and cycle the nozzle open and closed

to clear all air from the system.

3. Check the discharge pressure on the outlet of the

pump. This pressure is typically set at 80 to 95 psi.

4. Bypass Valve Adjustment

For a standard bypass valve, locate the adjustment

set screw under the bypass valve cap (see Appendix

E for parts details). Turn adjustment screw clockwise

to increase pressure and flow. Turn counter clockwise

to decrease pressure and flow.

Close the nozzle and check the bypass pressure. If

too high, turn adjustment screw counter clockwise

until desired pressure is reached.

With the hose nozzle open, adjust the pump bypass valve

setting to the desired flow rate. Close the nozzle slowly

and check the system pressure. CAUTION: DO NOT

EXCEED A CLOSED NOZZLE PRESSURE OF 125 PSI.

Replace bypass valve cap and bypass valve cap

gasket with seal washer and tighten.

5. Air Operated Valve (AOV) Adjustment

Figure 4: Typical truck delivery system using an AOV.

6

Loading...

Loading...