3. Check V-belt drive or direct drive coupling alignment.

Misalignment will accelerate wear on the drive system,

motor bearings and pump.

4. Check motor for proper wiring.

5. Review complete system to make certain the function

of every valve and piece of equipment is clearly

understood. Everyone operating this system must be

properly trained in normal operating procedures and

emergency procedures in the event of a malfunction.

6. Close all hose valves.

7. Slowly open the storage tank bottom shut-off valve

(suction line to the pump). Immediately check the

system for leaks.

9. Record all pressure gauge readings, especially the

pressure gauge located at the discharge of the pump.

Start the pump and circulate the liquid through the

internal bypass valve.

10. Verify the proper pump rotation direction by referring

to the part details in Appendix E or the “Pump

Rotation” section at the beginning of this manual.

11. Your pump has an internal bypass valve so it must

be adjusted to the required setting. The internal

bypass valve may be adjusted while the pump is in

operation by removing the bypass valve cap. Turning

the adjusting screw clockwise increases the internal

bypass valve pressure setting and counterclockwise

decreases the pressure setting.

12. An amp meter may be used by adjusting the bypass

valve until the amp meter indicates the full load motor

amperage rating shown on the motor nameplate or

maximum rated differential, whichever comes first. If

the motor overload protection device stops the motor

in this period the bypass valve setting is too high

and should be readjusted. After a satisfactory setting

is achieved, “seal” the bypass valve cap to prevent

tampering with the adjustment.

13. After initial operation, re-check the strainer screen.

Maintenance of Your Pump System

Your PT-Series pump requires regular maintenance

and care like all mechanical equipment. A neglected or

improperly repaired pump will result in premature failure

and cause unsafe conditions. To promote product longevity

and safety, maintenance must be performed by properly

trained technicians. Make sure all safety systems are in

place and the system pressure has been relieved before

attempting ANY maintenance.

Normal wear parts are the mechanical shaft seals,

bearings, vanes, vane drivers and sideplates. All of these

parts plus O-rings and grease seals are offered in the

“repair kit.” Use only genuine Liquid Controls Group

replacement parts when repairing your PT-Series pump.

Follow the instructions provided with the parts.

When it becomes necessary to repair your pump or

remove it from the system, you must be absolutely

certain that all product being pumped is bled from the

pump and connected piping. Once all the product has

safely been bled from the pump and connected piping,

make certain no pressure is left in the system. SPECIAL

CARE MUST BE TAKEN DURING THE BLEED DOWN

PROCESS TO AVOID DANGER TO PERSONNEL AND

PROPERTY IN THE AREA. Take your time in bleeding

your system and make proper provisions to vent or

capture the product in accordance with local regulations.

ONLY A PROPERLY TR A INED IND IVIDUAL SHOULD BE

ALLOWED TO BLEED A PUMPING SYSTEM.

Pump Maintenance Schedule

Make sure the transfer hoses are not “kinked’’. A kinked

hose can cause excessive pump discharge pressure.

Always make sure your hoses are not out of date.

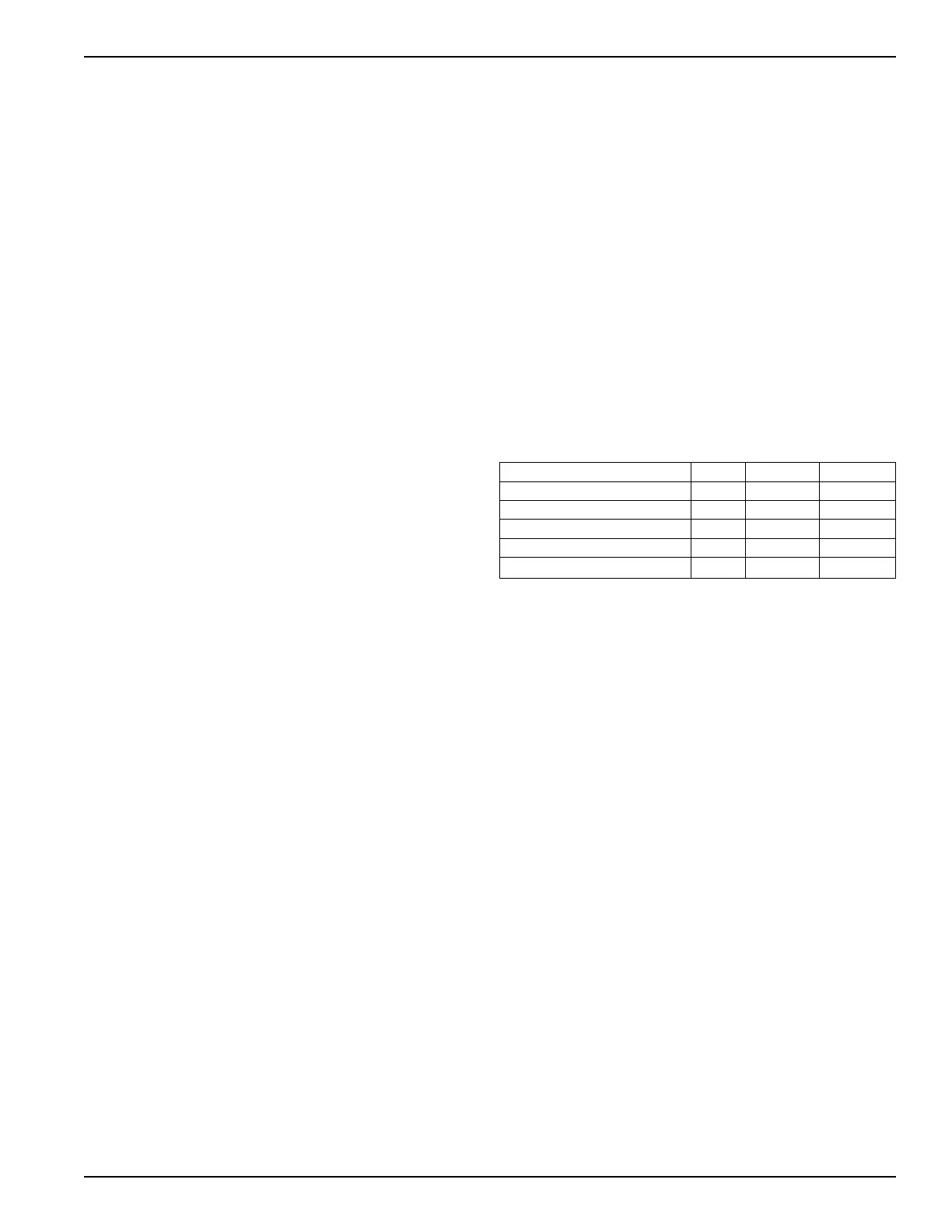

Daily Monthly 3 Months

Lubricate bearings •

Inspect drive coupling •

Clean Inlet Strainer •

Check for leaks •

Inspect hose and ttings •

Bearing Lubrication

NOTICE: AVOID ENTANGLEMENT IN MOVING PARTS.

DO NOT LUBRICATE PUMP BEARINGS, HYDRAULIC

ADAPTER COUPLING OR ANY OTHER PARTS WHILE

THE PUMP IS ACTIVE.

There are two lubrication points in which to grease

the pump bearings; one zerk per bearing cap located

at opposite ends of the pump. Two grease relief and

ventilation fittings have been provided—one at each

end of the pump—to help prevent over greasing the

bearings. Over greasing can cause seal failure if grease

passageways are blocked in some way. Remove relief

fittings or confirm free movement of relief prior to

greasing bearings. Clean each fitting before lubricating

the bearings. This practice helps to prevent foreign

material contamination of the bearings and accidental

over-pressurization of the mechanical seals. Use only

NLGI grade 2 ball bearing grease.

Lubricate ball bearings and hydraulic motor couplings (if

equipped) a minimum of every three months.

Greasing Procedure:

1. Remove grease relief fittings from bearing covers or

hydraulic motor adapter.

2. Grease with a hand gun until grease escapes from

grease relief fitting port.

3. Return grease relief fittings to bearing covers.

9

Loading...

Loading...