For pumps equipped with an Air Operated Valve (AOV)

assembly, air must be supplied from the truck air system

via a flow sensing valve. Approximately 70 psi (4.8 bar)

minimum air pressure is required to properly operate

the air operated valve. THE AIR PRESSURE MUST NOT

EXCEED 125 psi (8.6 bar). The sensing valve should

be installed in accordance with the diagram shown in

Figure 4. This system depicts the additional use of a

throttle control which is optional. All adjustments must

be made at normal operating speeds.

5.1 Set the low pressure adjustment first by slowly

closing the nozzle to relieve the air pressure in

the AOV assembly.

5.2 Remove the AOV cap and O-ring (see Appendix

E for parts details).

5.3 Turn the low pressure adjustment stem counter-

clockwise to decrease the bypass pressure and

vice versa to increase the pressure.

5.4 Re-install the O-ring and AOV cap and tighten

securely.

5.5 Open and close the nozzle several times to ensure

proper setting and repeatability.

5.6 Slowly close the delivery nozzle again to relieve

the air pressure in the AOV assembly.

5.7 Remove the AOV cap and O-ring.

5.8 Adjust the locknuts clockwise to decrease delivery

flow rate and/or pressure and vice versa to increase

the flow rate. NOTE: Make sure the locknuts are

securely locked against each other before re-

installing the adjustment stem cap and O-ring.

5.9 Slowly open the delivery nozzle and note delivery

flow rate and/or pressure.

5.10 Repeat steps 5.7–5.9 until desired flow rate and/or

pressure are achieved.

6. You may increase the speed of the pump as long as

it increases the flow through the delivery nozzle. It is

recommended to turn the pump at approximately 575

RPM for optimum performance. However, the pump

can be safely turned to 640 RPM if system conditions

permit (refer to Appendix B).

NOTE: IF PUMP SPEED IS INCREASED, BE CERTAIN

THE METER AND PIPING SYSTEM WILL HANDLE THE

INCREASED FLOW AND PRESSURE!

Installation of the PT-Series

Stationary Pump

NOTE: NEW PUMPS CONTAIN RESIDUAL TEST FLUID

SO IT MAY BE NECESSARY TO FLUSH THE PUMP

PRIOR TO USE. ALL PUMPS SHOULD BE INSTALLED

IN AN AREA THAT IS WELL VENTILATED.

The installation of the PT-Series pumps are simple.

However, in order for the pump to deliver optimum

performance, the principles discussed in this book should

be followed. The piping details provided illustrate methods

proved by hundreds of installations. Your own needs may

require light variations, but every effort should be made to

follow the recommendations identified in this manual.

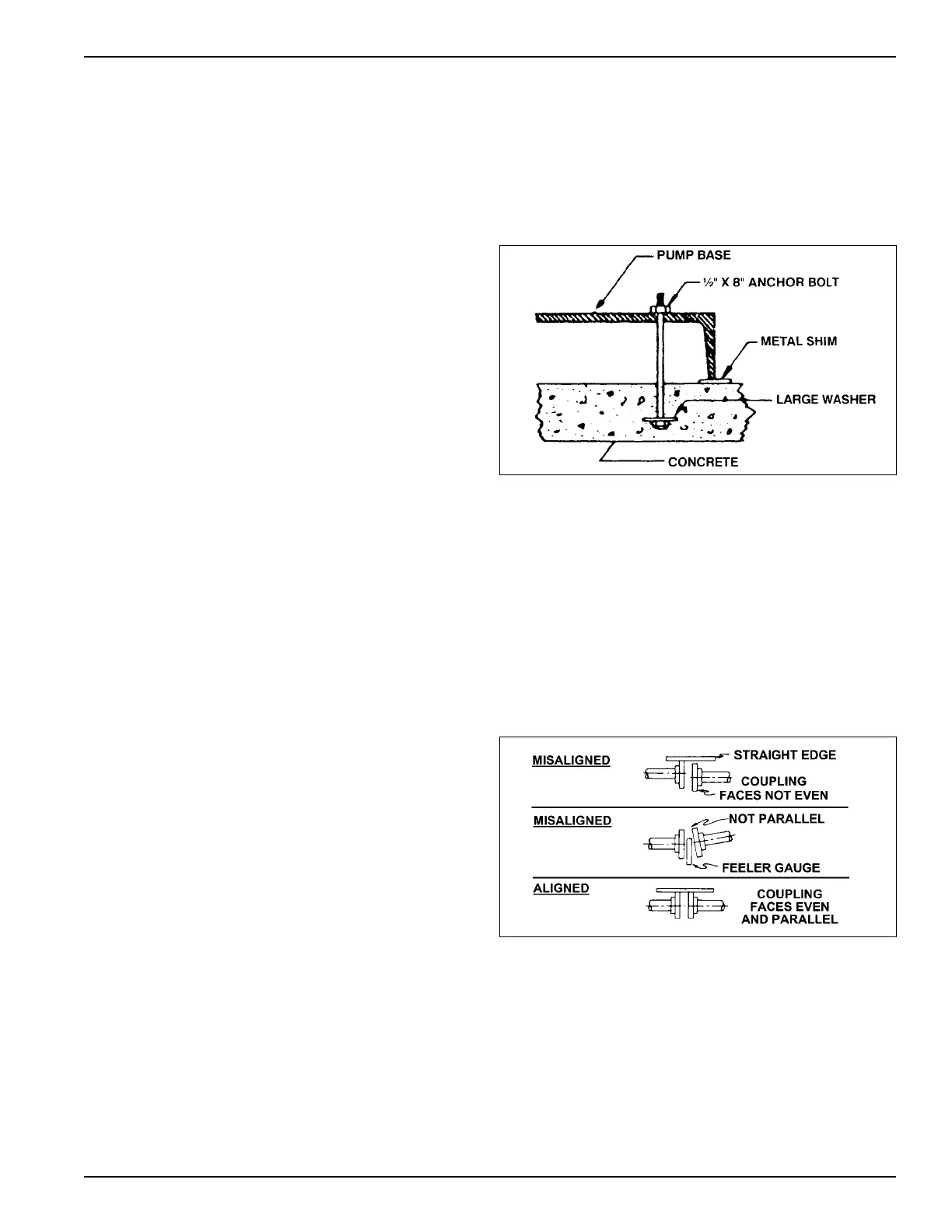

The foundation for the pump is important. The foundation

must be firm, level and preferably made of concrete. The

suggestions in figure 5 should be observed.

Figure 5

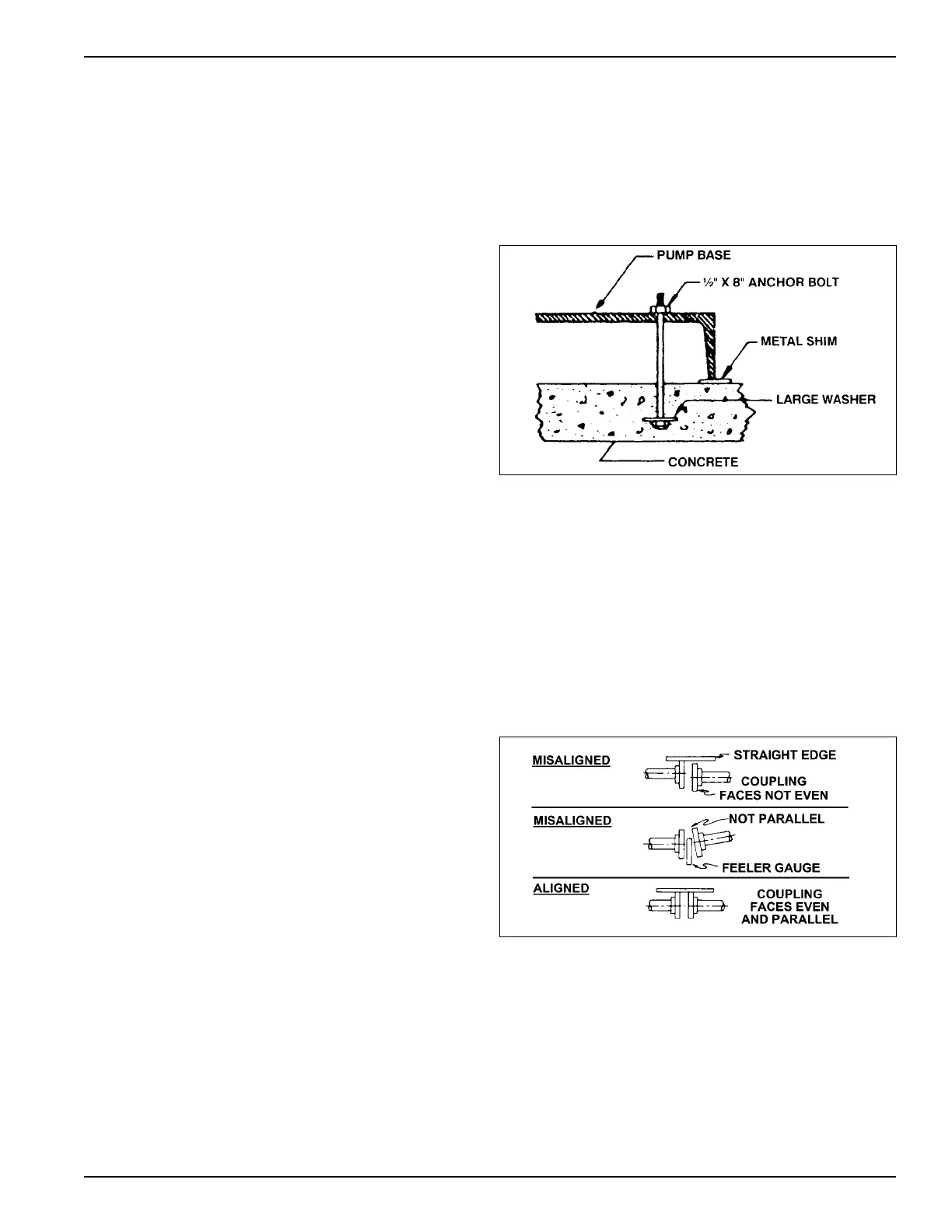

Coupling alignment

The coupling alignment must be near perfect to give

quiet, long-life service to the pump and driver. The pump

and driver shafts are carefully aligned at the factory but

always should be checked after the pump is installed and

before the initial operation.

Lay a straight edge across coupling halves, top, and side;

both positions must line up to be correct (see figure 6). If

misalignment exists, adjust the shims between the pump base

and the foundation until exact alignment is accomplished.

Figure 6

No pump can discharge more liquid than it receives, so

the pump location and the inlet piping must be given

careful attention. If the inlet piping is inadequate to supply

the demand of the pump, you may expect trouble.

The installer and/or the user must take into account

the following:

• The pump must be located as near the storage tank

as possible. The complete inlet line, including the

7

Loading...

Loading...