It is important to check and make maintenance for protector so as to ensure operators' safety.

Periodical check and maintenance shall be made. A detail for check and maintenance is showed as

form 8.1

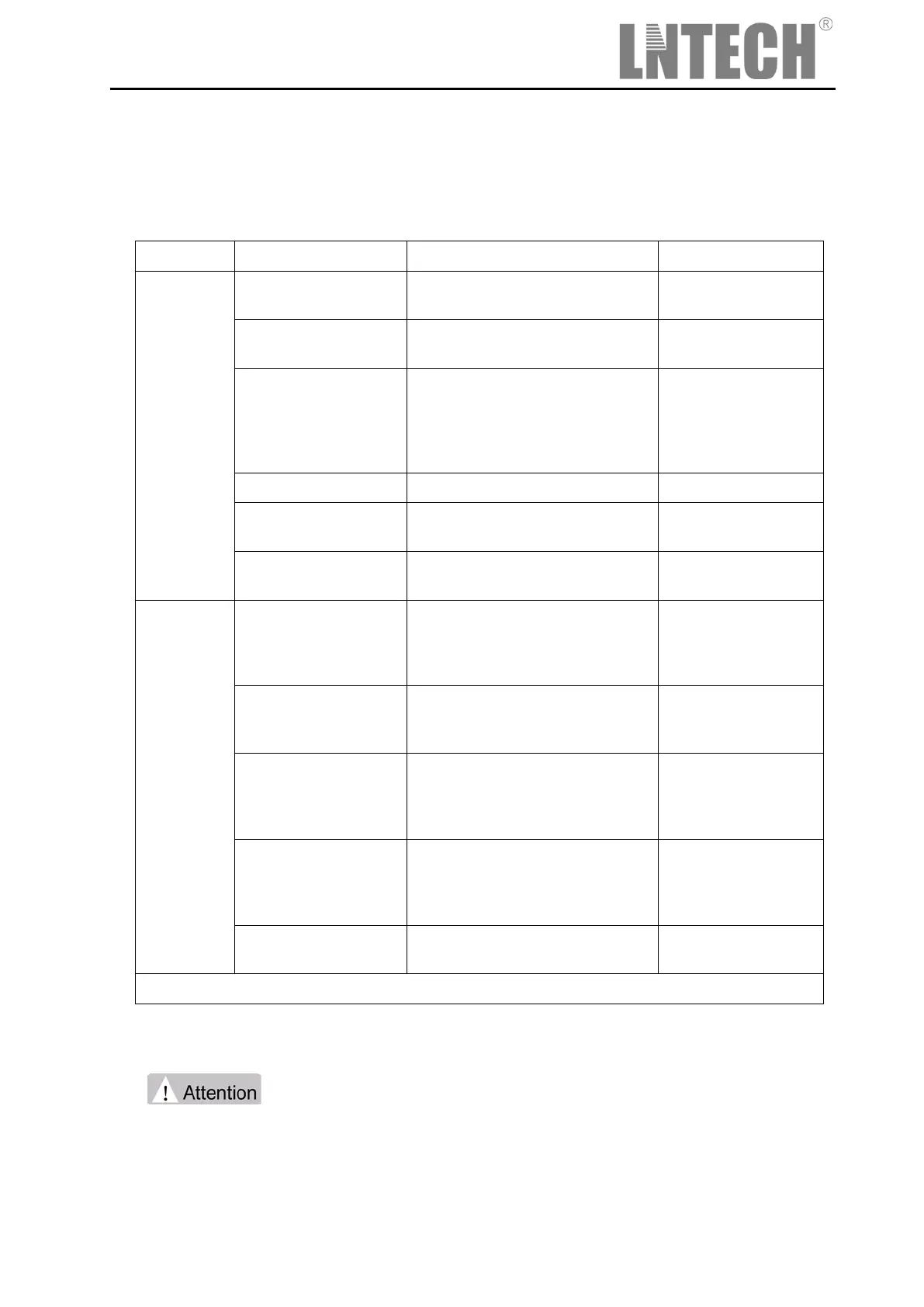

Form 8.1 Check and maintenance

Item Contents Means Time

Check

Check for light curtain face

Conrmation of all passing, reecting face

clean and no broken

Before operating

Conrmation of incepting

light (test every beams)

Block one by one beam of light curtain;

check if indication states are normal

Before operating

Check for protection

function

In entire protected slide travel (or ownward

strokes between 30 to 180 degrees, is set

cam switch for "no protection" in back-

way), block light curtain, the slide of press

should stop immediately

Before operating

Check for screws Conrmation of all screws tightly xed Six months

Check for wiring terminates

Conrmation of all screws tightly xed, and

all wiring well connected

Six months

Check for relay

Conrmation of relays tightly installed, well

contacts and normal operation

Six months

maintenance

Replace relays

Prize up stopper gear on the plastic tie

with the screw driver, release the tie,

remove the old relay and replace new then

re-tie tightly

More than life

Cleaning for light curtain

units

Clean with soft cotton yarn soaked water

or detergent, prohibit cleaning with organic

solvent

Implement based on

conditions

Replacing lters of sensor

If lter is broken, replace it immediately.

Unpack the end cover of sensor, pull out

the broken lter, insert the new one, and

then x the end cover

Implement based on

conditions

Replacing mirror

If mirror is broken, replace it immediately.

Unpack the end cover of reector, pull out

the broken mirror, insert the new one, and

then x the end cover

Implement based on

conditions

Fix and replace screws

Fix loosen screws tightly, replace the

damaged

Implement based on

conditions

Inspection is needed before operation unless periodic inspection

Check them before operating, besides periodic inspection.

8.2 Check and Maintenance

Loading...

Loading...