MigWeld™ 100 - 100 AMP MIG Welder 120v

Page 7 of 8

anything with the Torch Handle or an arc may be ignited.

12. Plug the Power Cord into its electrical outlet, presses the Current Switch to appropriate current and turn

the welder ON.

13. Lift the Torch Handle and continue pressing the Trigger until the wire feeds through two inches.

If the wire does not fed, view the Wire Feed Unit and see if the wire is being pushed.

If it is not, turn the welder OFF and add more tension to the Wire Feed Adjusting Spring (36).

14. Turn the welder ON again and press the Trigger.

15. Once the wire is exposed, turn the welder OFF.

16. Slide the Contact Tip over the wire and screw it into Torch Handle.

17. Replace the Nozzle and cut off any excess wire over two inches.

18. Secure the Cover.

NOTE: Duty Cycle: is a welding equipment specification, which defines the number of minutes , within a

10-minute period, during which a given welder can safely produce a particular welding current .

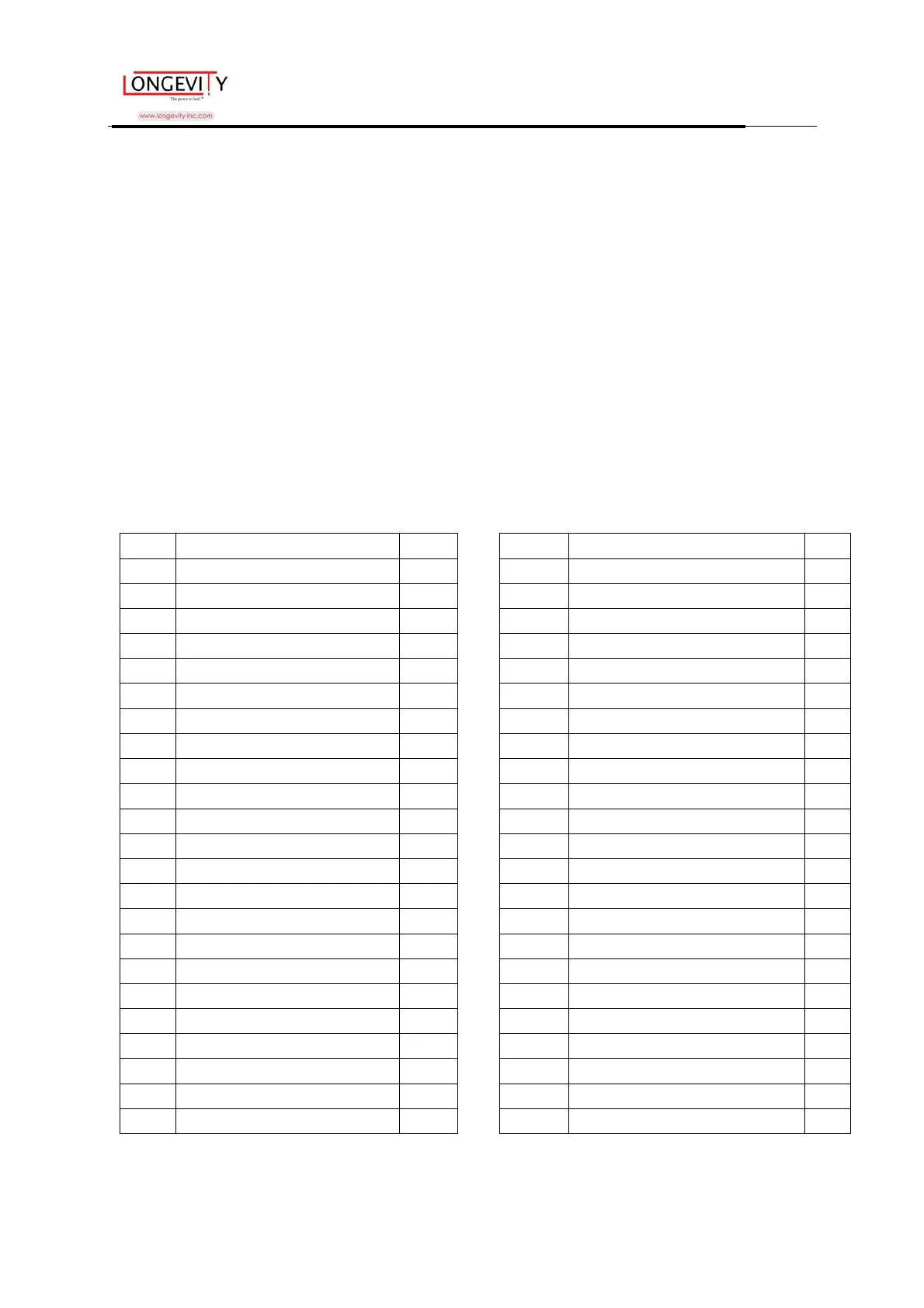

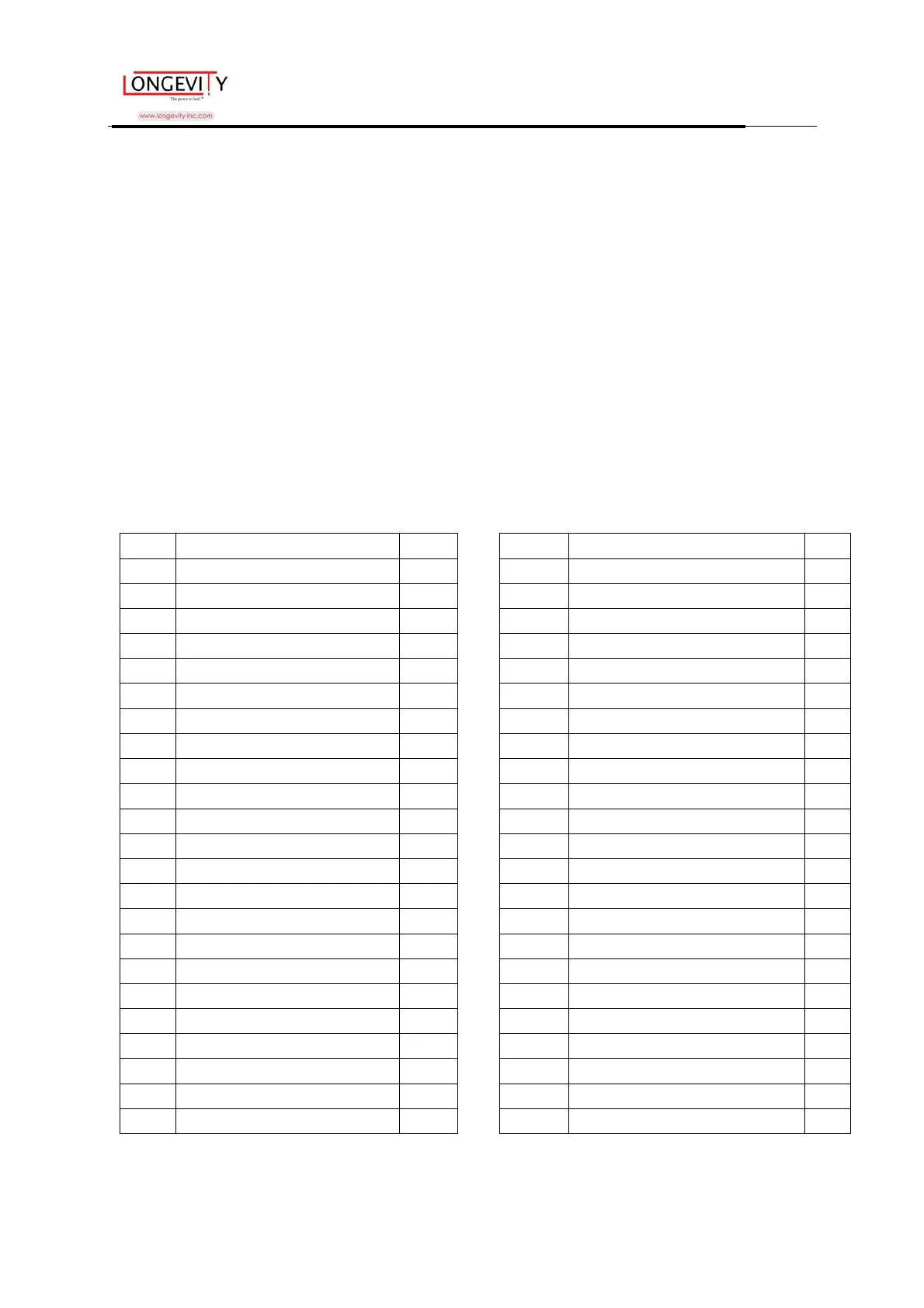

MIGWELD 100 Welder Parts List

Item# Description Qty. Item# Description Qty.

1 Torch 21 Middle Partition Board

2 Contact Tip 22 Overload Indicator Lamp

3 Nozzle 23 Wire Feed Unit

4 Liner 24 Reel Spring

5 Fixing Pole (A) for Gun Body 25 Wing Nut, M6

6 Fixing Pole (B) for Gun Body 26 Reel Locking Knob

7 Switch 27 Wire Reel

8 Cover Locking Spring 28 Reel Holder

9 Knob Cover 29 Self-tapping Screw, ST4.2×25

10 Nut 30 Handle

11 Speed Control Circuit Board 31 Cover

12 Right Side Panel 32 Power Cord

13 Left Side Panel 33 Ground Cable

14 Base Frame 34 Wire Feed Roller

15 Foot 35 Wire Feed Bearing

16 Wire Speed Knob 36 Wire Feed Adjusting Spring

17 Self-tapping screw.ST4.2*13 37 Adjustment Screw

18 Transformer Carriage

38 Face Shield

19 Thermostat 39 Wire Brush/ Hammer

20 Transformer

Loading...

Loading...