5 ENGLISH

Use an air hose as large and as short as possible to

assurecontinuous,efcientstaplingoperation.

Withanairpressureof0.49MPa(4.9bar),anairhose

with an internal diameter of over 6.5 mm and a length

of less than 20 m is recommended when the interval

between each stapling is 0.5 seconds.

Air supply hoses shall have a minimum working pres-

sure rating of 1.03 MPa (10.3 bar) or 150 percent of the

maximum pressure produced in the system whichever

is higher.

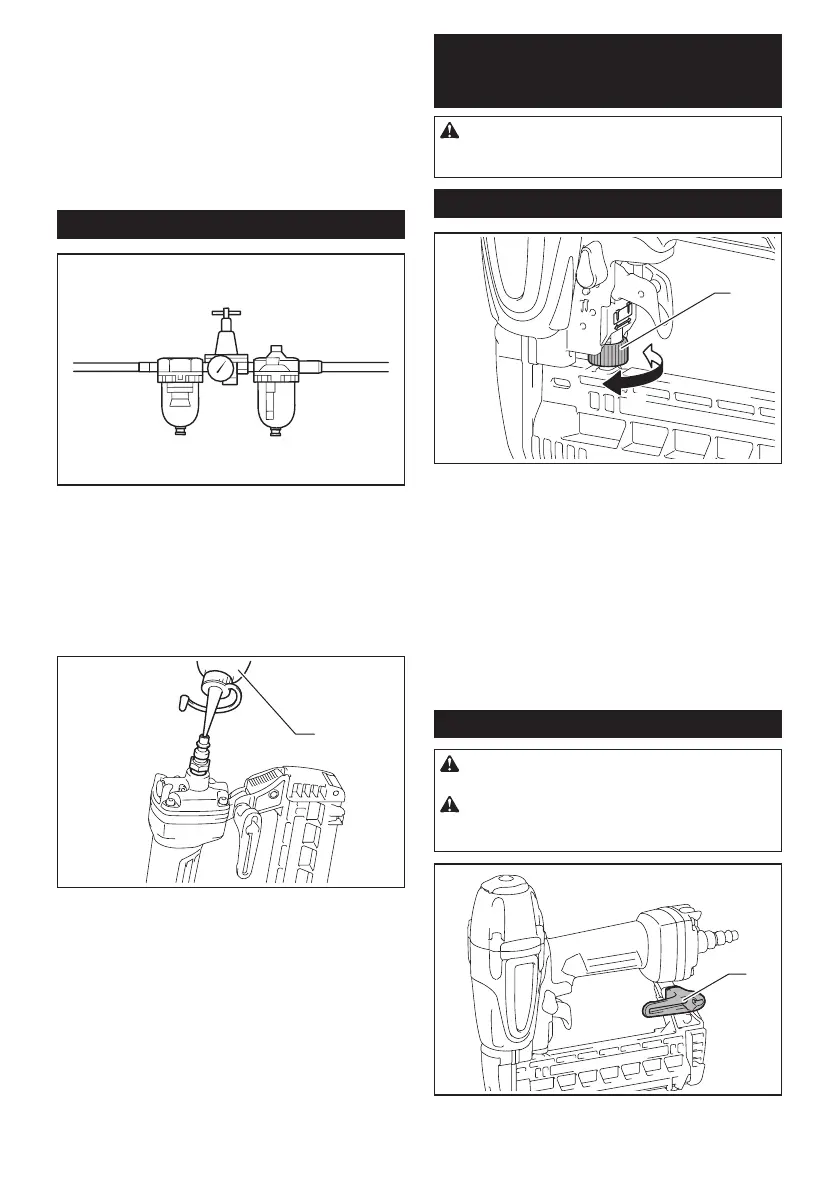

Lubrication

Toinsuremaximumperformance,installanairset(oiler,

regulator,airlter)ascloseaspossibletothetool.

Adjusttheoilersothatonedropofoilwillbeprovided

for every 50 staples.

Whenanairsetisnotused,oilthetoolwithpneumatic

tool oil by placing 2 (two) or 3 (three) drops into the air

tting.Thisshouldbedonebeforeandafteruse.

Forproperlubrication,thetoolmustberedacoupleof

times after pneumatic tool oil is introduced.

1

►1. Pneumatic tool oil

FUNCTIONAL

DESCRIPTION

CAUTION: Before adjusting or checking

function on the tool, always return the trigger and

disconnect the air hose from the tool.

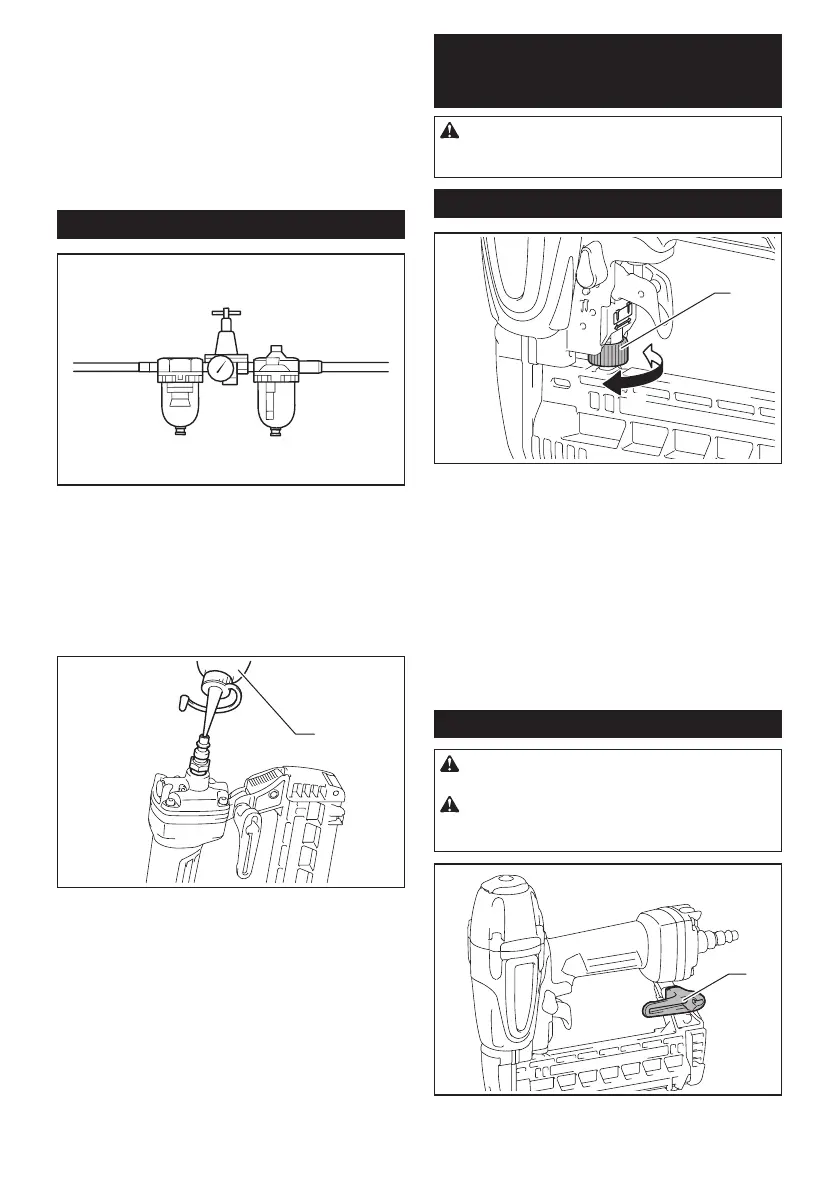

Adjusting depth of stapling

1

B

A

►1.Adjuster

Toadjustthedepthofstapling,turntheadjuster.

Thedepthofstaplingisthedeepestwhentheadjuster

isturnedfullyintheAdirectionshowninthegure.Itwill

becomeshallowerastheadjusteristurnedintheBdirection.

If staples cannot be driven deep enough even when the

adjusteristurnedfullyintheAdirection,increasethe

air pressure.

Ifstaplesaredriventoodeepevenwhentheadjusteris

turnedfullyintheBdirection,decreasetheairpressure.

Generallyspeaking,thetoolservicelifewillbelonger

when the tool is used with lower air pressure and the

adjustersettodeeperdepthofstapledriving.

Hook

CAUTION: Never hook the tool at high loca-

tion or on potentially unstable surface.

CAUTION: Do not hang the hook from the

waist belt.Ifthestapleraccidentallydrops,itmay

resultinmisringandpersonalinjuries.

1

►1. Hook

Thehookisconvenientforhangingthetooltemporarily.

Loading...

Loading...