1

2

3

4

Removing and installing pistons with conrods

112

Removing piston with connecting rod

D Remove oil pan and oil suction pipe,

see Page 62

D Removing cylinder heads, see page 85

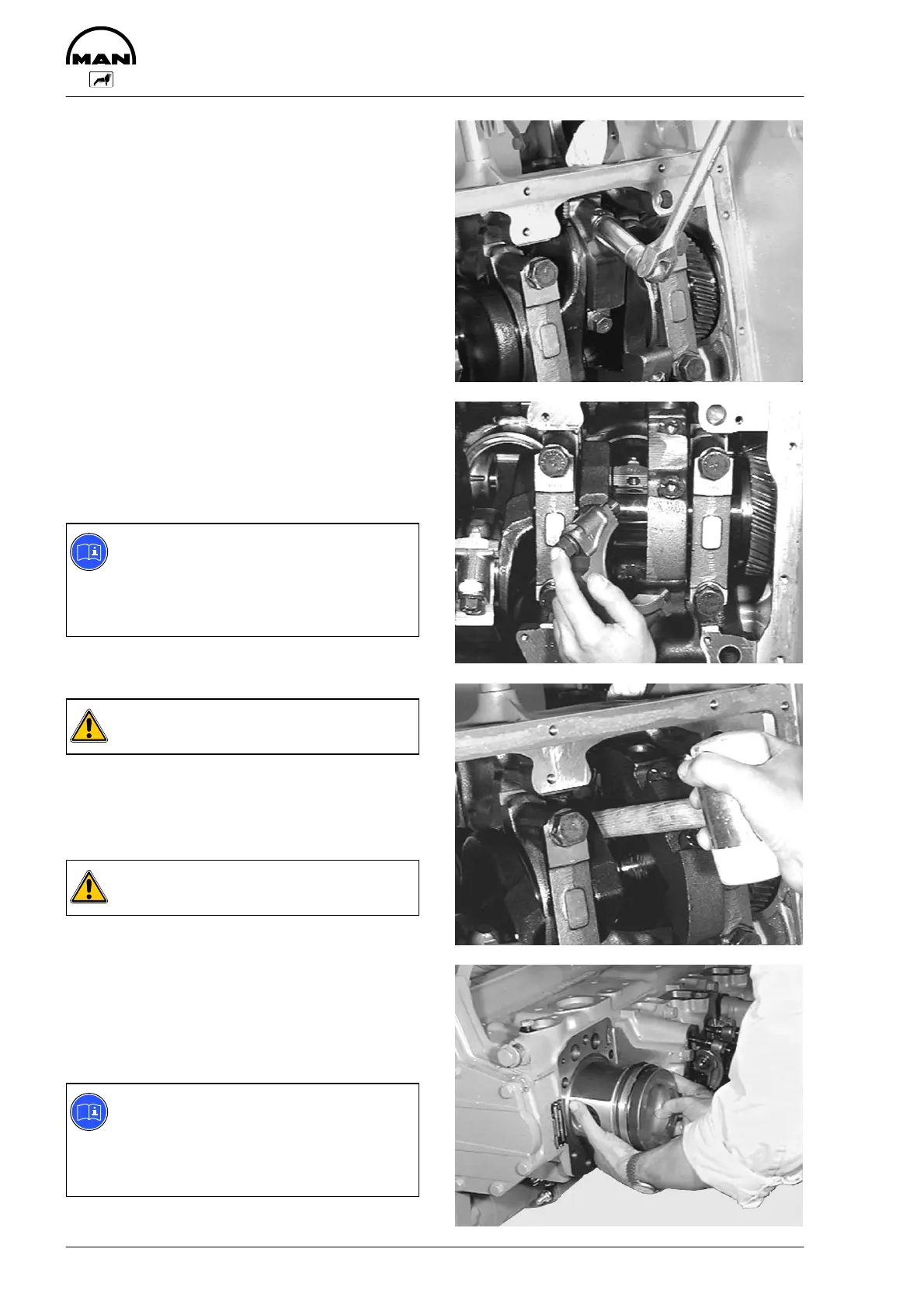

Fig. 1

Loosen and remove conrod bearing cover bolts.

Fig. 2

Remove conrod bearing covers with bearing bus-

hes; if necessary, assist with light blows from a

plastic hammer. expediting the procedure by

means of light strokes with a synthetic hammer if

necessary.

Note:

The conrod bearing covers are numbered

at the conrod foot; place to one side ac-

cordingly. arrage them in corresponding

order.

Remove combustion residues (oil carbon) from top

cylinder edge using a piece of hard wood.

Caution:

Do not damage the cylinder liners!

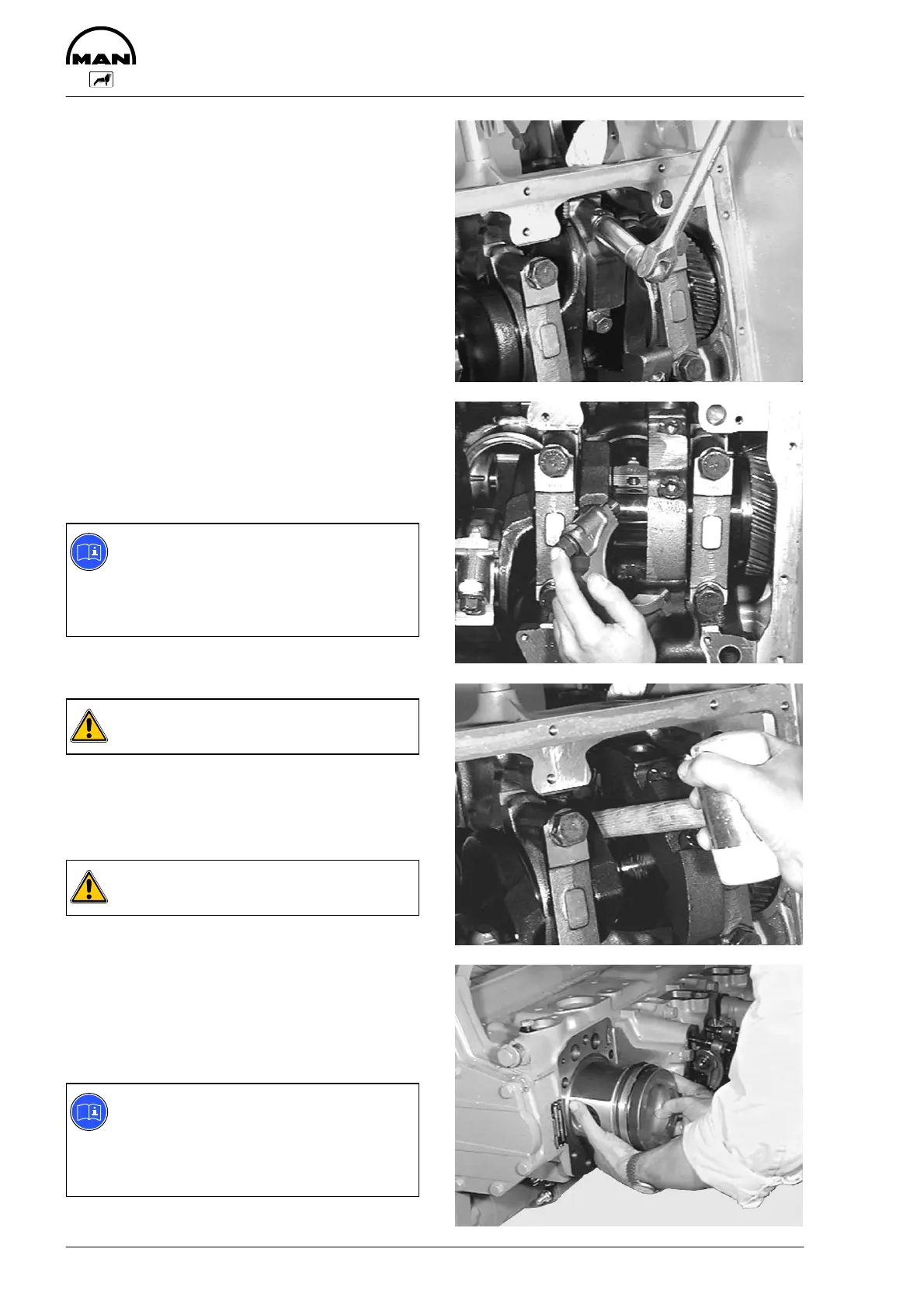

Fig. 3

Press out the conrod with piston upwards.

Caution:

Do not damage the oil injection nozzles!

Fig. 4

Place the piston with conrod beside the relevant

conrod bearing cover; if available, use storage faci-

lity. use deposit rack if available.

Perform visual check of piston and piston rings.

Note:

For remachined crankcase sealing surfa-

ces, there are repair pistons with 0.2, 0.4

and 0.6 mm lower dimension in compres-

sion height (see “Service Data”).

Loading...

Loading...