3

4

5

6

Checking and repairing fuel injectors

33

Disassembling fuel injectors

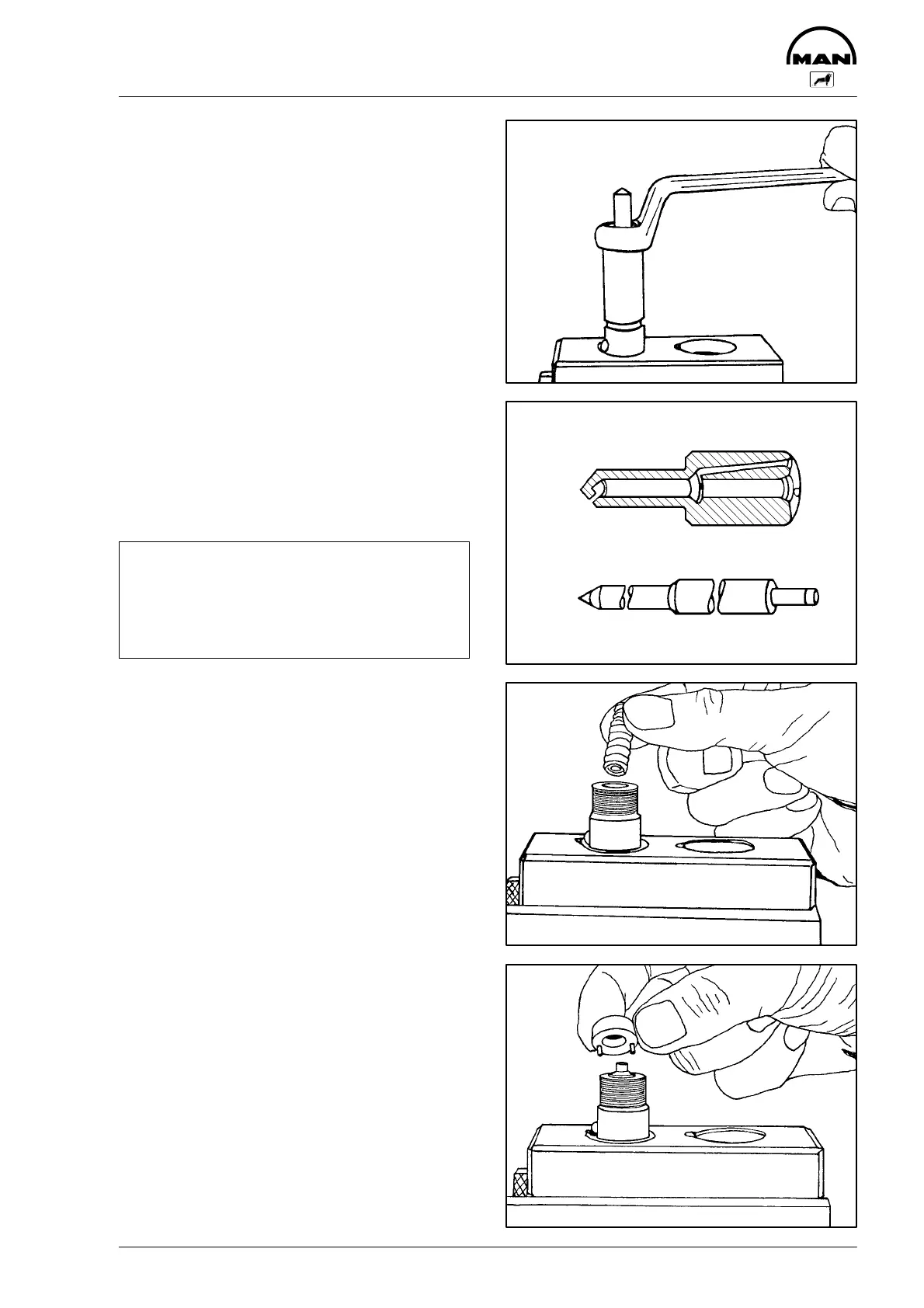

Fig. 3

Insert injector assembly (the inlet orifice facing

downwards) into the clamping device and hold in a

vice. Remove union nut and take out nozzle body,

intermediate washer, pressure pin, compression

spring and shim. Take pressure pipe neck out of

holder.

Repairing fuel injectors

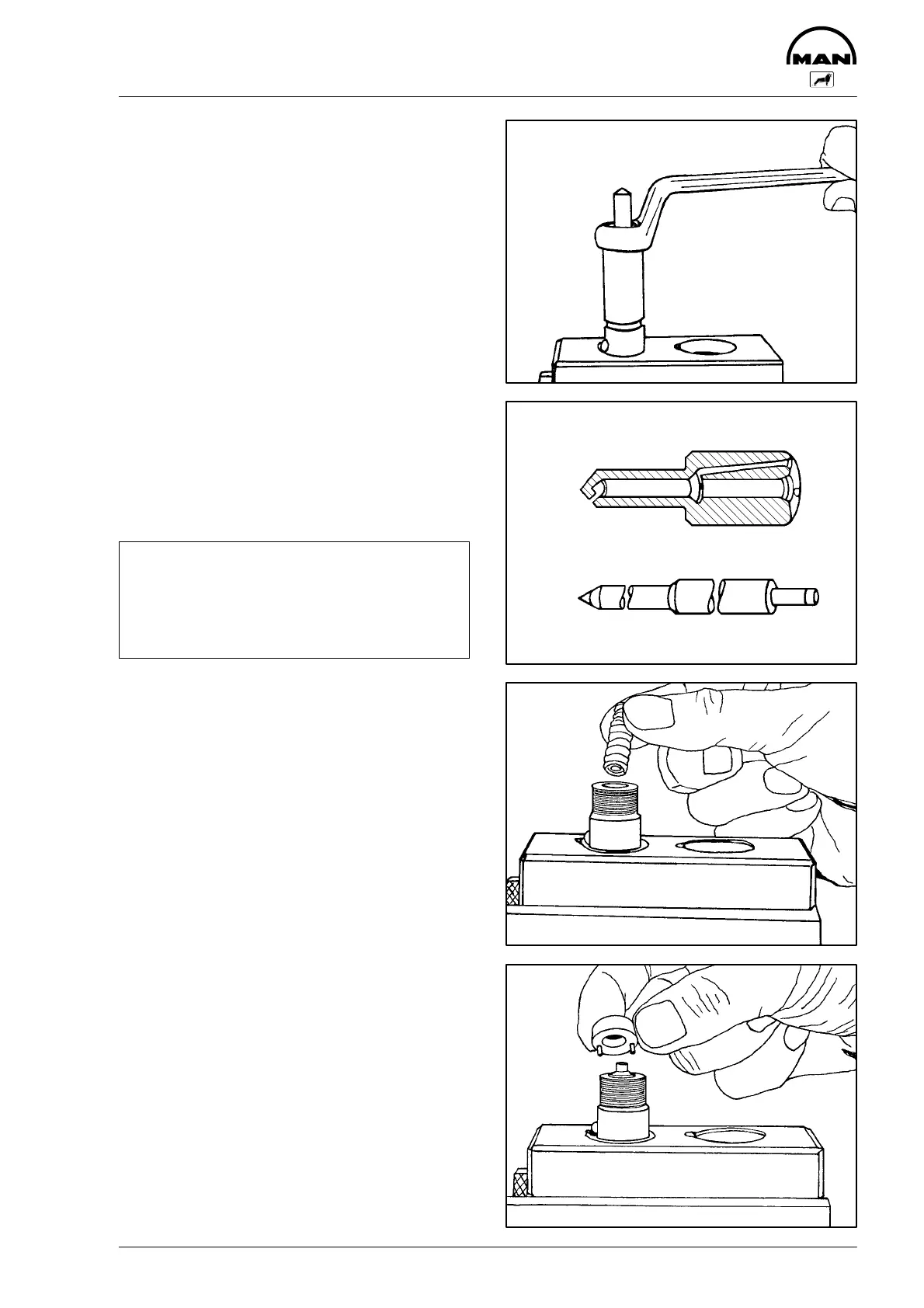

Fig. 4

Clean interior of injection body (1) with a small

wooden stick and petrol or Diesel fuel.

Clean nozzle needle (2) with a clean cloth.

Note:

To prevent corrosion, do not touch lapped

faces of nozzle needle with the fingers. The

needle and injection nozzle are matched to

each other and must not be interchanged.

Check cleaned parts for wear and damage, replac-

ing them if necessary. De-grease new parts.

Assembling fuel injectors

Fig. 5

Insert pressure pipe neck into clamping device.

Insert shim and compression spring.

Fig. 6

Insert pressure pin and intermediate washer.

2645

2646

1

2

2654

2655

Loading...

Loading...