1

2

3

Reworking valve seat

93

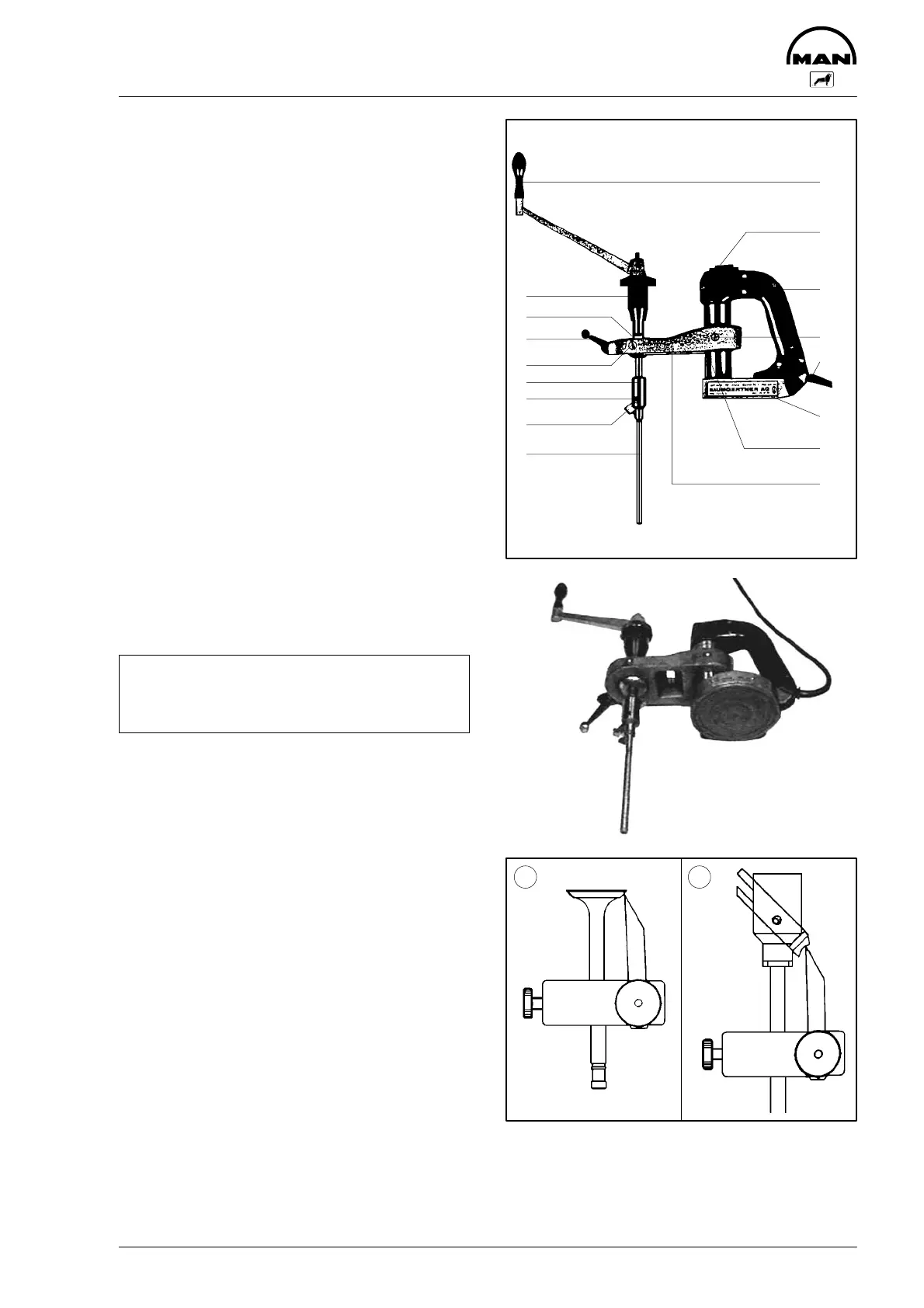

Reworking valve seat

(with Mira precision valve seat machining device)

Fig. 1

1 Feed nut with mm scale

2 Guide ball

3 Jaccard lever

4 Lubricating nipple

5 Rotary head

6 Hex socket screw

7 Tool

8 Guide mandrel

9 Driving crank

10 Toggle switch

11 Handle

12 Lubricating nipple

13 Mains connection

14 Magnetic flange with coil

15 Guide pipe

16 Slewing arm

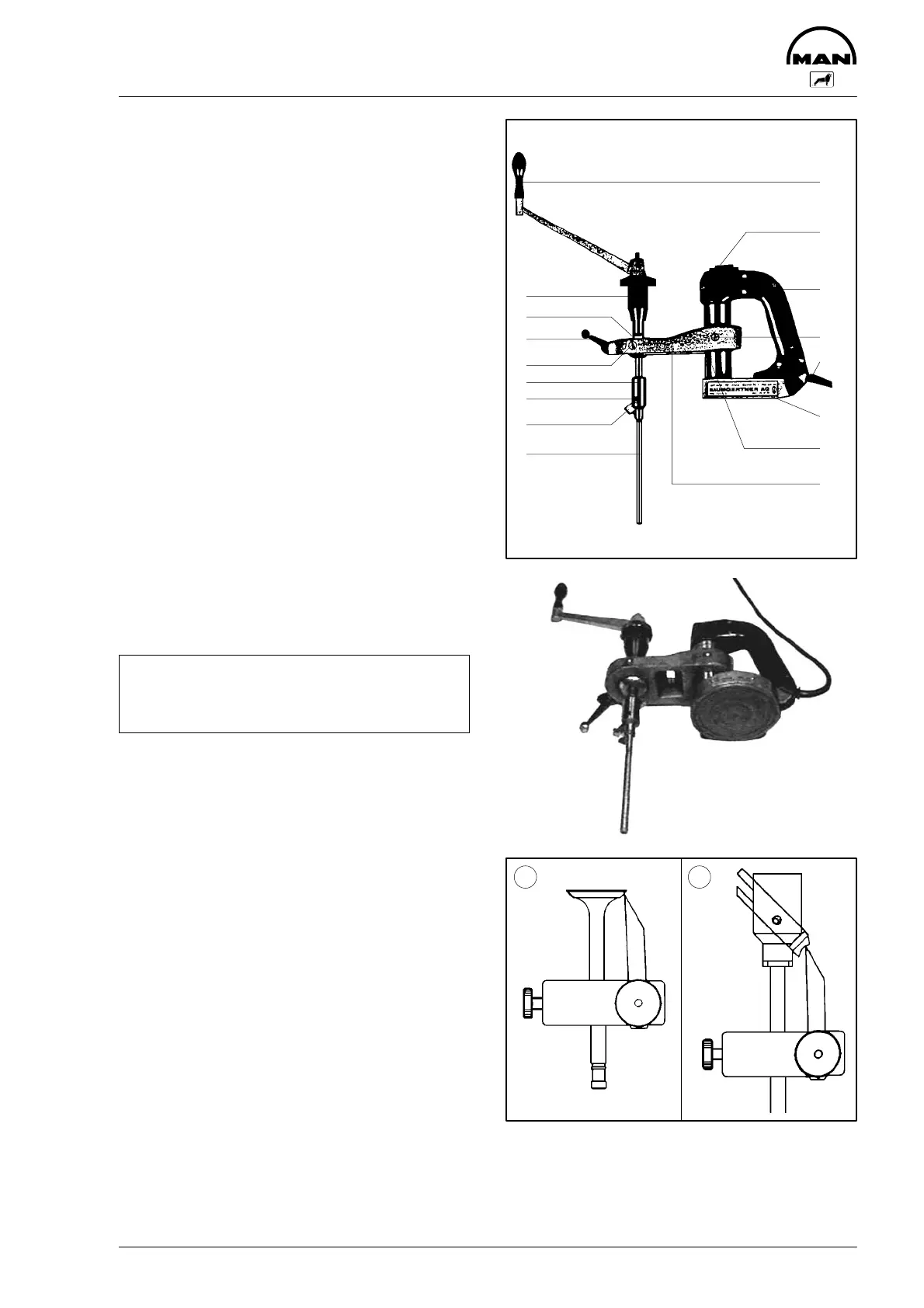

Fig. 2

Select suitable guide mandrel, screw it in with a

spanner (12 mm) and tighten it.

Note:

For extreme precision work the guide man-

drel must fit snugly.

Select and insert the tool with the corresponding

seat width and the corresponding seat angle.

Fig. 3

Set the tool with a setting gauge and tighten it with

the hex socket screw.

Insert unit with guide mandrel into the valve guide.

3358

1

2

3

4

5

6

7

8

10

9

11

12

13

14

15

16

3360

3359

21

Loading...

Loading...