G

G

5

5

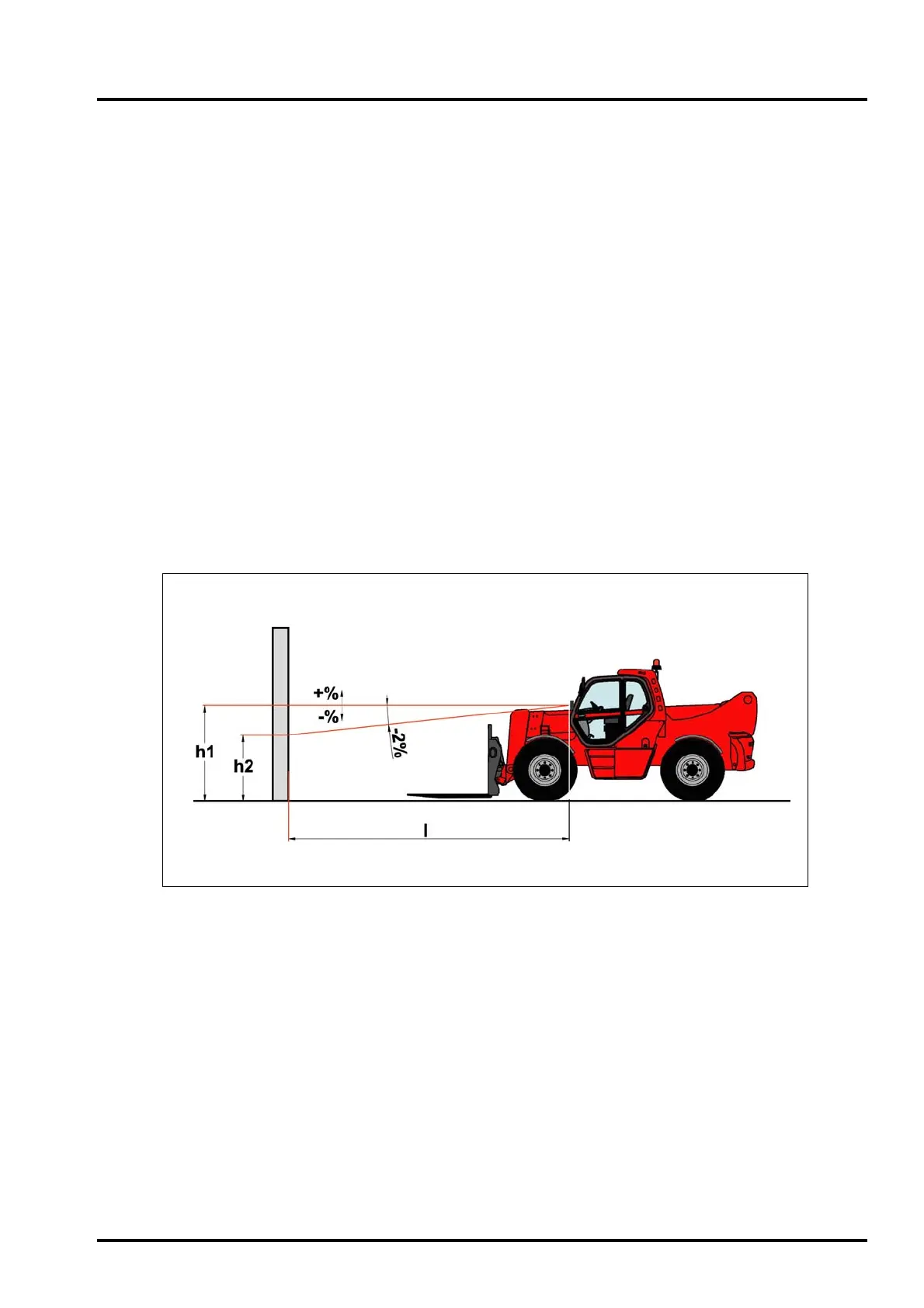

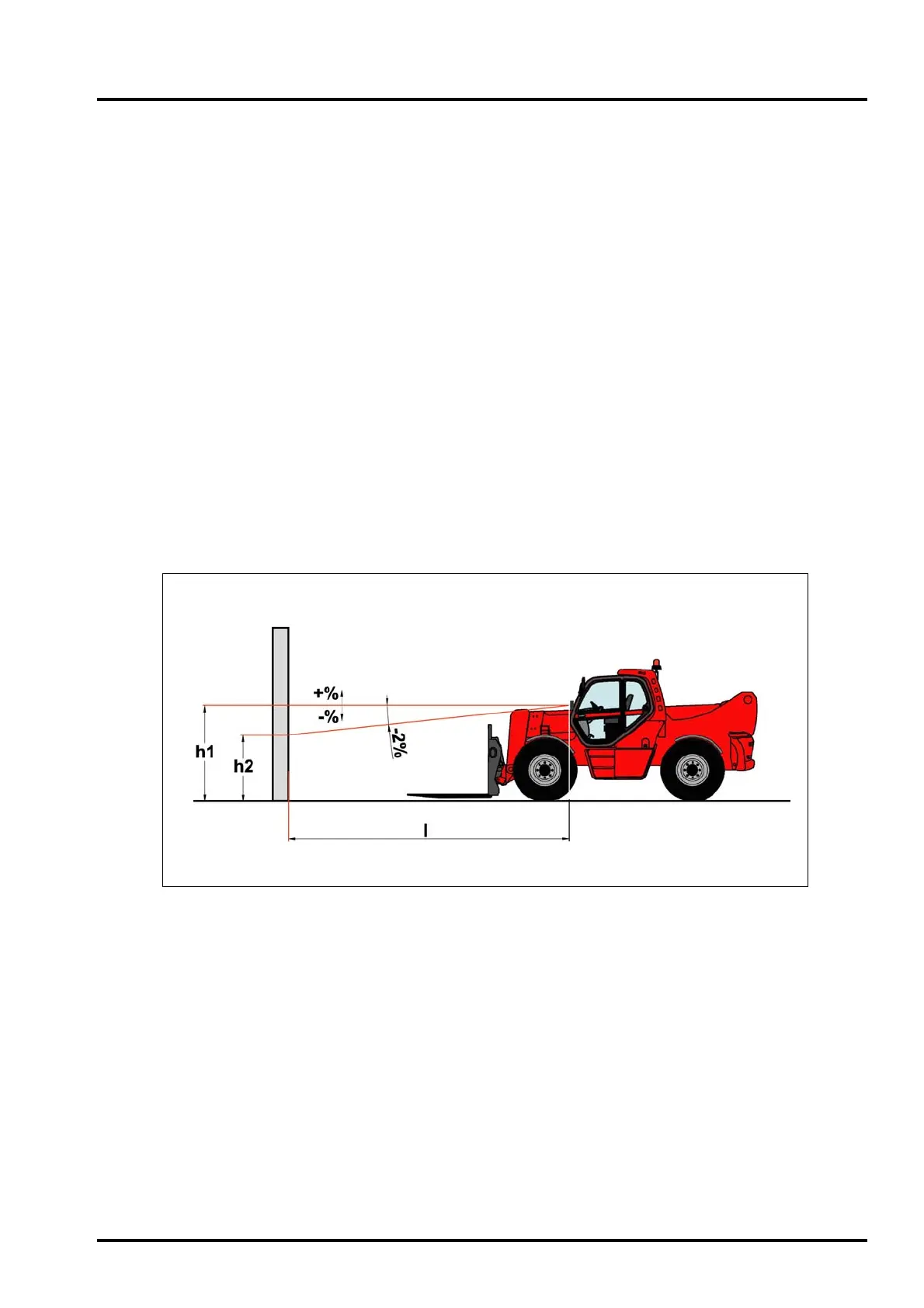

- ADJUST THE FRONT HEADLAMPS

Recommended setting

(As per standard ECE-76/756 76/761 ECE20)

Set to - 2% of the dipped beam in relation to the horizontal line of the headlamp.

Adjusting procedure

- Place the lift truck unloaded and in the transport position and perpendicular to a white wall on flat, level

ground (Fig. G5).

- Check the tyre pressures (See chapter : A4 - CHECK THE TYRE PRESSURES AND THE WHEEL NUTS

TORQUE in paragraph : 3 - MAINTENANCE).

- Put the gear reverser lever in neutral and action the parking brake.

Calculating the height of the dipped beam (h2) (FIG. G5)

h1 = Height of the dipped beam in relation to the ground.

h2 = Height of the adjusted beam.

l = Distance between the dipped beam and the white wall.

h2 = h1- (l x 2/100)

G

G

6

6

- AIR CONDITION

Change the gas if the air is not as cold as desired :

- use “134 FREON” 1 Kg.

- in case of failure or part’s substitution change the oil using 60 gr of specific oil for Air Condition compressor.

Fig. G5

MHT 10120 L M

Series

35

3

Loading...

Loading...