4

1

MHT 10120 L M

SS

eries

ELECTRICAL SYSTEM

Starter motor.

The starter motor is installed on the left of the engine and no maintenance is required except cleaning and

tightening of the terminals. If the starter motor does not work properly, consult your agent or dealer.

Alternator.

The alternator is installed on the left of the motor. The alternator and regulator are designed to operate in a

system polarised in one direction only, so the following precautions must be taken when working on the battery

charging circuit; otherwise, serious damage may be caused to the electrical equipment:

Never operate the alternator with the circuit open; ensure that all terminals are firmly tightened.

It is important not to remove the terminals on the back of the alternator while the engine is running, as this

may damage the alternator itself.

When fitting a battery, check that the connections are correctly polarised. It is essential for the cable marked

(+) to be connected to the positive terminal (+) of the battery and the cable marked (-) to be connected to the

negative terminal (-) on the battery, and that there is a ground connection.

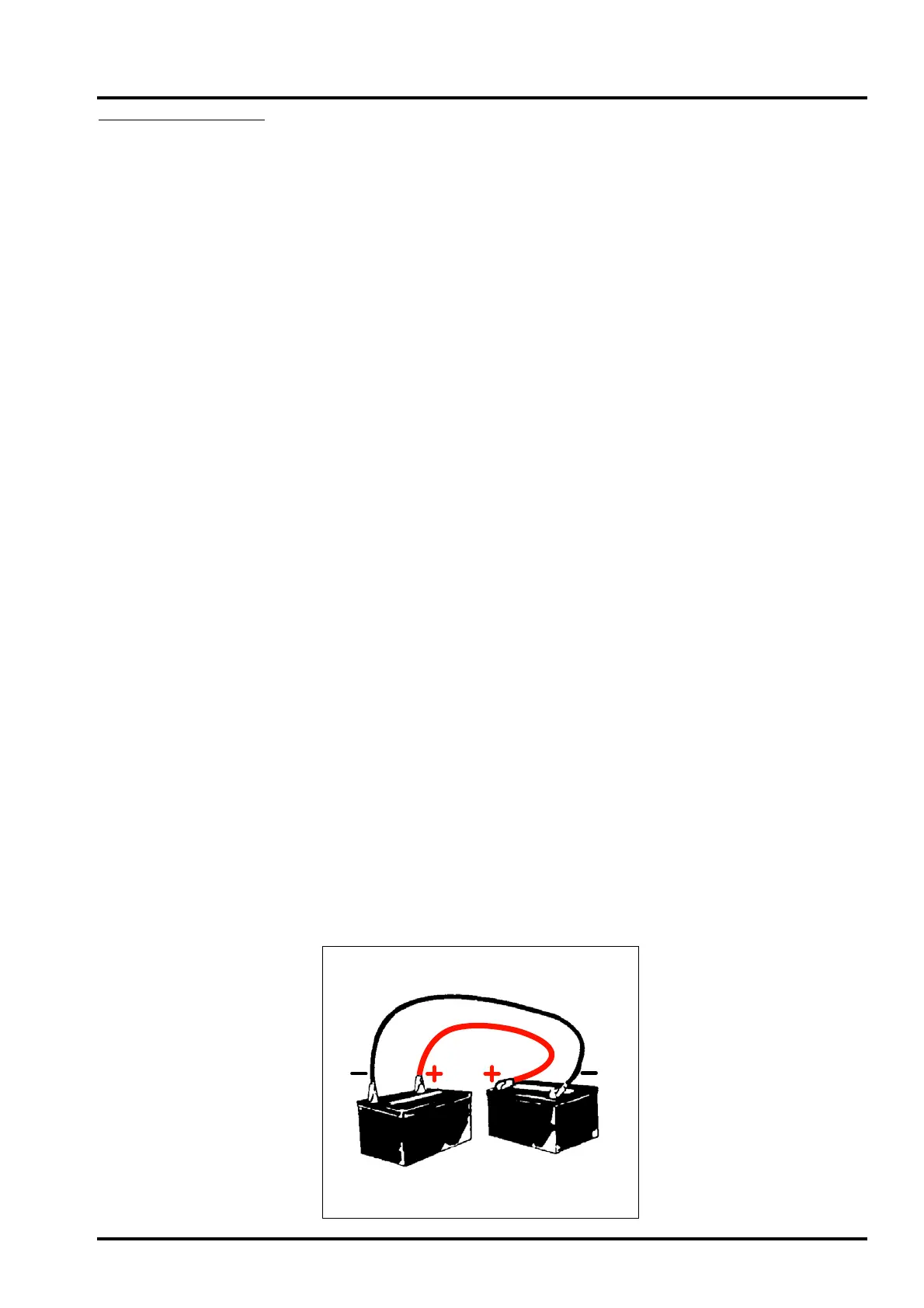

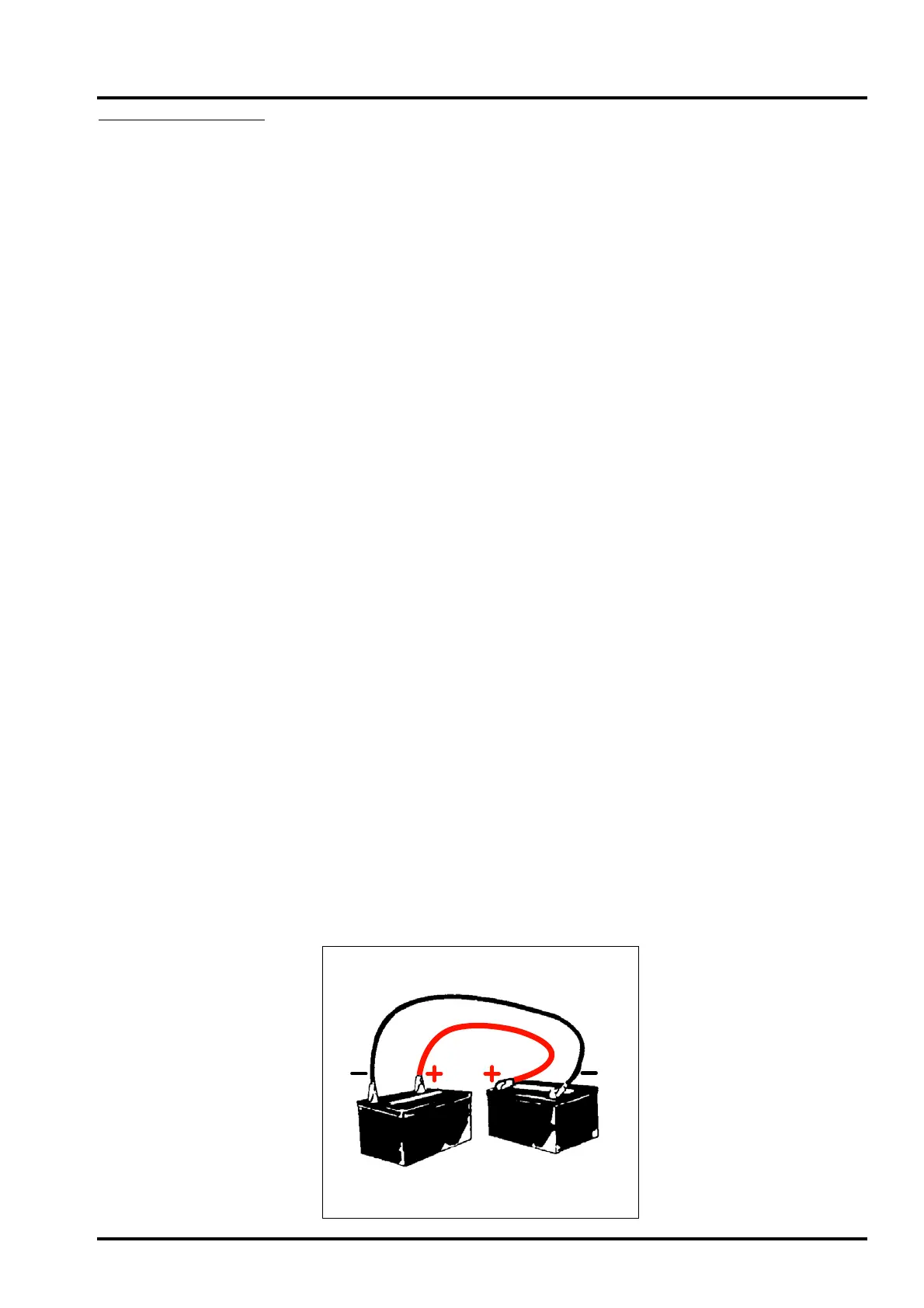

If a second battery is used to start the engine, always connect terminals of the same polarity (Fig. A). Fit a

battery with the same voltage as that installed on the truck.

If an external charger is used, always connect the (+) wire of the charger to the (+) terminal of the battery and

the (-) wire of the charger to the (-) terminal of the battery and ground connection.

Never short-circuit the alternator terminals or connect them to ground.

Never reverse the alternator connection on the battery.

Never remove or replace an electrical connection while the engine is running.

If electric-arc welding is carried out on the truck, directly connect the welder negative wire to the piece to be

welded, to ensure that the high voltage current cannot pass through the alternator, and then disconnect the

battery.

FIG. A

Loading...

Loading...