3 - 223 - 22

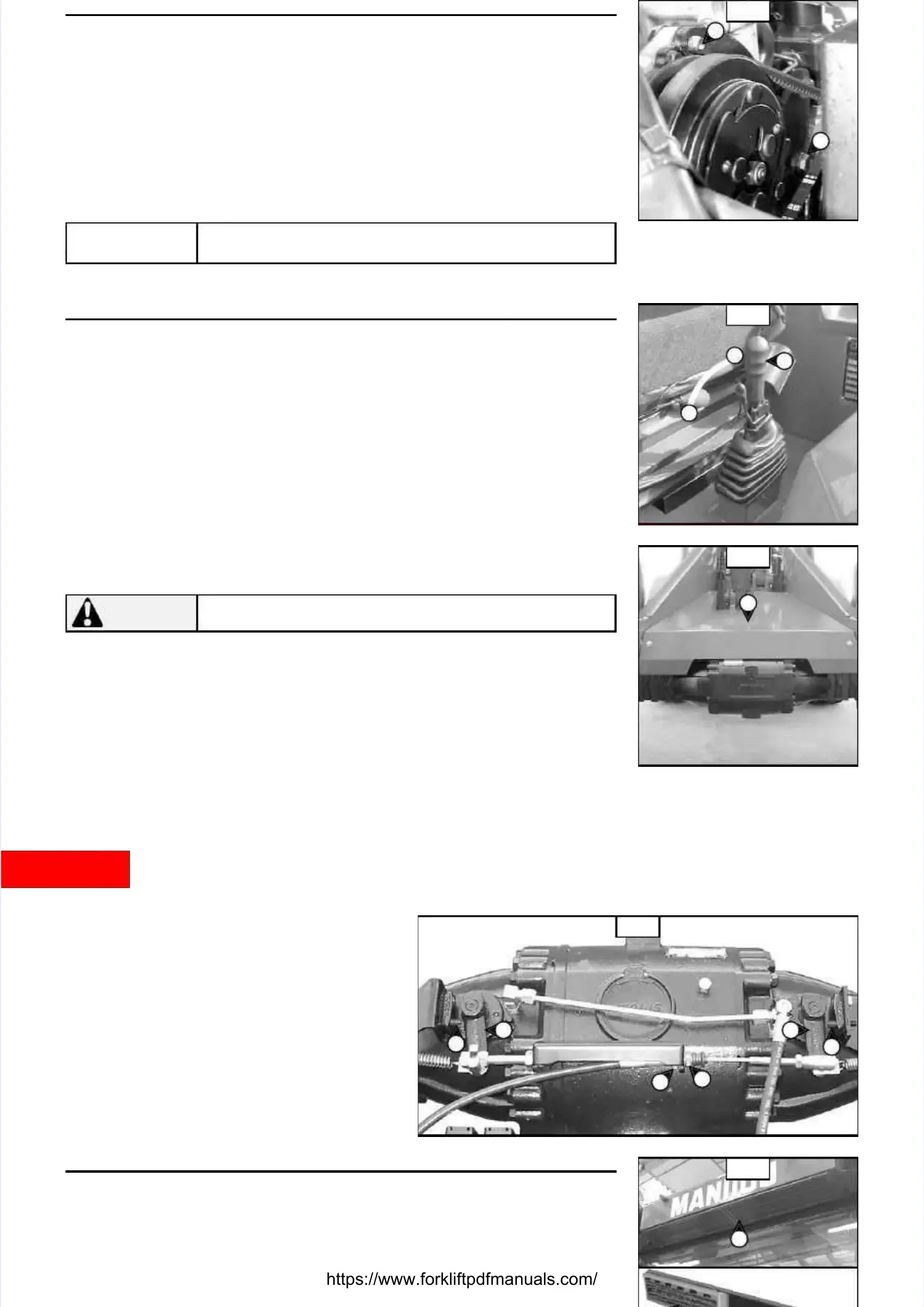

C2 - CC2 - COMOMPRPRESESSOSORR BEBELTLT TETENSNSIOIONN ((OPTOPTIOIONN AAIIRR CONCONDITDITIONIONINGING))

CHECK - ADJUSTCHECK - ADJUST

- Open the I.C. engine cover.- Open the I.C. engine cover.

- Check the belt for signs of wear and cracks and change if necessary (see : 3 - MAINTE-- Check the belt for signs of wear and cracks and change if necessary (see : 3 - MAINTE-

NANCE : FILTERS CARTRIDGES AND BELTS).NANCE : FILTERS CARTRIDGES AND BELTS).

- Check the belt - Check the belt tension between the pulleys of tension between the pulleys of the crankshaft and of the crankshaft and of the compressorthe compressor..

- Under a normal pressure exerted with the thumb (10 ft/lb),- Under a normal pressure exerted with the thumb (10 ft/lb), the tension should be approx-the tension should be approx-

imately 3/8 in.imately 3/8 in.

- Carry out adjustments if necessary.- Carry out adjustments if necessary.

- Loosen screws 1 (fig. C2) by two to three thread turns.- Loosen screws 1 (fig. C2) by two to three thread turns.

- Swivel the compressor assembly so as to obtain the belt tension required.- Swivel the compressor assembly so as to obtain the belt tension required.

- Retighten screws 1 (fig. C2).- Retighten screws 1 (fig. C2).

If the compressor belt has to be changed, check the tension again after the first 20 hours of

If the compressor belt has to be changed, check the tension again after the first 20 hours of

operation.operation.

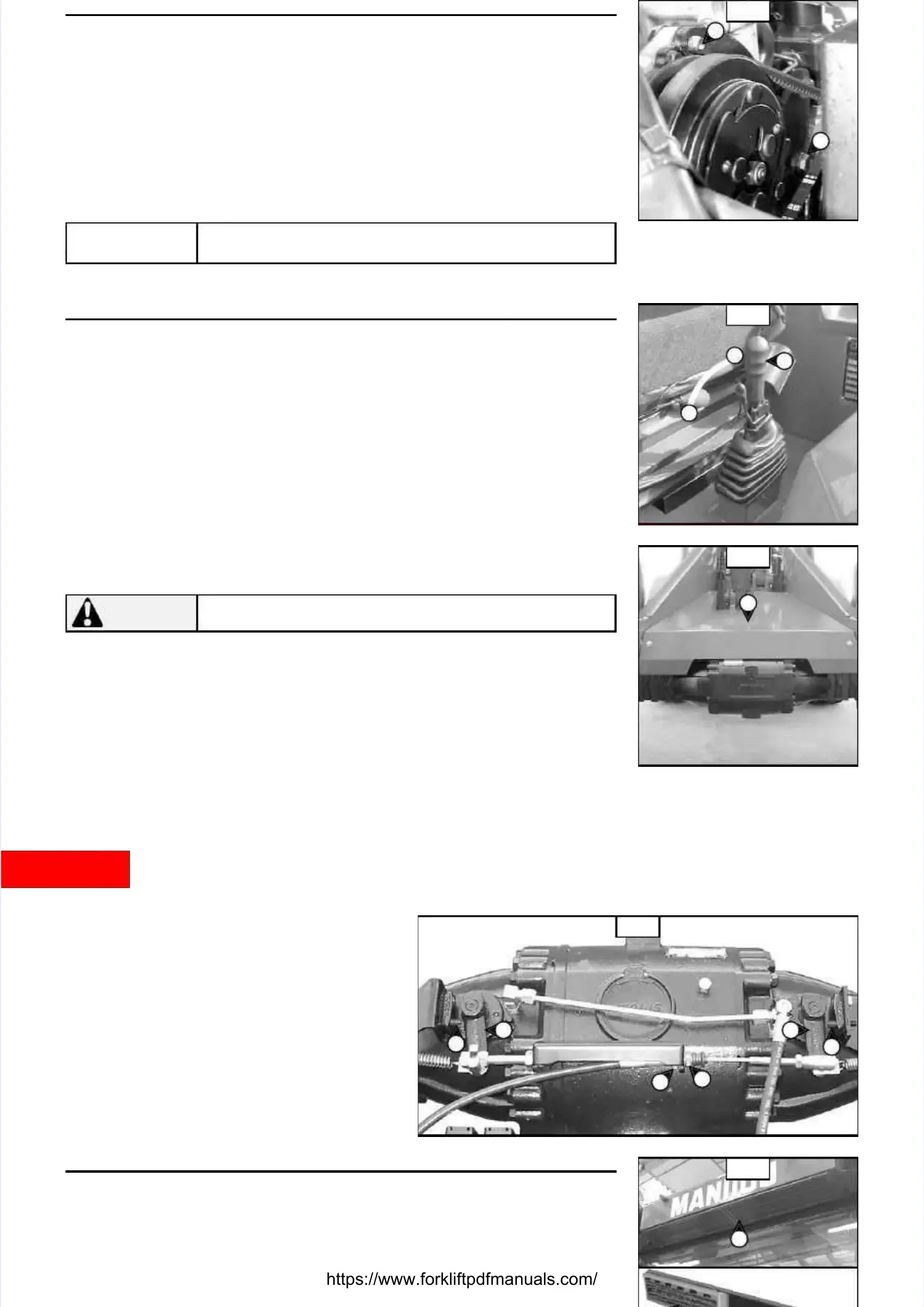

C3 - PC3 - PARKARKINGING BRBRAKAKEE

CHECK - ADJUSTCHECK - ADJUST

Park the lift truck on a slope Park the lift truck on a slope less than 15less than 15 % with the rated load in the % with the rated load in the transport position.transport position.

- Check the tightening adjustment by locking the par- Check the tightening adjustment by locking the parking brake in position A (figking brake in position A (fig. C3/1).. C3/1).

- The adjustment is correct when the lift truck is held stationary on a slope.- The adjustment is correct when the lift truck is held stationary on a slope.

- Carry out - Carry out adjustments if necessary.adjustments if necessary.

ADJUSTMENT OF THE PARKING BRAKE CABLE ON THE FRONT AXLEADJUSTMENT OF THE PARKING BRAKE CABLE ON THE FRONT AXLE

- Pres- Press and release s and release the brake pthe brake pedal,edal, then release the then release the parking brake,parking brake, putting it in posputting it in positionition

B (fig. C3/1).B (fig. C3/1).

- Remove the cover plate 1 (fig. C3/2).- Remove the cover plate 1 (fig. C3/2).

- Unscrew nuts 2 (fig. C3/3).- Unscrew nuts 2 (fig. C3/3).

- - Adjust the cable by loosening nuAdjust the cable by loosening nuts 2 (fig. C3/3),ts 2 (fig. C3/3), until a clearance of 0.06 in. betwuntil a clearance of 0.06 in. betweeneen

cams 3 (fig. C3/3) and stops 4 (fig. cams 3 (fig. C3/3) and stops 4 (fig. C3/3) is obtained.C3/3) is obtained.

The adjustment of the stops performed by the manufacturer must not be modified under any

The adjustment of the stops performed by the manufacturer must not be modified under any

circumstances.circumstances.

ADJUSTMENT OF THE ADJUSTMENT OF THE PARKING BRAKEPARKING BRAKE

- Leave the parking brake in position - Leave the parking brake in position B (fig. C3/1).B (fig. C3/1).

- Progressively tighten the end piece of - Progressively tighten the end piece of the lever 5 (fig. C3/1) and recheck braking.the lever 5 (fig. C3/1) and recheck braking.

- Repeat the operation until the correct - Repeat the operation until the correct braking adjustment is obtained.braking adjustment is obtained.

C3/1C3/1

C3/2C3/2

AA

BB

55

11

C2C2

11

11

If the alternator belt has to be changed, check the tension again after theIf the alternator belt has to be changed, check the tension again after the

first 20 hours of operation.first 20 hours of operation.

IMPORTANTIMPORTANT

Make adjustments only to the stops noted. DO NOT MAKE ADJUSTMENTSMake adjustments only to the stops noted. DO NOT MAKE ADJUSTMENTS

TO THE DRIVE AXLE FACTOTO THE DRIVE AXLE FACTORY SETTINGS! RY SETTINGS! (CONTACT YOUR DEALER.(CONTACT YOUR DEALER.))

WARNINGWARNING

Loading...

Loading...