3 - 233 - 23

C5 - FC5 - F

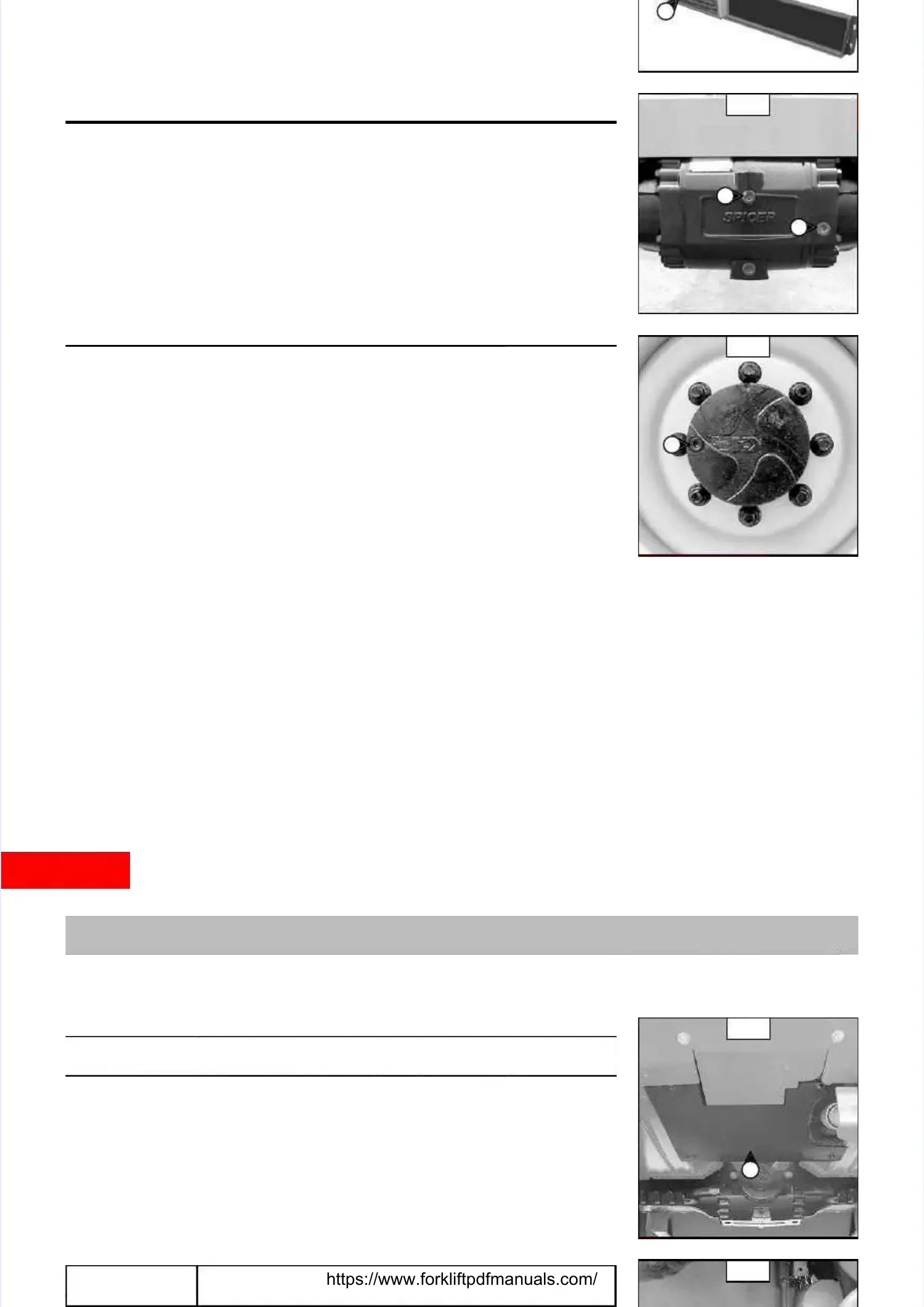

RORONTNT AANDND RREEAARR AAXXLLEE DDIIFFFFEERERENNTITIAALL OIOILL LELEVEVELL

CHECKCHECK

Park the lift truck on level ground with the I.C. engine stopped.Park the lift truck on level ground with the I.C. engine stopped.

- Remove level plug 1 (fig. C5). The oil should be flush with the edge of the hole.- Remove level plug 1 (fig. C5). The oil should be flush with the edge of the hole.

- If neces- If necessary,sary, add oil (see : add oil (see : 3 - MAINTENANCE3 - MAINTENANCE : LUBRICANTS : LUBRICANTS AND FUEL) by AND FUEL) by the filler portthe filler port

2 (fig. C5).2 (fig. C5).

- Replace and tighten the level plug 1 (fig. C5) (tightening torque 32 ft/lb).- Replace and tighten the level plug 1 (fig. C5) (tightening torque 32 ft/lb).

- Repeat this operation for the rear axle differential.- Repeat this operation for the rear axle differential.

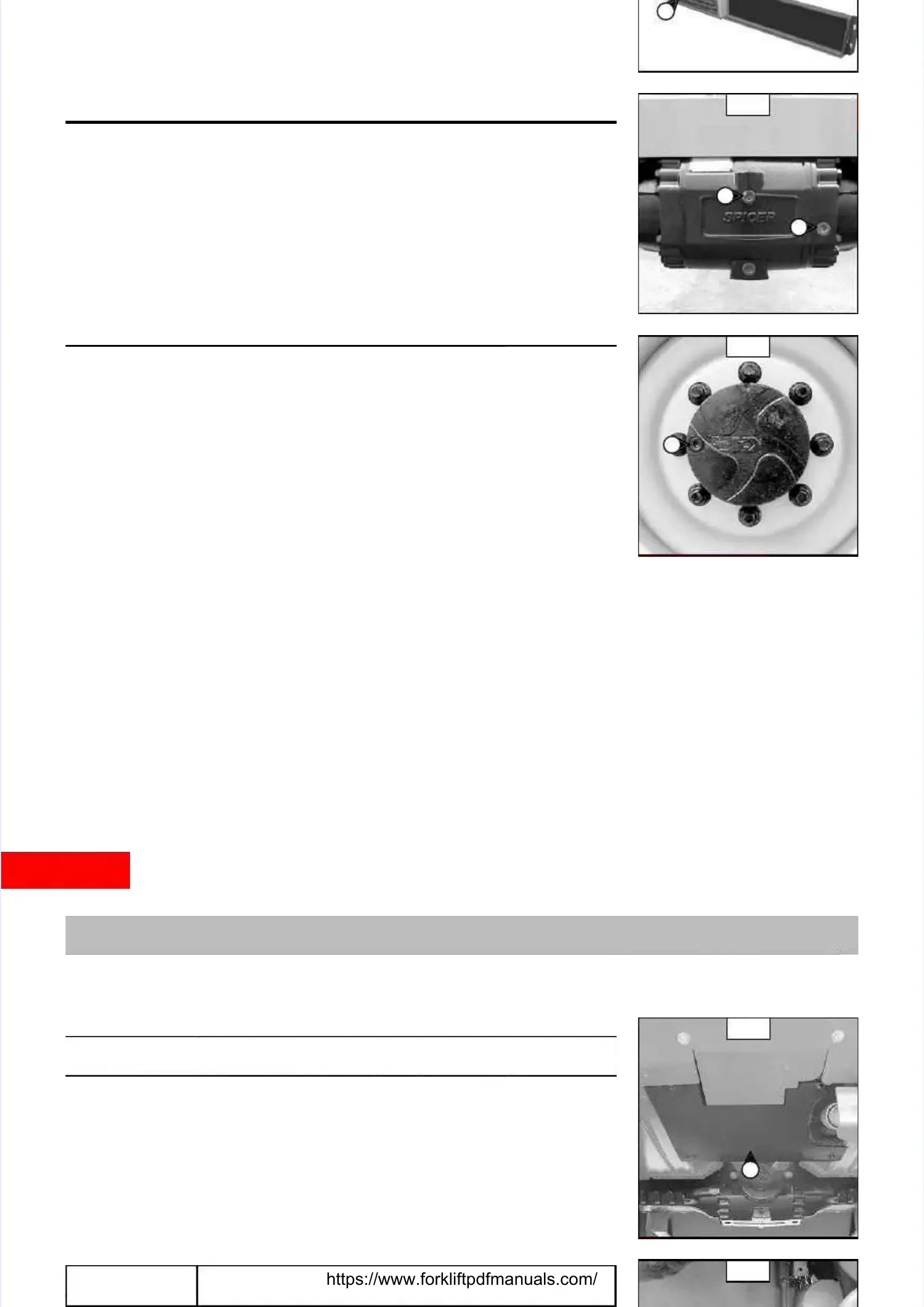

C6 - FC6 - FRROONNTT AANNDD RREEAARR WWHHEEEELSLS RREDEDUCUCEERSRS OOILIL LLEEVEVELL

CHECKCHECK

Park the lift truck on level ground with the I.C. engine stopped.Park the lift truck on level ground with the I.C. engine stopped.

- Check the level - Check the level on each front wheel on each front wheel reducerreducer..

- Place level plug 1 (fig. C6) in the horizontal position.- Place level plug 1 (fig. C6) in the horizontal position.

- Remove the le- Remove the level plugvel plug ; the oil should be flus; the oil should be flush with the edge of the hole.h with the edge of the hole.

- If necessary,- If necessary, add oil (see : add oil (see : 3 - MAINTENANCE3 - MAINTENANCE : LUBRICANTS : LUBRICANTS AND FUEL) by AND FUEL) by the same hole.the same hole.

- Replace and tighten the level plug 1 (fig. C6) (tightening torque 32 ft/lb).- Replace and tighten the level plug 1 (fig. C6) (tightening torque 32 ft/lb).

- Repeat the same - Repeat the same operation on each rear operation on each rear wheel reducerwheel reducer..

22

C5C5

C6C6

11

11

22

D - EVERY 500 HOURS SERVICED - EVERY 500 HOURS SERVICE

Carry out the operations described previously as well as the following operations.

Carry out the operations described previously as well as the following operations.

D1 - I.C.D1 - I.C. ENENGIGINENE OIOILL

DRAINDRAIN

D2 - I.C.D2 - I.C. ENENGIGINENE OIOILL FFIILLTTEERR

CHANGECHANGE

Park the lift trucPark the lift truck on level groundk on level ground,, let the I.C. enlet the I.C. engine run at idle for a few minutegine run at idle for a few minutes,s, thenthen

stop the I.C. engine.stop the I.C. engine.

DRAINING THE OILDRAINING THE OIL

- Open the I.C. engine cover.- Open the I.C. engine cover.

- Remove access panel 1 (fig. D1/1).- Remove access panel 1 (fig. D1/1).

- Place a container under drain plugs 2 (fig. D1/2) and under the oil filter 3 (fig. D1/2).- Place a container under drain plugs 2 (fig. D1/2) and under the oil filter 3 (fig. D1/2).

- Unscrew the drain plugs 2 (fig. D1/2).- Unscrew the drain plugs 2 (fig. D1/2).

- Remove filler cap 4 (fig. D1/3) in order to ensure that the oil is drained properly.- Remove filler cap 4 (fig. D1/3) in order to ensure that the oil is drained properly.

Dispose of the drain oil in an ecological manner.

Dispose of the drain oil in an ecological manner.

D1/1D1/1

D1/2D1/2

11

Dispose of the drain oil in an ecological manner.Dispose of the drain oil in an ecological manner.

IMPORTANTIMPORTANT

CONTENTSCONTENTS

https://www.forkliftpdfmanuals.com/

Loading...

Loading...