3 - 133 - 13

AND FUEL) by the filler port 3 (fig. A5/1).AND FUEL) by the filler port 3 (fig. A5/1).

NOTENOTE : COLD LEVEL (b: COLD LEVEL (betweetween 59°F and 68°en 59°F and 68°F)F)

The oil must be at its minimum,The oil must be at its minimum, at the level of the scat the level of the screw 1 (fig. A5/1)rew 1 (fig. A5/1)

HOT LEVEL (between 180°F and 200°F)HOT LEVEL (between 180°F and 200°F)

The oil must be at the level of the screw 4 (fig. A5/1).The oil must be at the level of the screw 4 (fig. A5/1).

A6 - TA6 - TIIRREESS PRPREESSSSURUREE AANNDD WWHHEEEELL NUNUTSTS TTOORQRQUUEE

CHECKCHECK

- Chec- Check the condk the condition of tition of the tireshe tires,, to detecto detect cuts,t cuts, wearwear,, etc.etc.

- Check the torque load of the wheel nuts. Non compliance with this instruction can cause damage and rupture to the wheel - Check the torque load of the wheel nuts. Non compliance with this instruction can cause damage and rupture to the wheel boltsbolts

and distortion to the wheels.and distortion to the wheels.

Wheel nuts tightening torqueWheel nuts tightening torque

• Fro• Front tiresnt tires : 465 ft/: 465 ft/lblb

• Rear • Rear tirestires : 465 ft: 465 ft/lb/lb

- Check and adjust the tire pressures if necessary (see : 2 - DESCRIPTION- Check and adjust the tire pressures if necessary (see : 2 - DESCRIPTION : CHARACTERISTICS: CHARACTERISTICS).).

Check that the air hose is correctly connected to the tire valve before inflating and keep all persons at a distance during inflation. Respect

Check that the air hose is correctly connected to the tire valve before inflating and keep all persons at a distance during inflation. Respect

the recommended tire pressures given.the recommended tire pressures given.

A5/2A5/2

44

11

22

Check that the air hose is correctly connected to the tire valve before inflating and keep all persons at a distance dur-Check that the air hose is correctly connected to the tire valve before inflating and keep all persons at a distance dur-

ing inflation. Respect the recommended tire pressures given.ing inflation. Respect the recommended tire pressures given.

WARNINGWARNING

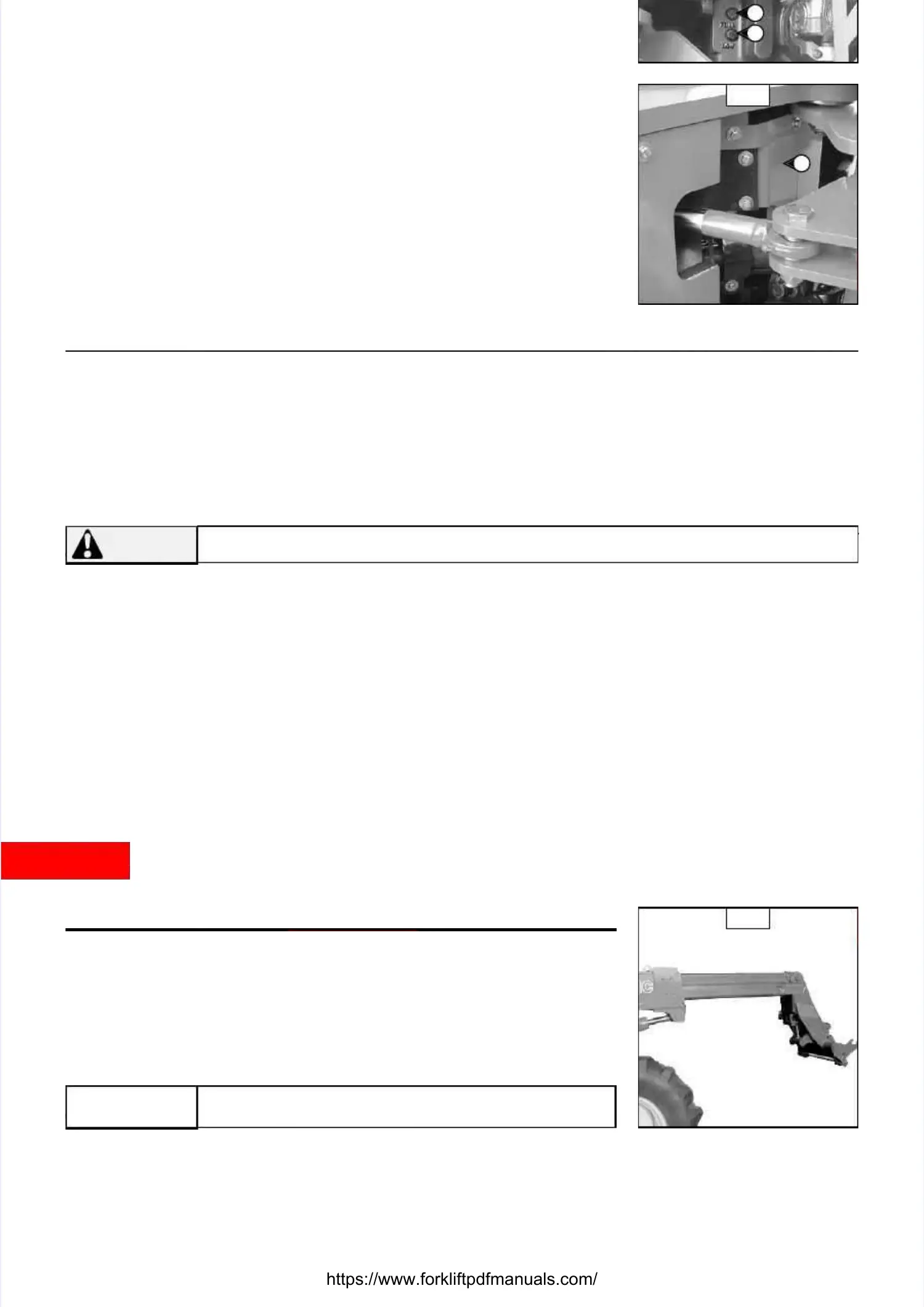

A7 - BA7 - BOOOOMM PPAADDSS

CLEAN - GREASECLEAN - GREASE

TTo be carried out every 10 hours during the first 50 hours service,o be carried out every 10 hours during the first 50 hours service, then once at 250 hours.then once at 250 hours.

- Extend the - Extend the boom completely.boom completely.

- With a - With a brush,brush, apply a coat apply a coat of grease of grease (see : 3 (see : 3 - MAINTENANCE- MAINTENANCE : LUBRICANTS : LUBRICANTS AND FUEL)AND FUEL)

on the 4 sides of the telescope(s) (fig. A7).on the 4 sides of the telescope(s) (fig. A7).

- Teles- Telescope the boom cope the boom several times in several times in order to spread the order to spread the coat of grease evenly.coat of grease evenly.

- Remove the surplus of grease.- Remove the surplus of grease.

If the lift truck is used in an abrasive environment (dust, sand, coal…) Use lubricating varnish

If the lift truck is used in an abrasive environment (dust, sand, coal…) Use lubricating varnish

(MANI(MANITOU refTOU referenceerence : 483536). In this : 483536). In this respect, consult your dealer.respect, consult your dealer.

A7A7

If the lift truck is used in an abrasive environment (dust, sand, coal…) UseIf the lift truck is used in an abrasive environment (dust, sand, coal…) Use

lubricating varnish, contact your dealer.lubricating varnish, contact your dealer.

IMPORTANTIMPORTANT

CONTENTSCONTENTS

Loading...

Loading...