36 Part Number 000014141 Rev 11 12/23

Installation Section 2

Design & Burst Pressure

Design Pressure 600 psig - 4137 kPa

Burst Pressure 2500 psig - 17237 kPa

Head Pressure Control Valve

Do not use a fan cycling control to try to

maintain discharge pressure. Compressor

failure will result. Any remote condenser

connected to a Manitowoc Ice Machine

must have the OEM head pressure control

valve installed. Manitowoc will not accept

substitute “off the shelf” head pressure

control valves.

Kits are available for head pressure control

installation:

• R404A Refrigerant - K00479

• R410A Refrigerant - K00221

Fan Motor

The condenser fan must be on during the

complete ice machine freeze cycle (do

not cycle on fan cycle control). The ice

maker has a condenser fan motor circuit

for use with a Manitowoc condenser. It is

recommended that this circuit be used to

control the condenser fan(s) on the multi-

circuit condenser to assure it is on at the

proper time. Do not exceed the rated amps

for the fan motor circuit listed on the ice

machine’s serial tag.

Internal Condenser Volume

The multi-circuit condenser internal

volume must not be less than or exceed

that used by Manitowoc. Do not exceed

internal volume and try to add charge to

compensate, as compressor failure will

result.

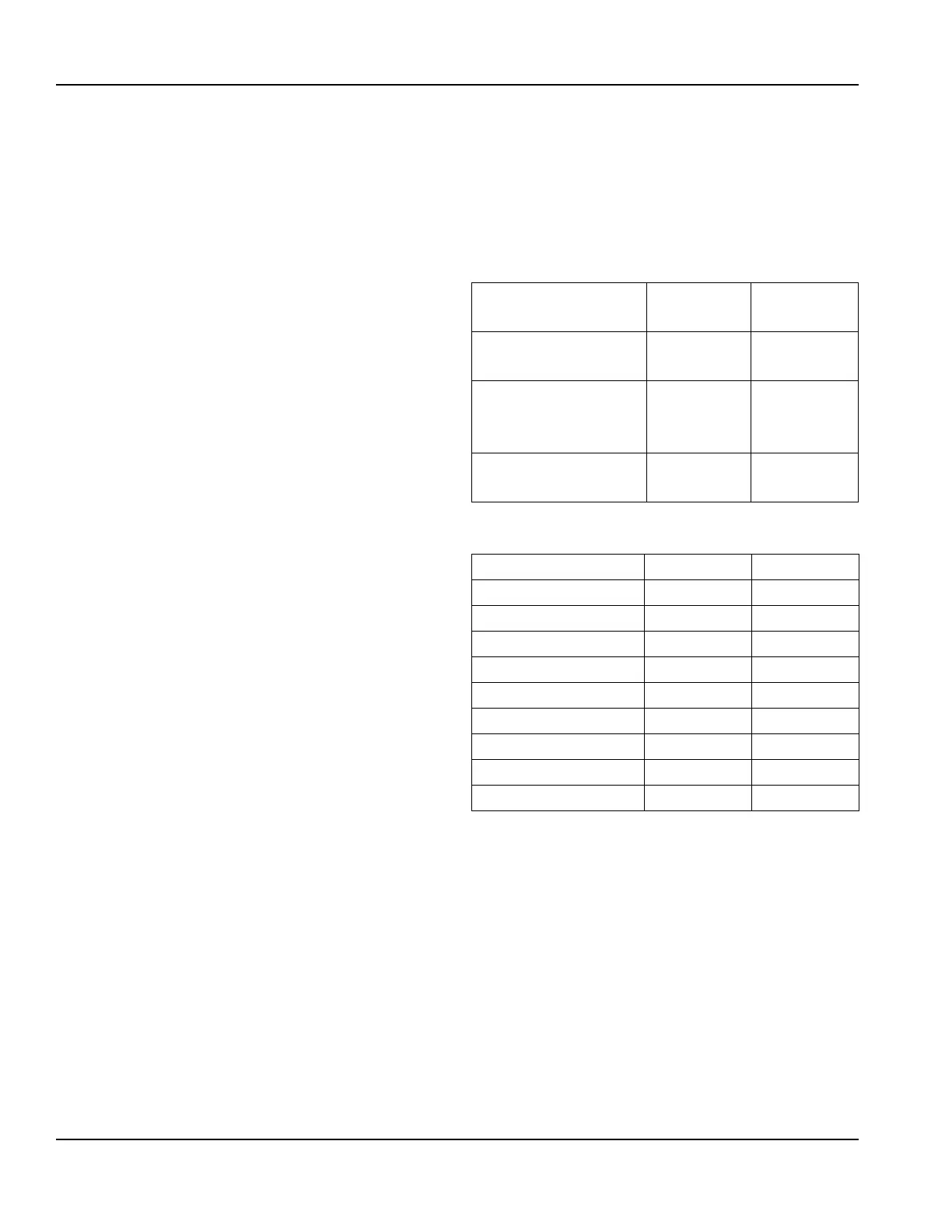

Model

Minimum

ft

3

(cm

3

)

Maximum

ft

3

(cm

3

)

IT0500N

IF0500N

0.020

(566)

0.030

(850)

IF0600N/IF0900N

IT0750N/IT0900N/

IT1200N

0.045

(1274)

0.060

(1699)

IT1500N/IT1900N

0.085

(2407)

0.105

(2973)

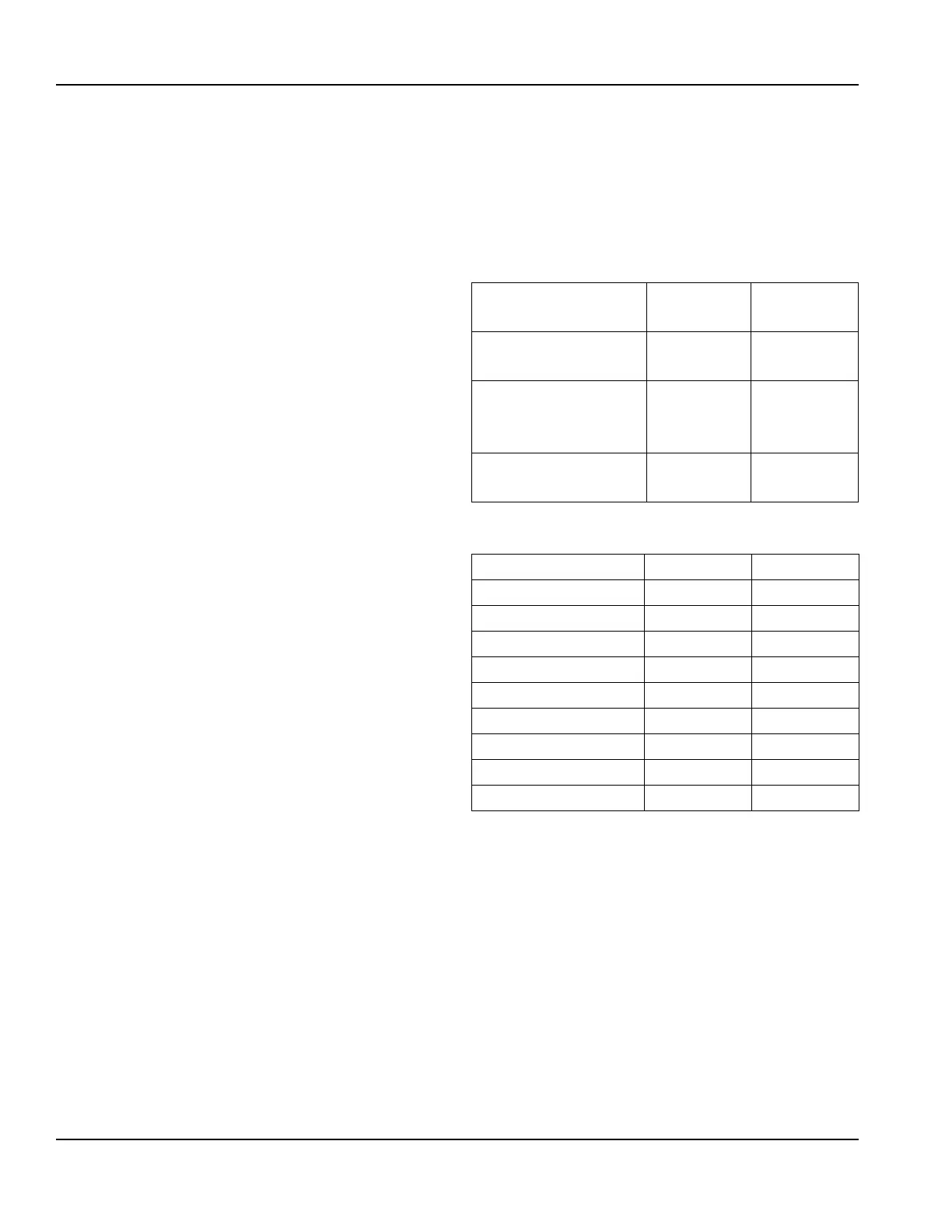

Heat of Rejection

Model Peak Average

IF0500N 6900 6100

IT0500N 6900 6100

IF0600N 13900 9000

IT0750N 13700 12800

IF0900N 16000 13000

IT0900N 16000 13000

IT1200N 24500 20700

IT1500N 27000 23000

IT1900N 30500 26100

Loading...

Loading...