OPERATING CONTROLS AND PROCEDURES OPERATOR MANUAL 500E2

3-8 Published 07-26-2019 Control # 111-06

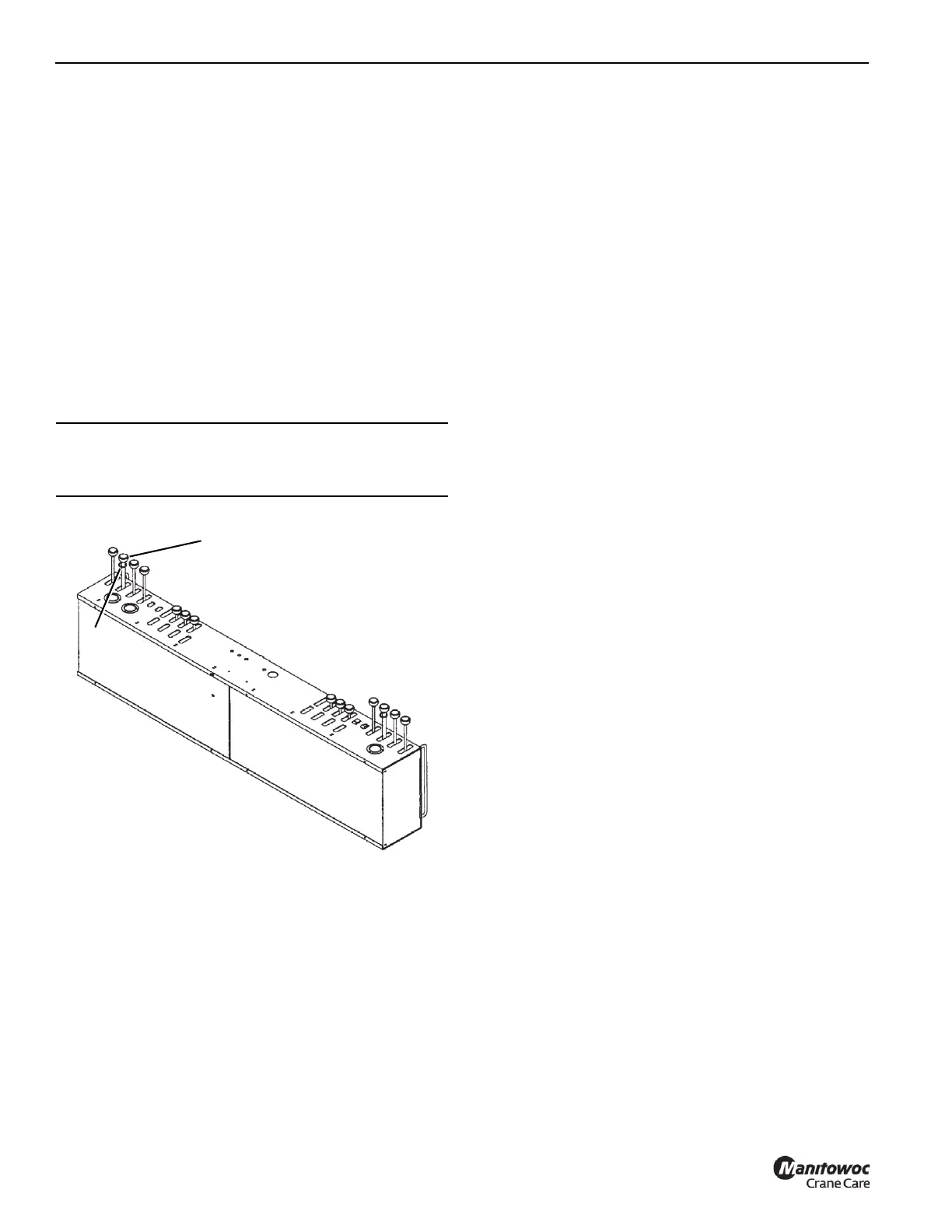

OPTIONAL HOIST BURST OF SPEED (BOS)

The “Burst of Speed” increases hoist line speed 50% over

normal operation by diverting oil from the multi-bank control

valve to the hoist valve.

The “BOS” is engaged by operating the hoist control valve

lever while pulling up on the BOS handle below the hoist

knob. The “BOS” feature should only be operated in a

temporary manner to reduce oil heat build up, prevent truck

PTO overloading, and provide independent operation of the

crane and hoist (normal hoist speed will not decrease when

crane functions are used). If the “BOS” feature is run

continuously or with an overload, damage to the crane or

truck could occur. To start the “BOS” smoothly, first pull up on

the BOS handle then operate the hoist lever. To stop the

“BOS” smoothly, return the hoist lever to its neutral position

then release the BOS handle.

.

ANTI-TWO BLOCK SYSTEM

With untrained or inexperienced or distracted operators, two

blocking the hoist cable is a very real possibility. When the

hoist cable and end attachments contact the underside of the

sheave case, whether by hoisting up or extending the boom

without paying out the hoist cable, the hoist cable can be

damaged by crimping or over tensioning.

The anti-two-block system provided on your National Crane

can help prevent cable damage by sensing the position of

the hoist cable end attachments with respect to the sheave

case and disabling the functions that can cause a two block

condition.

The anti-two-block system consists of normally open, work

port unloader valves in the main and hoist control valves.

When the cartridge solenoid is energized, the crane

functions normally, when de-energized, the oil to the boom

extend, boom down, and hoist up crane functions are

diverted to tank. These solenoids are controlled by a limit

switch, which is attached to the boom or jib sheave case.

This switch is held in the closed position by a chain

suspended weight. The weight, which is looped around the

hoist cable, causes the contacts to remain closed until the

hoist cable end attachments contact the weight and release

the tension on the switch. At this point the contacts in the

switch open, breaking electrical continuity through the circuit

provided by the internal anti-two-block cord routed through

the boom. When this continuity is broken, the unloader

cartridges de-energize and divert the function oil to tank. An

indicator light is provided on the control console to alert the

operator when a two-block condition is detected.

On machines equipped with an optional Rated Capacity

Limiter (RCL) System, the anti-two-block system is integral

with the RCL wiring and display. An audible, visual warning

of the two block condition is provided in the display console.

See RCL Operators Handbook for additional information.

Normal functioning is restored by hoisting down (or retracting

boom) until the weight is once again suspended freely.

Occasionally if the hoist up and boom extend functions are

operated at maximum speed in the dump mode, the back

pressure induced in the circuit will cause the hoist up or

boom extend functions to creep slightly (with no load on the

hook). Such a condition is not cause for alarm, as the back

pressure is not of sufficient magnitude to damage the cable

or end connections.

OUTRIGGER MONITORING SYSTEM (OMS)

(OPTIONAL—STANDARD IN NORTH

AMERICA)

The Outrigger Monitoring System (OMS) aids the operator in

ensuring that the crane is properly setup on outriggers and

stabilizers. The OMS utilizes one sensor in each outrigger

and one proximity switch in each horizontally extending

stabilizer to identify when the outriggers and stabilizer beams

are extended to a point in which they provide maximum

stability.

CAUTION

If the BOS feature Is run continuously or with an overload,

damage to the crane or truck could occur.

BOS

Handle

Note: Maximum Capacity with “BOS”

• One Part Line - 3000 lb (1361 kg)

• Two Part Line - 6000 lb (2722 kg)

• Three Part Line - 9000 lb (4082 kg)

• Maximum line speed on third layer - 271 FPM

(73mpm), fourth layer - 294 FPM (81 mpm)

Hoist Lever

Loading...

Loading...