SET-UP OPERATOR MANUAL 500E2

4-12 Published 07-26-2019 Control # 111-06

Jib Jack Procedures

The Jib Pin alignment device (Jib Jack) is an aid for installing

the fourth or “last” jib pin when setting up a jib. This device

has been designed to line up the bottom jib pin hole on the

left side of the crane the hole in the boom ear.

The jib pin alignment device consists of a hydraulic jack

mounted horizontally on the underside of the jib. A handle for

the jack is provided and is installed above the jack on the

side of the jib.

Prior to using the Jib Jack, complete Steps 1 to 12 in the

“Side Folding-Swing Around Deployment Procedure”.

1. Remove jack handle and using the flattened end, close

jack release valve by turning the handle clockwise until it

is firmly closed.

2. Insert the round end of the handle into the handle sleeve

and pump jack until ram contacts boom sheave case.

3. Continue to pump slowly until jib pin holes exactly

aligned with hole in boom ear. At this time the final jib pin

can be easily tapped into position.

If hole alignment is “over shot” due to jacking too far, the

jack can simply be relieved and the process repeated.

To relieve the jack, use the flattened end of jack handle

to slowly turn relief valve counter clockwise no more

than one full turn.

4. After all jib pins are installed, relieve jack.

The jib pin alignment device is also useful when removing

the “fourth” pin. Use the jib jack to relieve jib weight induced

pressure on the “fourth” pin and it will be much easier to

remove.

Once the jib has been erected or stowed, it is important that

the jack handle be properly placed back on its stowage

hooks and that the cotter key be properly placed in the

stowage hook to retain the handle on the hook.

When Jib is stowed on side of crane, always leave ram and

handle sleeve pushed all the way down to reduce exposure

to rusting.

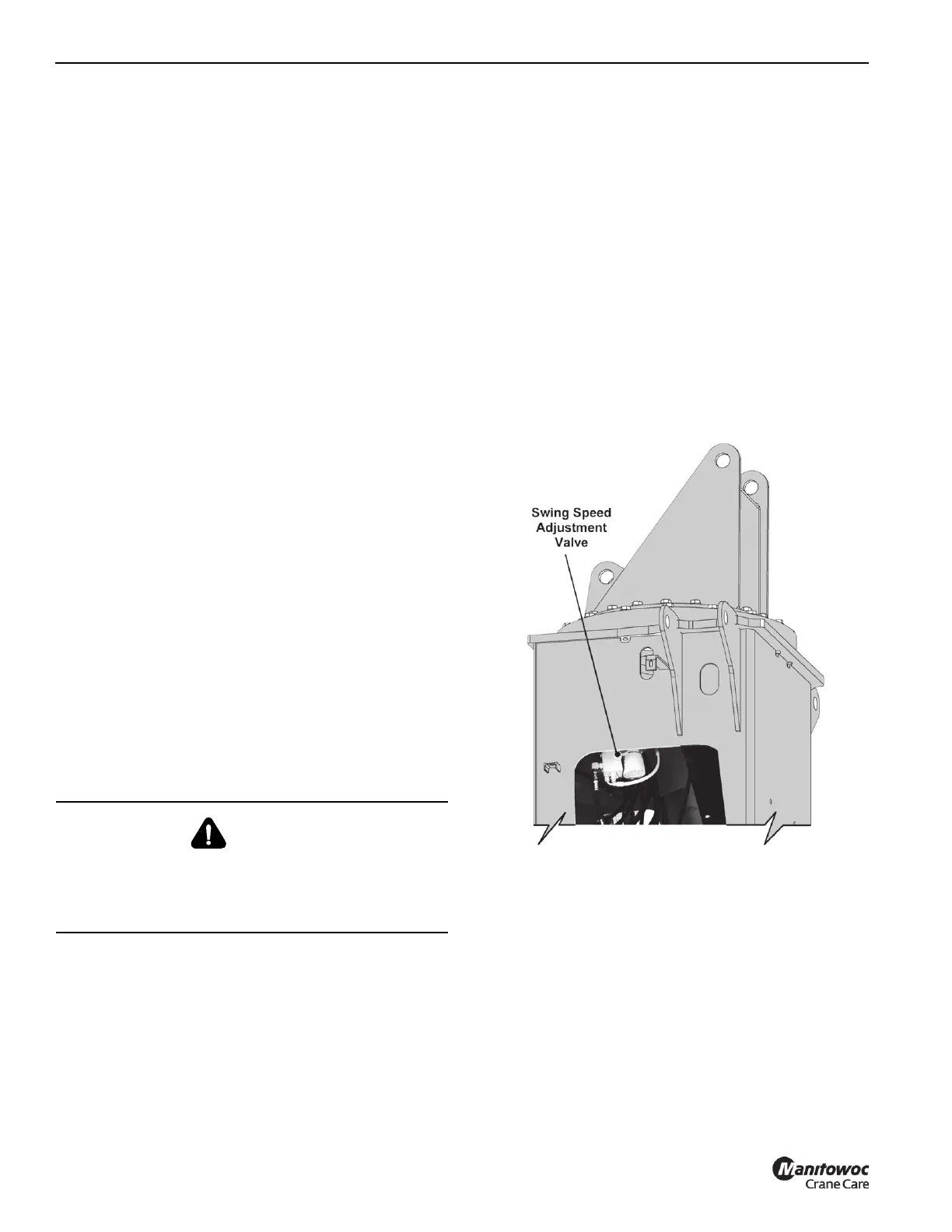

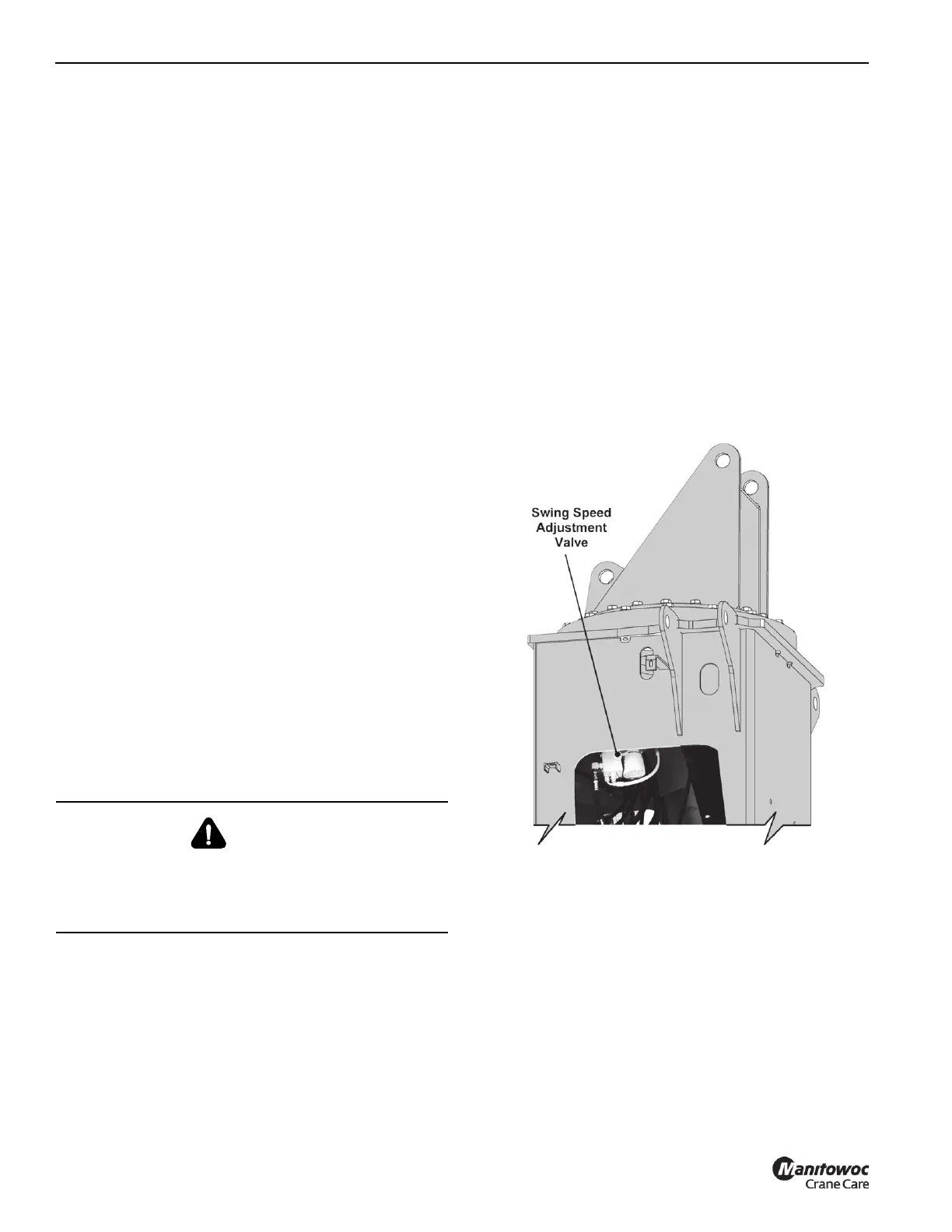

ADJUSTABLE SWING SPEED VALVE

This crane is equipped with an adjustable swing speed

valve. This valve allows the operator to limit the maximum

swing speed of the machine to suit operator preference or

varying applications.

An adjustment dials located on the swing holding valve

mounted on the swing motor inside the crane frame. The

valve has an adjustment screw with a lock collar. Loosen the

lock collar when adjusting the speed, then tighten the lock

collar to maintain swing speed limit setting. The adjustment

dial allows the maximum swing speed to be reduced as

required.

CAUTION

Avoid “shock loads” created by quickly opening and

closing the release while jack is under load. This may

result in overloading of the hydraulic circuit and possible

damage to the jack.

Loading...

Loading...