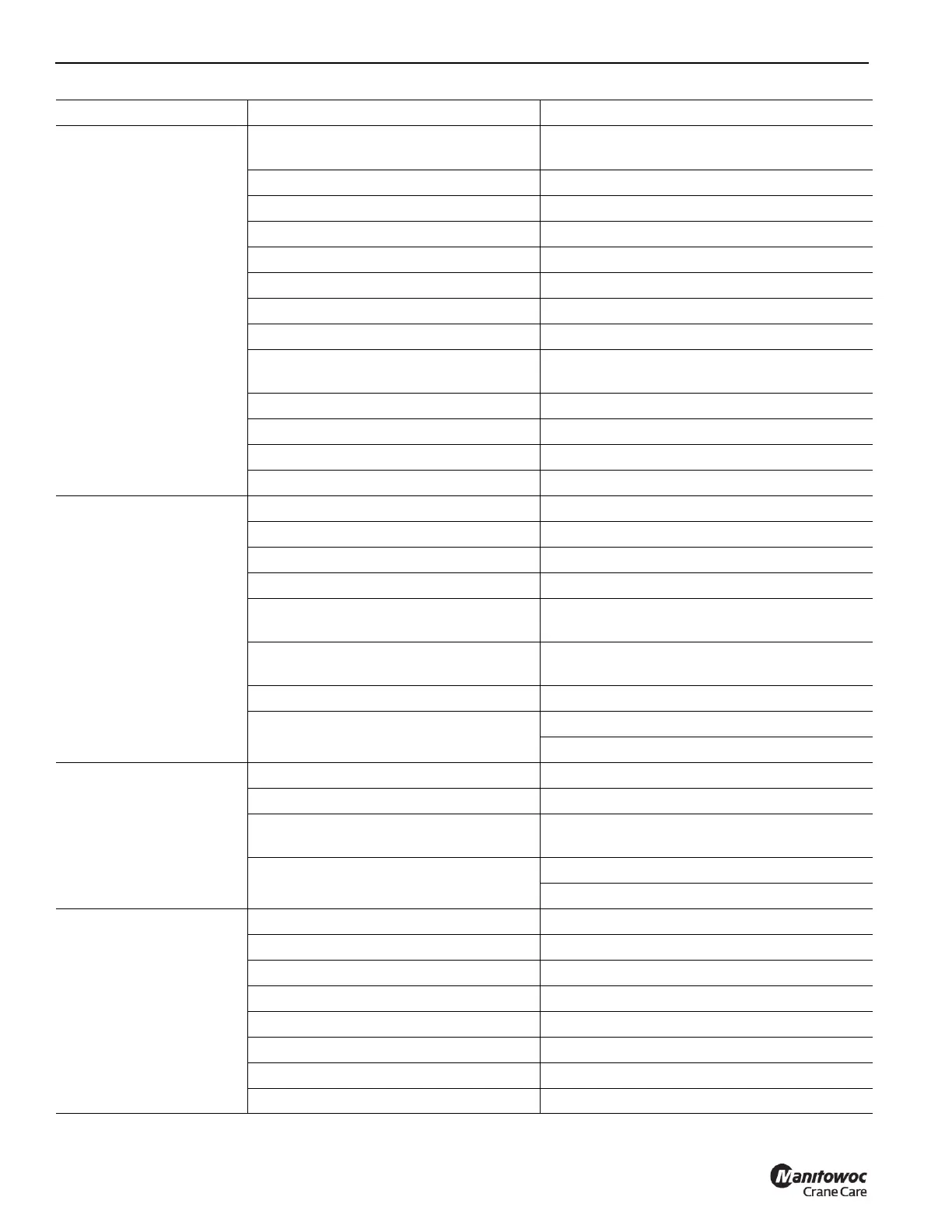

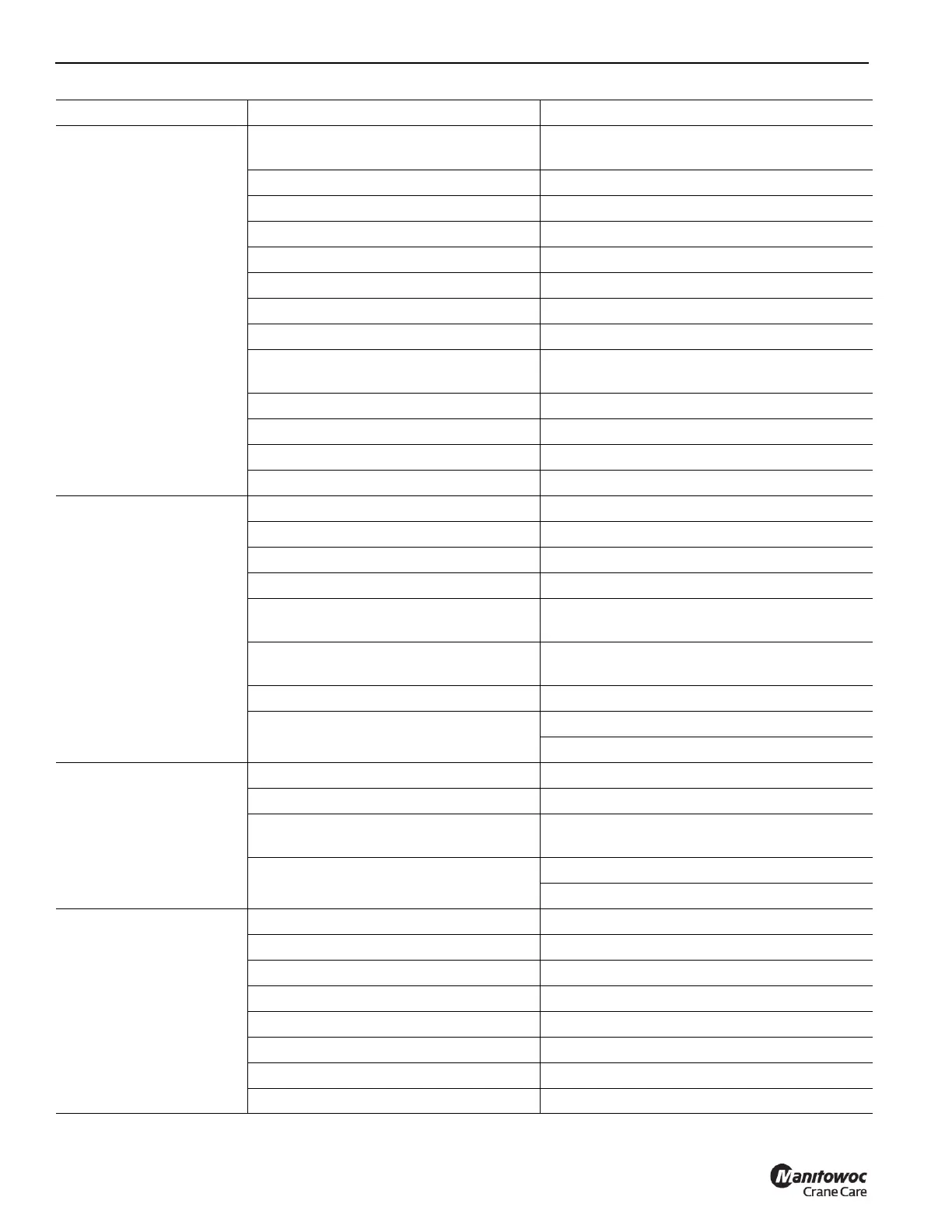

6-6 07-03-19 Control # 091-09

MAINTENANCE CHECKLIST OPERATOR MANUAL 600H SERIES

Poor hydraulic system

performance

Pump not operating at proper speed.

Check PTO ratio, pump size and engine speed

for proper oil flow.

Low hydraulic fluid supply. Check and fill as required.

Relief valve sticking. Remove and clean.

Relief setting too low. Readjust to proper setting.

Worn pump, motor or cylinder. Replace bad part.

Plugged filter. Change filter.

Valve spools not fully open. Adjust linkage so valve has full throw.

Boom holding valves out of adjustment. Adjust or clean as required.

Oil temperature too high.

Run engine at idle with controls in the neutral

position until hydraulic oil light goes out.

Hydraulic oil too cold or dirty. Warm oil or use less viscous oil.

Line restricted. Check lines; clean and repair as required.

Internal control valve crack. Replace valve.

Load too heavy. Check load chart and reduce load.

Swing moves erratic or

sloppily (Standard system).

Loose turntable bearing. Torque bearing mounting bolts.

Loose swing gearbox mounting bolts. Tighten bolts.

Worn gears or bearing. Replace worn parts or adjust gearbox spacing.

Operator control of lever too erratic. Operate controls smoothly.

Motor counterbalance valves dirty or not

set properly.

Clean or replace valves or set at 600 psi.

Brake not holding properly.

Replace worn brake parts or shim brake to proper

torque.

Brake releasing at wrong time or erratically. Bleed brakes with bleed screw on side of brake.

Swing speed adjustment set too low.

Adjust or clean brake for proper release.

Adjust valve on turn motor.

Swing will not turn

(Standard System)

Turn circuit relief valves sticking. Clean and check circuit pressure.

Turntable bearing drag. Lubricate thoroughly as rotating boom.

Brake not releasing properly.

Check for 200 PSI brake pilot pressure. Clean

pilot line or adjust motor counterbalance valves.

Swing speed adjustment set too low.

Adjust or clean brake for proper release.

Adjust valve on turn motor.

Excessive pump noise

during operation.

Excessive pump speed. Adjust foot throttle or check for high PTO ratio.

Low oil temperature. Allow unit to warm up.

Low hydraulic oil supply. Check and fill.

Suction line kinked, collapsed or blocked. Clear blockage.

Hydraulic oil too thick. Warm oil or use oil better suited to environment.

Relief valve chattering. Dirt in relief valve or damaged relief.

Hydraulic tubing vibration. Check for loose tubing.

Tank breather plugged. Clean breather.

Condition Possible Cause Possible Solution

Loading...

Loading...