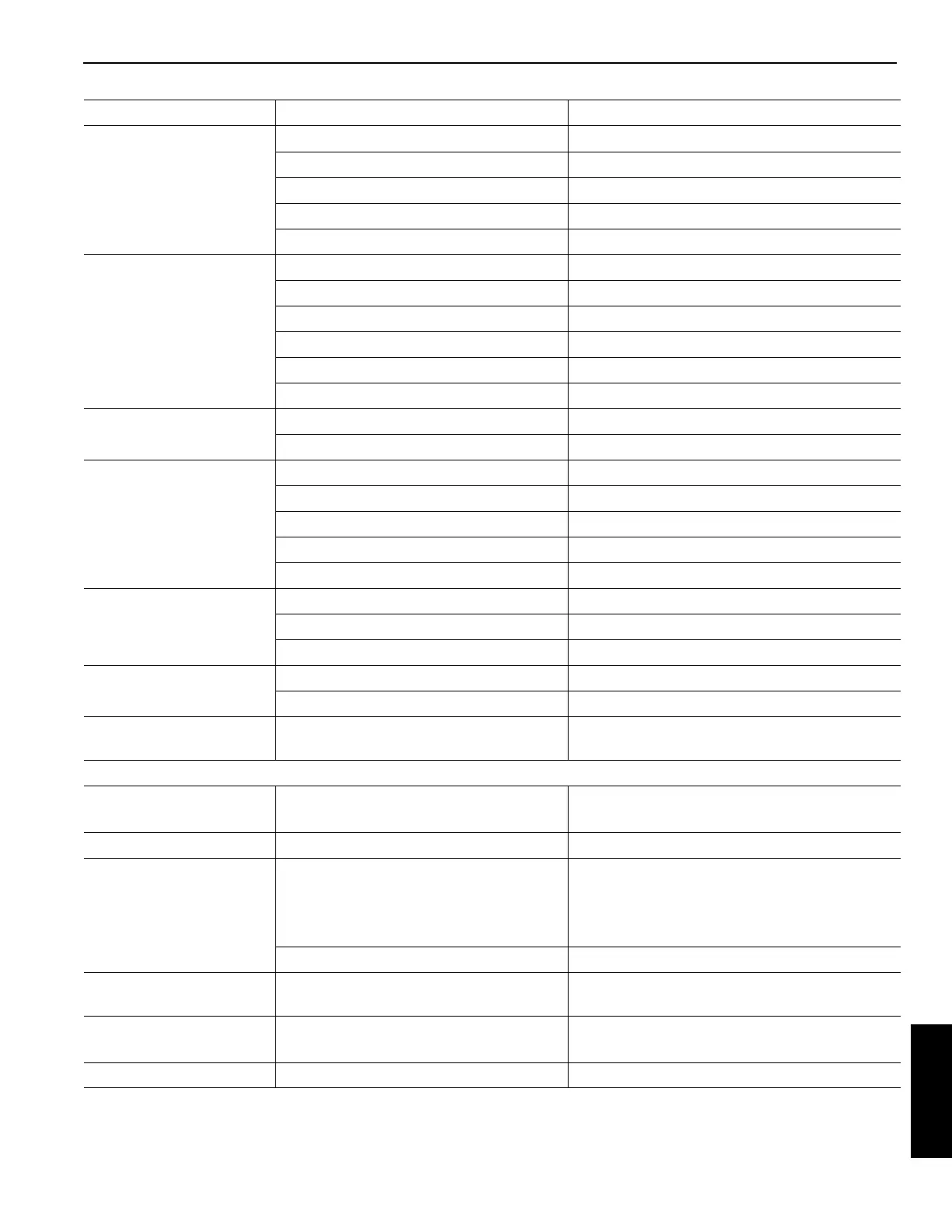

07-03-19 Control # 091-09 6-7

600H SERIES OPERATOR MANUAL MAINTENANCE CHECKLIST

Cylinders drift

Not getting oil to cylinders. Clean and replace as required.

Worn or damaged piston seals. Replace as required.

Air in hydraulic oil. Cycle crane cylinder to remove air.

Loose holding valve. Tighten valve.

Dirt in holding or check valve. Clean valve.

Hoist will not lift or hold

load.

Load too heavy. Change to applicable multipart reeving.

Relief valve setting too low. Check and adjust if required.

Motor worn excessively. Replace motor.

Counterbalance valve defective or leaking. Clean and replace as necessary.

Anti-two-block system defective. Repair anti-two-block system.

Brake worn out. Repair or replace brake.

Hoist gearbox heats.

Gearbox grease low. Check and fill as required.

Duty cycle too high. Reduce cycle time or speed of Hoist.

Boom chatters during

extension/retraction or

doesn't proportion properly.

Boom sections need lubrication. Grease boom.

Wear pads not shimmed correctly. Re-shim as described in boom assembly section.

Worn wear pads. Replace pads.

Extension cables out of adjustment. Readjust cables and tension properly.

Extend or retract cables broken. Disassemble, inspect, and replace cables.

Boom will not extend.

Proportioning cables not attached. Reconnect, replace and/or adjust cables.

Anti-two-block system shut down. Lower hook, and extend load.

Defective anti-two-block system Repair ATB if defective.

System is in a state of

constant cut-out.

Blown fuse at the crane console. Replace fuse.

ATB switch open. Ensure that ATB switch is closed.

System cuts out too early or

too late.

RCL programmed wrong. Reprogram RCL with correct lift values.

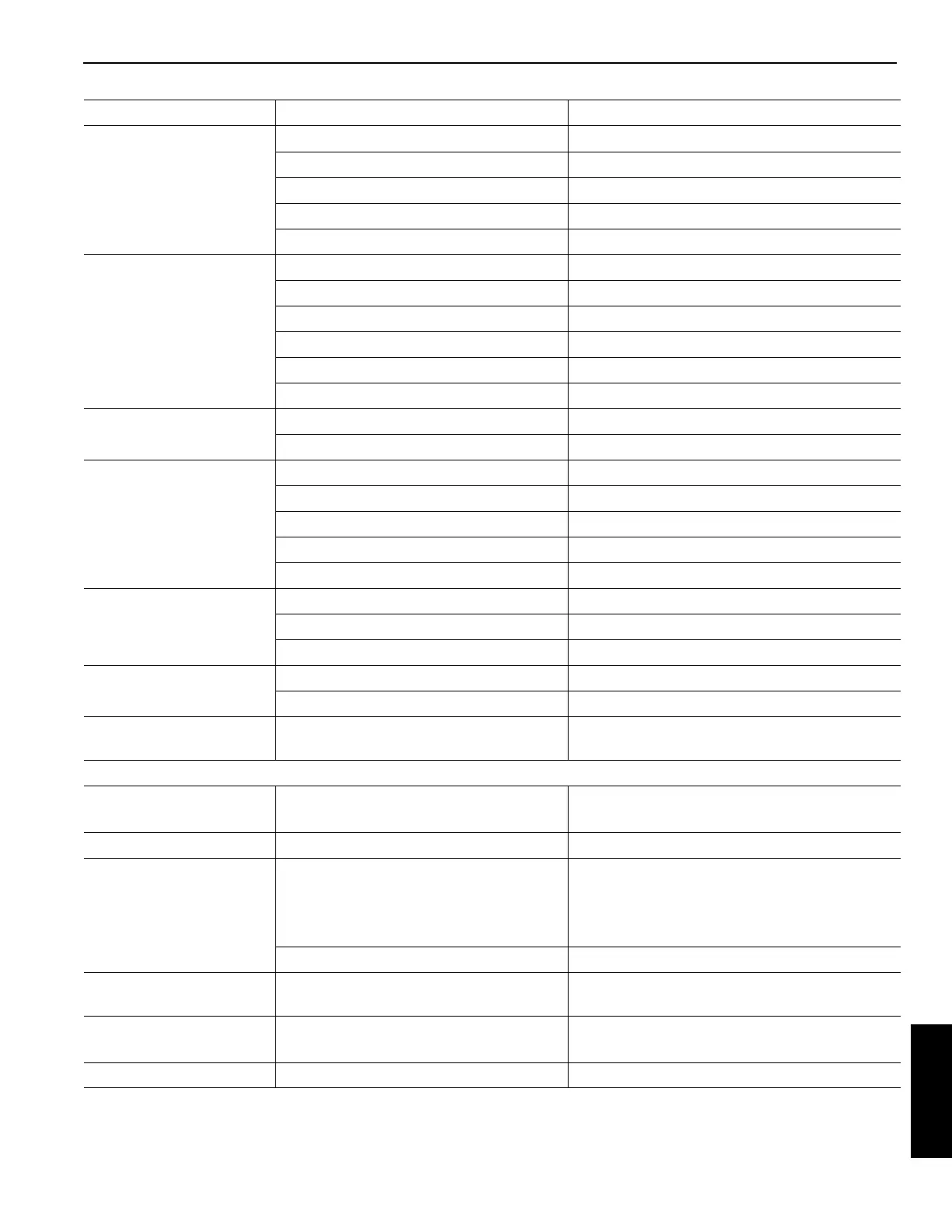

Jib Jack Troubleshooting

Will not lift load.

No oil in system.

Release valve not closed.

Add oil to reservoir.

Turn handle clockwise tightly.

Will lift load only part way. Oil level low. Add oil to reservoir tank.

Will lift load but will not

hold.

The following valve or valves leaking.

a. Suction valve

b. Delivery valve

c. Release valve

Replace jack

Packings worn or damaged. Replace jack

Jack will not lower.

Release valve stuck, probably dirt or

foreign matter.

Transfer load then replace dirty oil, flush oil

reservoir with non-flammable solvent.

Poor lifting.

Dirty oil.

Air in hydraulic system.

Change oil.

Purge air from system.

Poor pumping action. Oil seal for pump unit worn or damaged. Replace jack.

Condition Possible Cause Possible Solution

Loading...

Loading...