43

S-801 Series

SOT-23-5

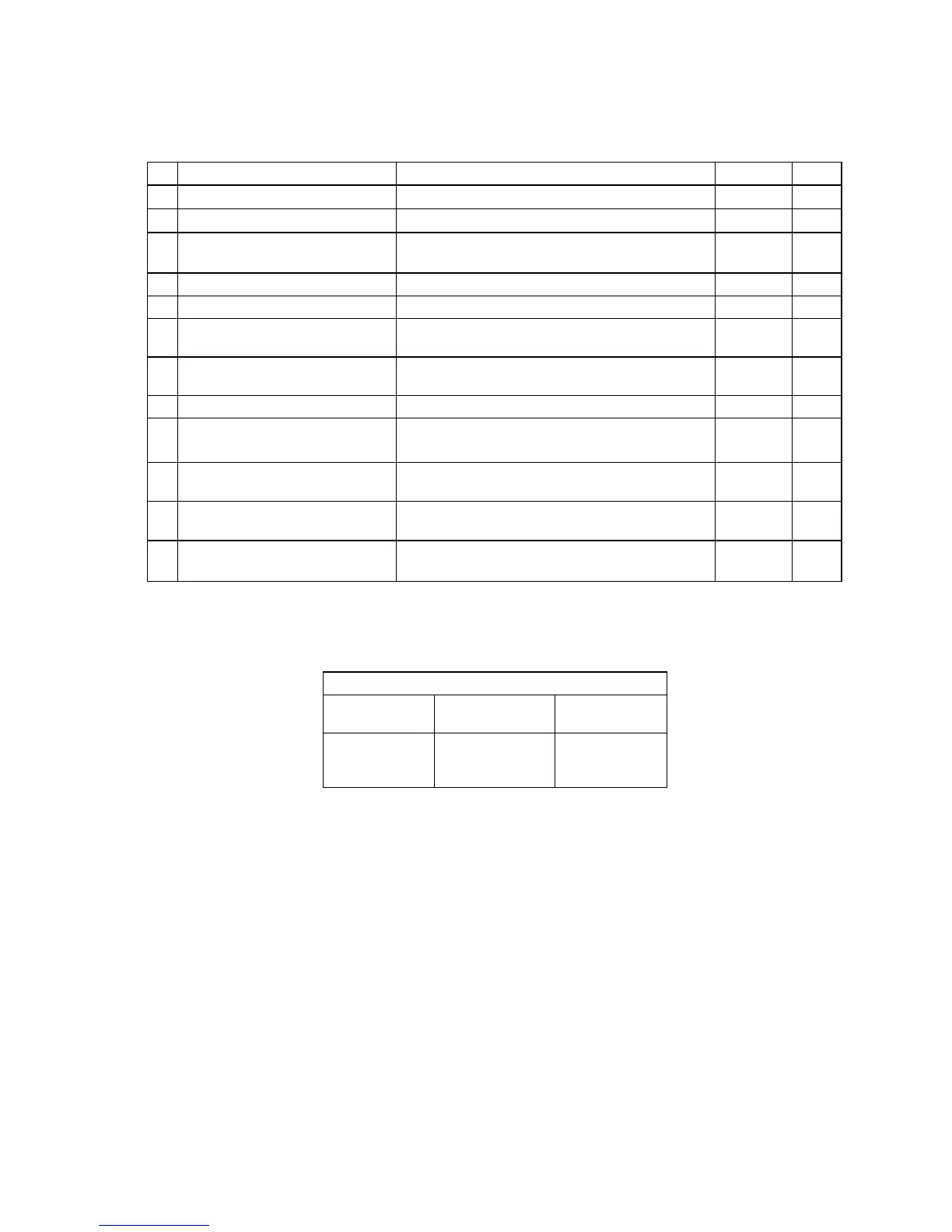

No. Test item Test Condition Test Time r/n

1 # High Temperature Bias

Ta=125 °C V

DD

=Vabs max.×0.9

1000 h 0/22

2 # Temperature Humidity Bias

Ta=85 °C RH=85 % V

DD

=Vabs max.×0.9

1000 h 0/22

3 # Un-saturated

Pressure Cooker Bias

Ta=125 ˚C RH=85 % P=2×10

5

Pa

V

DD

=Vabs max.×0.9

100 h 0/22

4 # High Temperature Storage Tstg max.=150 °C 1000 h 0/22

5 # Low Temperature Storage Tstg min.=−65 °C 1000 h 0/22

6 # Temperature Cycle

( Gas phase )

Tstg max.=150 °C , Tstg min.=−65 °C ( 30min each ) 200 cycles 0/22

7 # Thermal Shock

( Liquid phase )

Tstg max=150 °C , Tstg min.=−65 °C ( 5min each ) 100 cycles 0/22

8 Solderability T=230 °C ±5 °C 5 s 0/11

9 Lead Strength

(Pull test)

Pull force ; 2.5 N 30 s 0/11

10 Lead Strength

(Bending test)

Load ; 1.25 N

45 degree Bend a lead

Twice 0/11

11 ESD V=±2000 V C=100 pF R =1.5 kΩ

Ref. To V

DD

/ V

SS

( 5 units for each direction )

5 pulses 0/20

12 Latch Up

±100 mA ( V

CLAMP

= Vabs max. ) 10 ms pulse

V

DD

= Vopr max.

1 pulse 0/5

Remark : Vabs max. = Absolute maximum voltage , Vopr max. =Maximum operation voltage

# : Each test designated # is performed after Pre-Treatment finished.

Pre-Treatment consists of High Temperature Storage ,Temperature Humidity

Storage and Soldering Heat. (See the table below.)

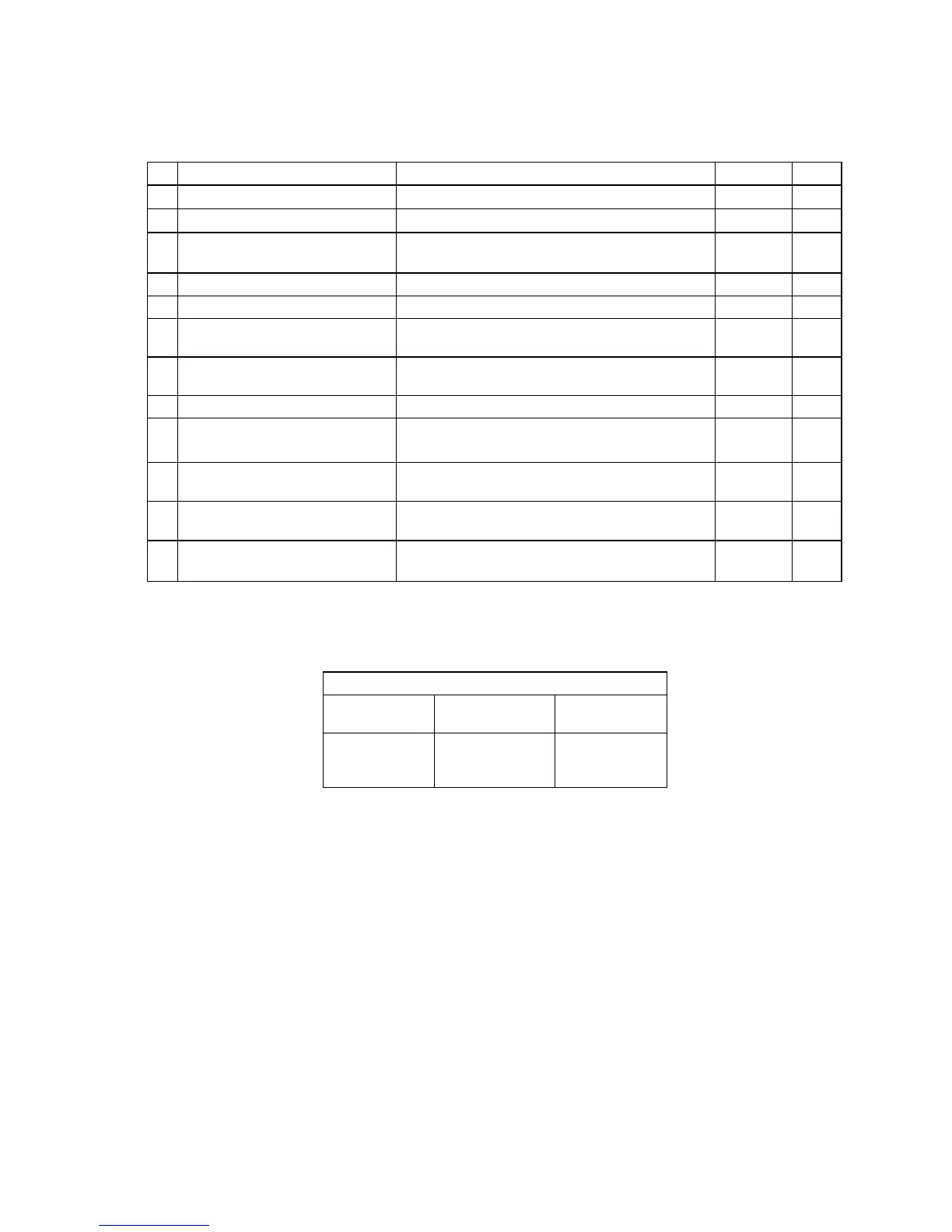

Pre Treatment

High Temp.

Storage

Temperature

Humidity Storage

Soldering Heat

Ta=125 ˚C

t=24 h

Ta=85 ˚C

RH=65 %

t=168 h

Solder Dipping

T=260 °C

t=10 s

7. IC DATA

IC29 : S-80145

Loading...

Loading...