16

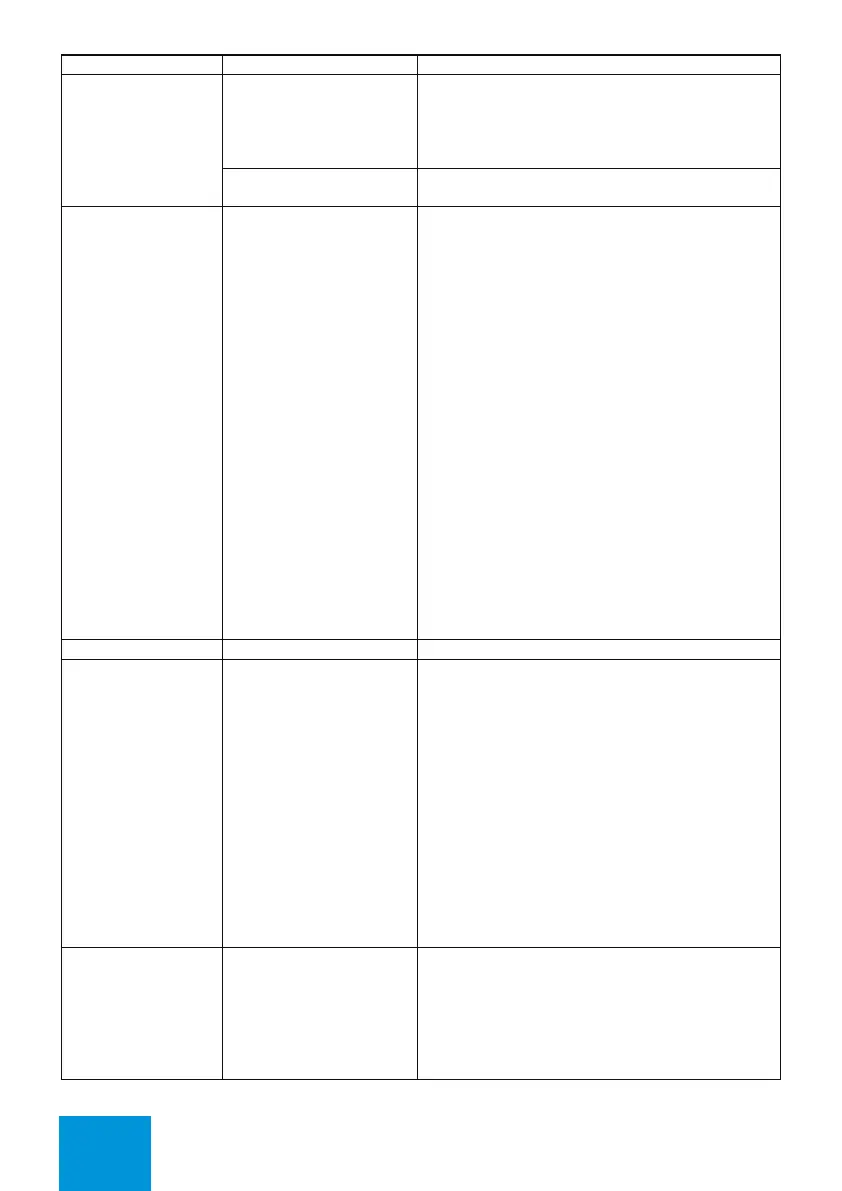

No power: Power

indicator lamp is not lit

Unit requires 120V power. Use unit when

power is restored.

Check circuit breaker and reset if needed.

Check ground fault circuit interrupter (GFCI)

if circuit includes one and reset if necessary.

Check power plug and ensure properly plugged.

Plug the power plug properly.

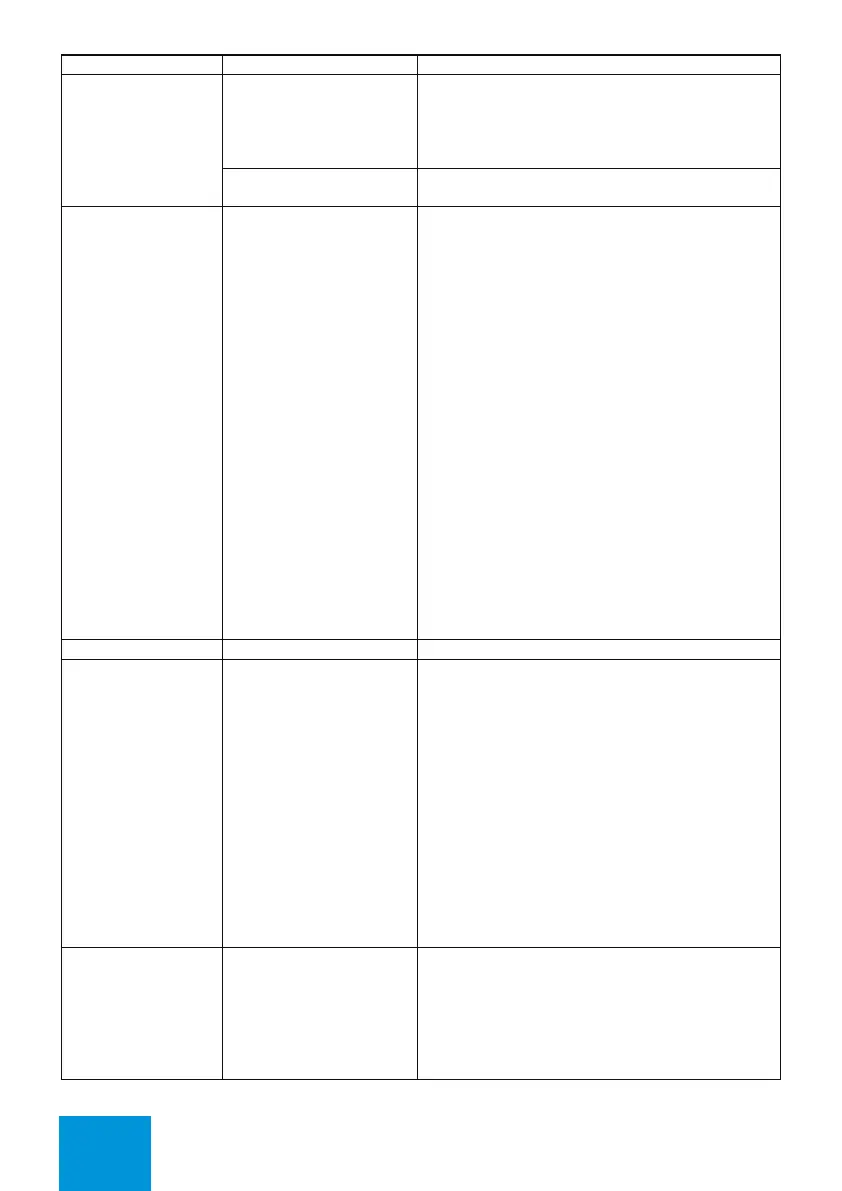

There is no hot water

ow when a hot water

faucet is opened.

Water valve closed

Power outage

Flow is too low or became

too low. (less than 0.66

gallons per minute (gpm) or

2.5 liters per minute (l/m)

Freezing temperatures may

have frozen water in the

heater or hot water system.

Fuel gas meter special

control restricons

Distance from heater to

source is long

Fuel gas valve needs to be open

Rell source tank (if applicable)

Open the water inlet valve.

Unit requires 120V power to operate.

Flow is below the lower limit necessary for

stable burner operaon and proper

temperature control. Increase the hot water

ow to enable system.

See “No Flow Due to Expected Frozen

Heater” secon of this manual for procedure

to thaw unit.

Some fuel gas valves may have special

restricons or digit

al controls that use.

Consult your gas supplier and/or a service

professional for assistance.

Allow me for hot water to travel through

system to reach the point of use.

Hot water is not the

right temperature

(too hot or too cold)

Temperature set point was

reset due to power outage.

Flow is beyond capacity

Incoming water is too warm

Power outage restores default sengs and

custom set points must be re-entered to unit

Desired water ow is above maximum

capacity of unit. Reduce user ows to re-

establish control of temperature

If incoming water to unit is very warm and

the ow is just above minimum

requirements, the heat generated by the

burner while operang at minimum capacity

can make the water hoer than desired.

Increase the hot water user ow so that the

burner system can control the temperature.

Hot water ow

produced is lower than

expected

Water source is restricted

Heat exchanger in unit is

scaled

Incoming water temperature

Check and fully open water inlet valve(s)

Check and clean inlet water screen

Clean heat exchanger by ushing per

maintenance procedure.

Colder than normal incoming supply water

Loading...

Loading...