CRASH control programming 13

3.

CRASH CONTROL PROGRAMMING

The CRASH control must be intended as an ALARM signal that is given when the

grinding wheel collides against the workpiece or other devices and/or parts of the

grinder due to a malfunctioning or to a bad programming.

3.1

Programming procedure

Press the key , if present, to select the CRASH channel.

1.

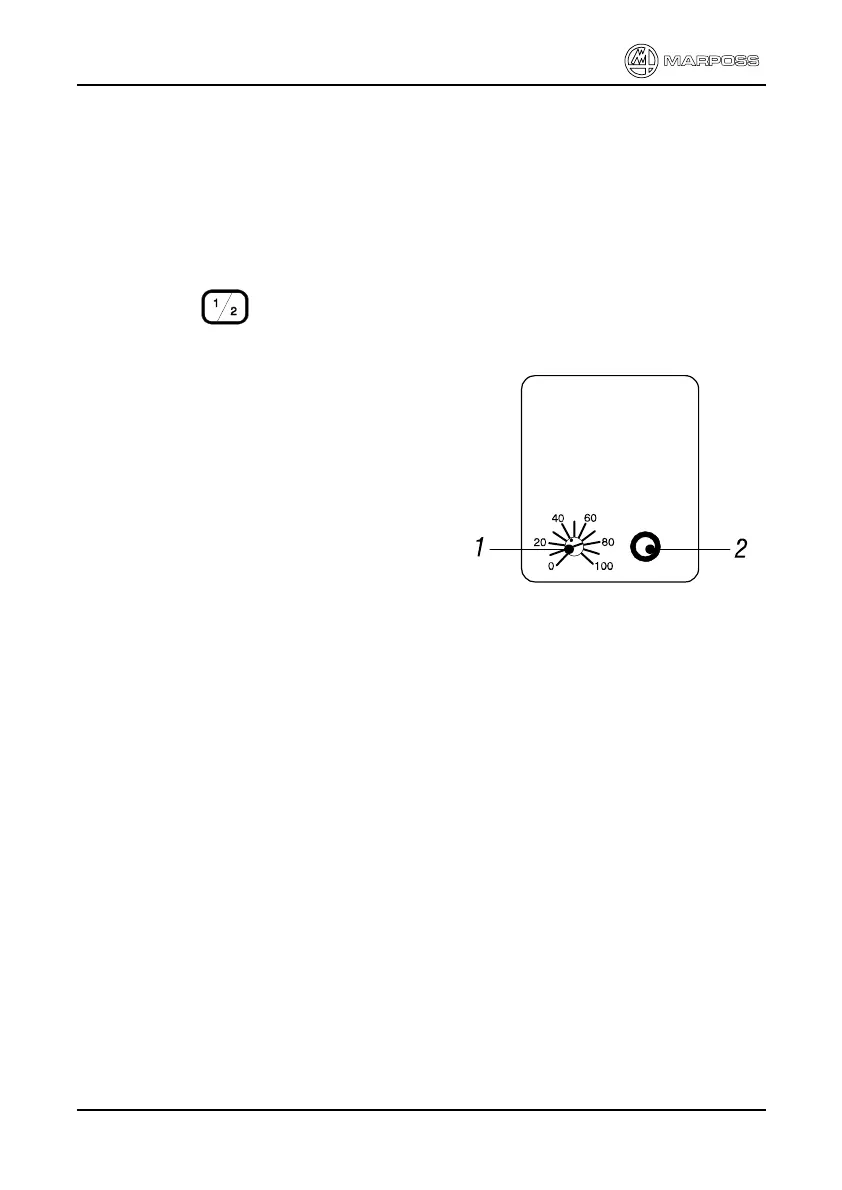

Set the sensitivity on the potentiometer

1 approximately to the center of its

range (40-60) or to the same value

relative to the GAP control (in case of

dual channel units)

2.

Simulate a few cycles and all the possible machine conditions (grinding,

loading, unloading, dressing, etc) to identify the maximum noise condition

and adjust the sensitivity to have the displayed value just below 6.5 on the

graduated bargraph display of the E20N (triggering point of the command).

In case the above procedure leads to the definition of a CRASH limit value

which a much lower sensitivity than in the GAP programming, to have a

reliable crash control it may be necessary:

• to program the sensitivity on potentiometer 1 only 10-20% lower than for

gap control.

• disable the crash control in the normal machine conditions that exceed

the crash value.

Loading...

Loading...