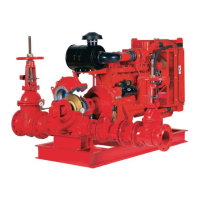

11. POSSIBLE FAILURES, CAUSES, SOLUTIONS

Possible failures and solution strategies are listed in the table below. Please apply to the Customers’ Service Department of our company when a

generic solution is not found to your problem.

While the failures are repaired the pump must always be dry and un-pressurized.

The pump delivers insufficient capacity

Discharge head too high

Very high counter pressure

Pump and/or pipe cannot discharge air,

cannot suck

Occurrence of air pockets inside the pipe

NPSH is too low

Readjust the operating point

See if there is any undesired material

inside the pipe

Vent completely the pump and the pipe

Change the piping configuration

Increase the liquid level

System pressure is lower than the

requested pressure level

Speed too high

Liquid pumped of different specific gravity

and viscosity than that for which pump is

rated

Engine works at two phases

Adjust the operating pressure to the

label value

Decrease the speed

Increase the engine power

Replace the fuse and control the

electrical connections

System pressure is higher than the

requested pressure level

Set the operating pressure to the label

value

Bearing temperatures are high

Worn out coupling

Too much, too little or improper

lubrication

Increase in axial forcing

Replace the coupling

Change the oil, decrease or increase its

quantity

Clean the balance holes on the impeller

disc

Excessive leakage from the stuffing box

Worn out gland

Loose gland

Use brand new gland

Change the stuffing bush

Tighten the gland nuts

Worn out motor or pump ball bearings

Cavitation

Worn out or misaligned coupling

Operation in the far left or right of the

performance curve

Replace

Close the delivery partially in order to

reduce the capacity.

Replace the coupling or align it

Operate the pump at its label setting

Excessive increase in pump temperature

Pump and/or pipe can neither discharge,

nor aspirate air

Too low capacity

Bleed completely the pump and the

pipe

Open more the valve

Pump and/or pipe can neither discharge,

nor aspirate air

NPSH is too low

Internal components of the pump are

worn out

System pressure is lower than the

requested pressure level

Coupling is misaligned

Too much, too little or improper

lubrication

Rotor unbalanced

Improper bearings

Bleed completely the pump and the

pipe

Increase the liquid level

Replace the worn out components

Adjust the operating pressure to the

label value

Align the coupling

In case of continuous overload,

decrease the impeller diameter

Change the oil, decrease or increase its

quantity

Balance the impeller again

Use new bearings

Loading...

Loading...