After all these processes are accomplished, remove the rubber gasket

from the suction and discharge openings. Open their holes and mount

them again on their intended place.

6.5.3. Specification of work after installation of piping and piping

system

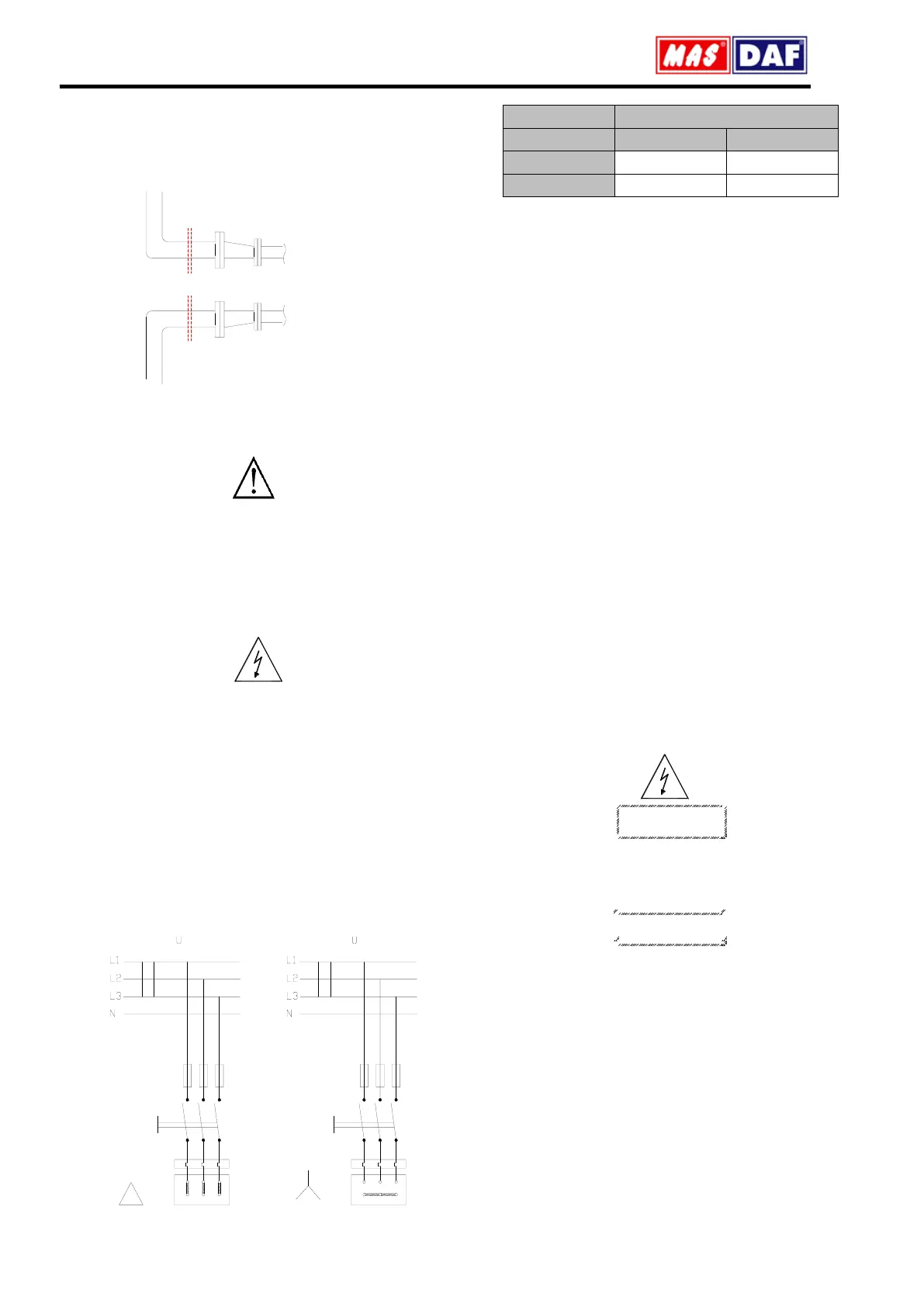

Pump entry

Installing Pipes

lower side entry line

Pump entry

flange

flange

Upper side entry line

Figure 8. Piping system

An illustrative piping system is shown in Figure 10. Appropriate

manometers shall be mounted on suction and discharge pipe lines.

Complete the auxiliary pipe connections in piping system if exist (cooling

to bearing housing, and stuffing box (seal), relief pipe, oil pipe etc.)

6.6. Motor Connection

Motor shall be connected by an electrical technician according to the

connection (switch) diagram. Local electricity policies and current VDE

regulations have to be applied.

Electrical connections have to be made by authorized electricians.

In dismantling the pump, make sure the electricity is cut off before

taking the motor cover out.

Use the appropriate electrical connection to the motor

In environments where there is a risk of explosion, prescribed protective

law and regulations shall be applied by competent authorities.

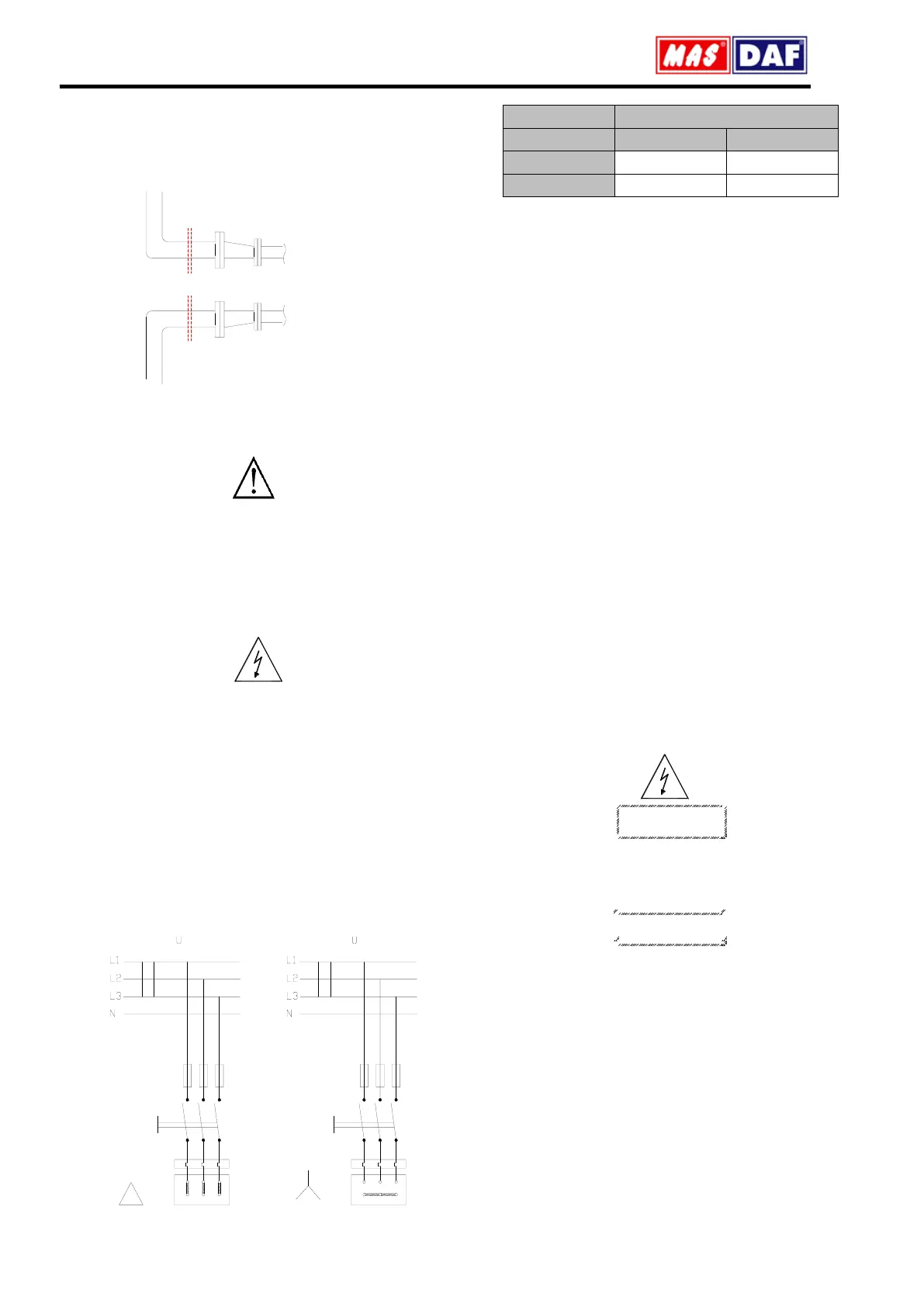

6.6.1. Motor Connection Diagram

Motors requiring high moments at start up shall not be connected star-

delta

Frequency controlled motors, require high moment at start up and have

to be cooled properly at low speeds. Provide the necessary cooling for

the motors.

W1V1U1

W2 U2 V2

delta

star

U1 V1 W1

W2 U2 V2

Figure 9. Electric Connection Diagram

6.6.2. Motor Protection

Three phased-motor shall be connected to power supply.

Wait the motor to cool down when thermic protected motor breaks in

circuit due to the overheating. Make sure the motor does not start

automatically until it cools completely

In order to protect the motor from overcharging and short circuit use a

thermic or thermic-magnetic relay. Adjust this relay to the nominal

current of the motor.

Electrical equipments, terminals and the components of the control

systems may carry electric current even though they are not

operating. They may cause deadly and serious injuries or

irreparable material damages.

7. COMMISSIONING, START UP AND OPERATING

7.1. Preparations Before Start-Up

Oil Check: Ball bearings are used in YPSP type fire pumps. Long-life, NU

series cylindrical bearings and one row, 63..-C3 series ball bearings are

used respectively on the motor and the shaft sides, balance the axial

force acting on the impeller. Bearings are lubricated with grease.

Check pump seals

Make sure that the pump and the suction pipe is completely filled with

water before the starting. If the pump operates on a positive suction

head, no problem will be encountered. Suction valve is opened and air

drains are un-tightened.

Pumps with foot valve are filled with water by opening the pump filling

tap or, one takes advantage of the water accumulated in the discharge

pipe and by using a small valve the check valve is bypassed and the

pump is filled.

In vacuum pump driven pumps, by operating the vacuum pump one

achieves to fill the pump via increasing the water level in the suction

pipe

Do not start your pump dry

7.2. Checking the Direction of Rotation

The direction of rotation is indicated on the pump label with an arrow.

Apart from special cases, it is clockwise direction when looking from the

motor end. Observe if the pump is rotating in the expected sense by

starting the motor for a very short instant. If it is turning in the opposite

sense, interchange any of two motor leads.

If the motor connection is delta, open the discharge valve slowly.

If the motor connection is star-delta, set the time relay to maximum 30

seconds. Monitor the passage from star to delta by pressing the start

button. As soon as you are assured that the connection is delta, open

the discharge valve slowly. Continue opening the valve until you read

the amperage on the electrical panel

One should always check the labels which show the direction of rotation

and the direction of fluid flow. If you dismount the coupling protection to

monitor the direction of rotation, do not restart the engine before

remounting the protection.

Loading...

Loading...