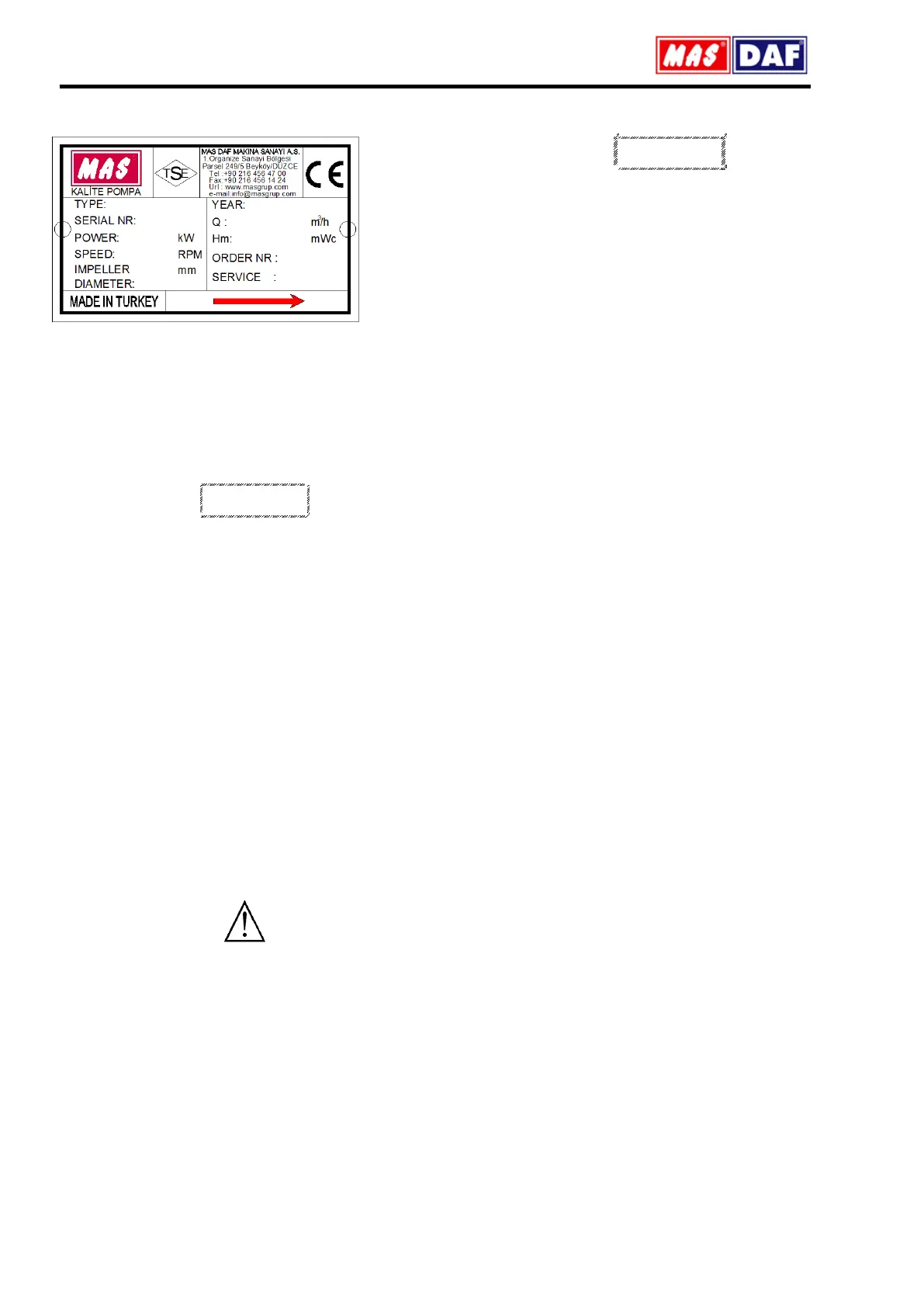

Pump Label

2.2. Performance Information

Actual performance of the pump can be obtained from the order page

and/or from the test report. This information is given on the pump label.

The performance curves given in the catalog are valid for water whose

density and viscosity are ρ=1 kg/dm

3

and ν=1 cst. respectively. For

those liquids whose densities and viscosities are different from those of

water, please consult with MAS DAF MAKİNA SANAYİ A.Ş. since the

performance curves vary with density and viscosity

Do not operate the pump with a motor that has a different power

except for the given catalog and label values.

The pump is not to be operated at off-design point given in the order and

supplied from the firm.

It is necessary to ensure that the instructions are obeyed for the safe

running of the pump.

2.3. Warranty Conditions

The entire products in our selling program are warranted by MAS DAF

MAKINA SANAYİ A.Ş.

Warranty period is 12 months after delivery.

Life of the product is 10 Years.

The warranty conditions will only be valid when all the instructions about

installation and start-up operations of the pump unit are taken into

account.

2.4. Test

All Pumps are dispatched for sale when all the performance and pressure

tests are completed. Proper assurance of material and fault-free

operation of pumps whose performance tests are made is under the

warranty of MAS DAF MAKİNA SANAYİ A.Ş.

2.5. Pressure Limit

Pressure at the discharge flange must not exceed 150% of the pump’s

head.

3. SAFE OPERATİNG CONDİTİONS

This manual contains main safety instructions for the installation,

operation and maintenance. It must be read by the personnel who are

responsible for installation and operation. This manual should always be

kept near the installation location. It is important to comply with safety

precautions stated in page 1 along with the general safety instructions as

well as preventive measures repeated in other sections of this manual.

3.1. Training of personnel

Installation, operation and maintenance personnel must have necessary

knowledge in order to accomplish the given job. The responsibility,

adequacies and controlling duties of such personnel must be determined

by the costumer. It has to be certain that these personnel comprehend

totally the content of the operating manual.

If the personnel do not have enough knowledge, required training must

be given by the costumer. If training support is needed by the costumer,

it will be provided by the manufacturer/seller

Untrained personnel and unwillingness to comply with safety instructions

may be risky for both machine and environment. MAS DAF MAKİNA

SANAYİ A.Ş. is not responsible for this kind of damages.

3.2. Hazardous conditions that may occur when one does not

comply with the safety instructions

Incompliance with safety regulations may put the personnel, the

environment and the machine in danger and thus may cause damages.

Incompliance with safety regulations may give rise to situations listed

below

Important operational functions of the factory may stop

Maintenance may get difficult.

One may get injured by electrical, mechanical or chemical hazards.

3.3. Safety measures for operator

Dangerous, hot or cold components in the pump area must be covered so

that one cannot touch them.

Moving components of the pump (such as coupling) must be covered so

that one cannot touch them. Those covers must not be dismounted while

the pump is running. Dangers that results from electrical connections

must be removed. To get more information about this subject, you can

refer to VDE and domestic electrical instructions.

3.4. Safety measures for maintenance and installation

The costumer must assure that all maintenance, check and installment

tasks are performed by qualified personnel. Repair work must only be

performed while the machine is not running.

The pump and its auxiliary system must be cleaned thoroughly if it

contains hazardous liquids. At the end of the repair work, all safety and

protective equipment must be re-installed.

3.5. Spare parts replacement

Replacement of spare parts and all modifications must be done after

contacting with the manufacturer. Spare parts and accessories certified

by the manufacturer are important for the safe operation of the system.

Notice: MAS DAF MAKİNA SANAYİ A.Ş. is not responsible from the

usage of improper spare parts.

4. TECHNICAL INFORMATION

4.1. Design

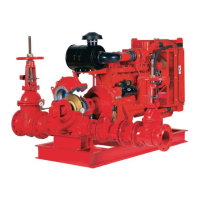

These are double suction, split case, horizontal pumps. Since the upper

cover of the pump is dismountable, all the internal components can easily

be replaced without dismounting the pump case and the fittings.

Stuffing box is cooled with water. Gland is easily dismountable type. In

this way, it is very easy to replace and fit up additional seals. Since the

impeller is double suction type, axial force is balanced automatically. .

4.1.1. Locations Of Flange – Flanges

Pumps have normally clockwise rotation when viewed from the driver

side. In this case, suction opening is on the right and discharge opening

is on the left. Suction and discharge flanges are concentric. Suction and

discharge flanges are in accordance with DIN 2533-PN 16. It is possible

to manufacture pumps with counter clockwise rotation.

4.1.2. Auxiliary fittings

Please refer to the technical drawing of the pump for necessary auxiliary

fittings

4.1.3. Impeller

Specially and carefully designed impellers are closed type and have

Francis type blades. They are balanced both statically and dynamically

Loading...

Loading...