4.1.4. Shaft

The shaft is longer for standard YPSP type pumps which have soft

packing applications.

4.1.5. Bearing and Lubrication

Rolling bearings are used in YPSP type pumps. They support radial load

caused by the impeller. A NU series cylindrical bearing at the motor side

of the pump and a 63-C3 series ball bearing on the other side of the shaft

are used. They are all long life rolling bearings. Rolling bearings are

lubricated with grease.

Since the impeller is double suction type, the axial force balances

automatically. To prevent the leakage flow into bearing housing, there are

deflectors in front of the bearing covers.

4.1.6. Seals

In YPSP type pumps gland squeezed, teflon knit soft packing are used.

There is a lantern ring in the stuffing box.

Non-cooled packing is standard. (It is acceptable up to 90

o

C )

(See The Fig. 11 : Design with soft packing)

4.2. Construction Of Pump Group

4.2.1. Drive

A hermetic, 3 phase, fan cooled, squirrel caged,in according to DIN

42673-IM 1001B3 type electrical motor which complies with DIN IEC and

VDE is used to drive the pump in proper speed and power.

Specifications of electrical motor

Isolation class : F

Protection class : IP 54-IP 55

Frequency : 50 Hz.

Running type : S1

Start up type : 3x380 V(Y) up to 4 kW

More than 4 kW, 3x380(Δ) + (Y/ Δ)

There is another possible application to drive the pump with a diesel

engine.

4.2.2. Coupling and coupling cover

A flexible shaft coupling with or without secondary component in

accordance with DIN 740 is used. A coupling cover is given in

accordance with EN 294 in case of the pump group includes the coupling

and chassis.

Pump can only be run with a coupling guard in

accordance with EN 294according to safety instructions.

If there is no coupling cover, it is provided by the operator.

4.2.3. Base plate

It is manufactured from U profile steel in accordance with DIN 24259

5. TRANSPORT AND STORAGE

Suction, discharge and all auxiliary fittings must be closed during

transport and storage. Dead-end covers must be removed while the pump

unit is being installed.

5.1. Transport

Pump and pump group must be carried safely to the installation location

by lifting equipments.

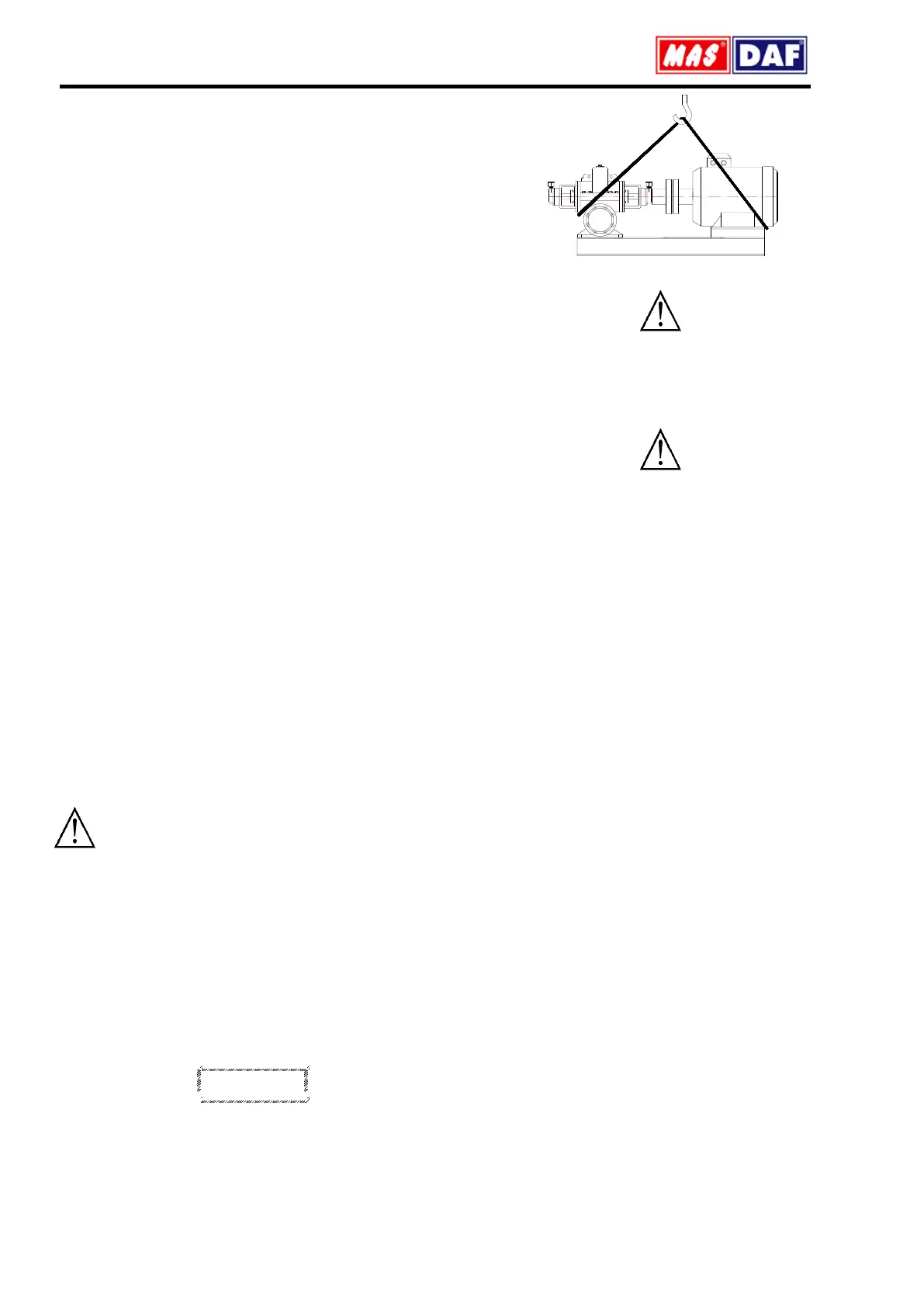

Current general lifting safety instructions must be applied. Please use a

suspension system shown in figure while you are carrying and lifting the

pump unit. The suspension rings may be broken because of the

excessive load and may result in a damage of the pump. Prefer fabric

cable for suspension

Fig.1: Transport of pump group

Incorrect lifting may damage the pump unit and cause injuries

Damages caused in transport.

Check the pump when it is delivered to you. Please let us know of there is

any damage.

5.2. Storage

Please keep the unit clean and dry area during storage.

If the pump is out of use for a long time, please consider the instructions

below:

1. If there is water inside the pump, drain it.

2. Clean the pump casing and impeller by jetting clean water for a short

time.

3. Empty water inside the pump casing, suction line and discharge line.

4. Add small amount of antifreeze inside the pump casing if it is not

possible to empty it completely. Rotate the pump shaft by hand to mix

the antifreeze.

5. Close the suction and discharge exits with gasket

6. Spray an anti-corrosive into the pump casing.

7. Rotate the pump shaft by hand once in every month, in order to protect

it from freezing and to lubricate the bearings

6. ASSEMBLY / INSTALLATİON

6.1. Installation

In our standard production, the pump and the motor have been installed

in a common base plate.

6.1.1. Location of Installation

Pump shall be installed in a location where the control and the

maintenance of the pump are easily made. The pump room shall be

suitable for operation of lifting systems such as freight elevator, forklift,

etc.

The pump group should be installed in the lowest possible location of the

pumping system in order to achieve the highest suction pressure.

6.1.2. Location of Installation- Local Ambient Temperature

When the local ambient room temperature exceeds +40

0

C in a pumping

system, suitable ventilation should be provided in order to remove the

heat dissipated to the environment and supply fresh air.

6.2. Type of Connection

Type of connection depends on the design type and the size of the pump

and the motor, as well as the local installation conditions. Foot-mounted

horizontal pump-motor units have been installed in a common base plate.

6.3. Foundation

6.3.1. General

Base plate of the pump must be grouted. The foundation shall be of

concrete or steel framework.

NOTE: The foundation shall distribute the weight of the pumping group

evenly.

Loading...

Loading...