21

Charging the Master Controller 2.0 Refrigeration System

Note: If you are a first time installer of a Master Controller 2.0 system,

please call Master-Bilt for on-phone training.

Since the system is designed with free floating head control, the head pressure control valve is not installed in

this type of system. Therefore, the compressor operates at its highest EER value.

During initial pull down, after primary charge while the system is running, a large evaporator superheat is

built up. The electric expansion valve is then open all the way. If the system is charged full sight glass during

this period, the system is already overcharged.

Note: The liquid line size is determined by conventional piping practices

for air and electric defrost. For reverse cycle defrost, the liquid line must

be selected by choosing the liquid line one nominal step larger than the

conventional approach. For example: for an evaporating temperature =

-20ºF, refrigerant R-404A, and a capacity of 20,000 Btuh, the conventional

tables will suggest a liquid line size of ½” OD. When utilizing the reverse

cycle feature of the Master Controller, the liquid line size should be 5/8”

OD. When utilizing the electric or air defrost scheme, there is no need to

make the line larger.

All suction lines may be chosen by conventional practices. Please note

the “stubs” at both the evaporator and condensing unit do no

necessarily mean that this is the correct size for your application.

Calculation of estimated amount of working refrigerant:

The amount of working refrigerant can be estimated by the following formula:

Tons of cooling capacity x 4.5 LBS/Ton + Full Liquid Line Charge between Evaporator and Condenisng

Unit

For example, a system of 12,000 BTUH @ -20F suction, 50 ft 1/2” liquid line run, R404A, 100F Liquid,

the working amount of refrigerant is: 1 x 4.5 + 6.5 x 50/100 = 7.75 LBS R404A. The actual charge should be

approximately this working amount of refrigerant.

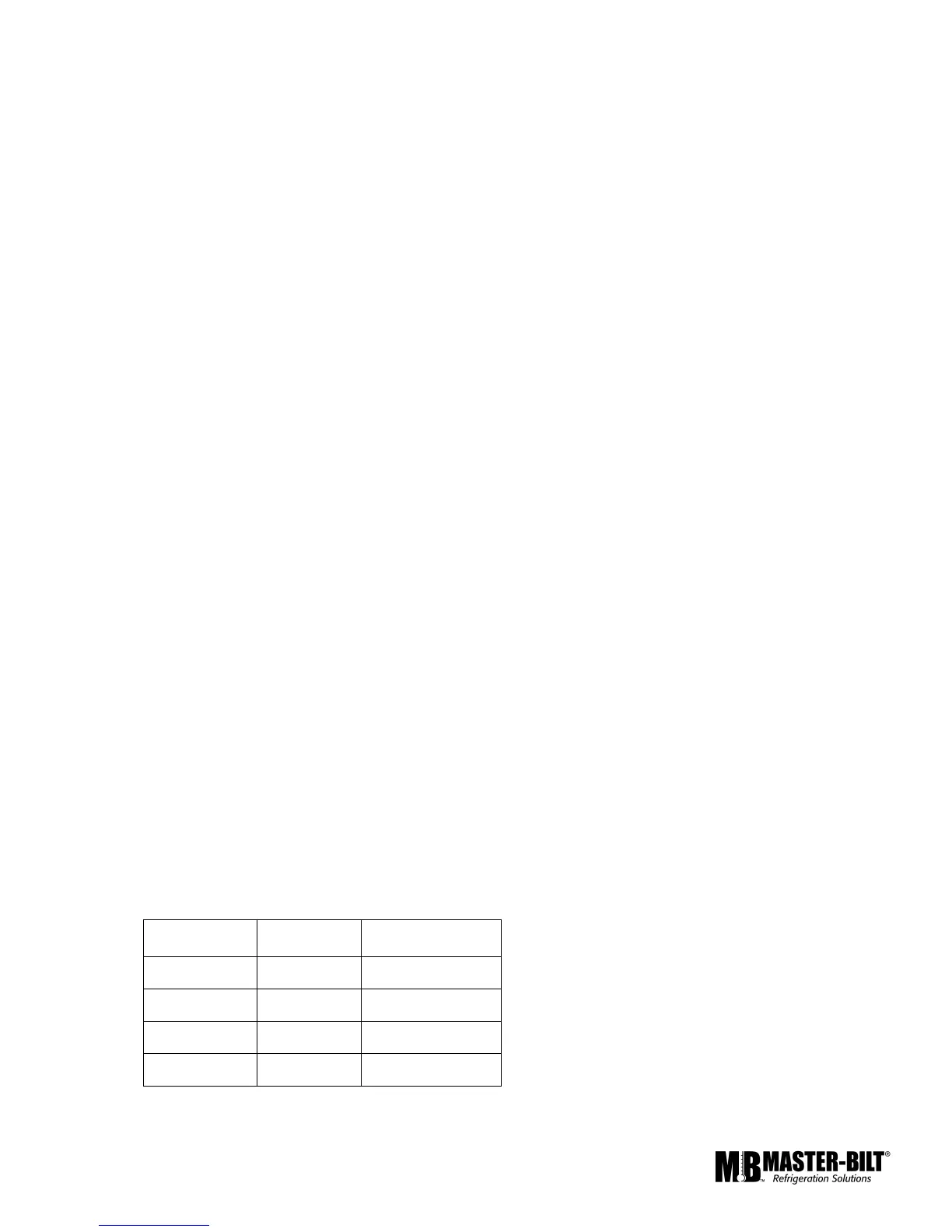

Weight of Refrigerant in LBS per 100 ft of Liquid Line:

The recommended charging procedures are:

Liquid Line

Size, Inch

Refrigerant Lbs of Refrigerant

3/8 R22

R404A

4.0

3.5

1 /2 R22

R404A

7.5

6.5

5/8 R22

R404A

12.0

10.5

7/8 R22

R404A

24.5

21.0

Loading...

Loading...