8

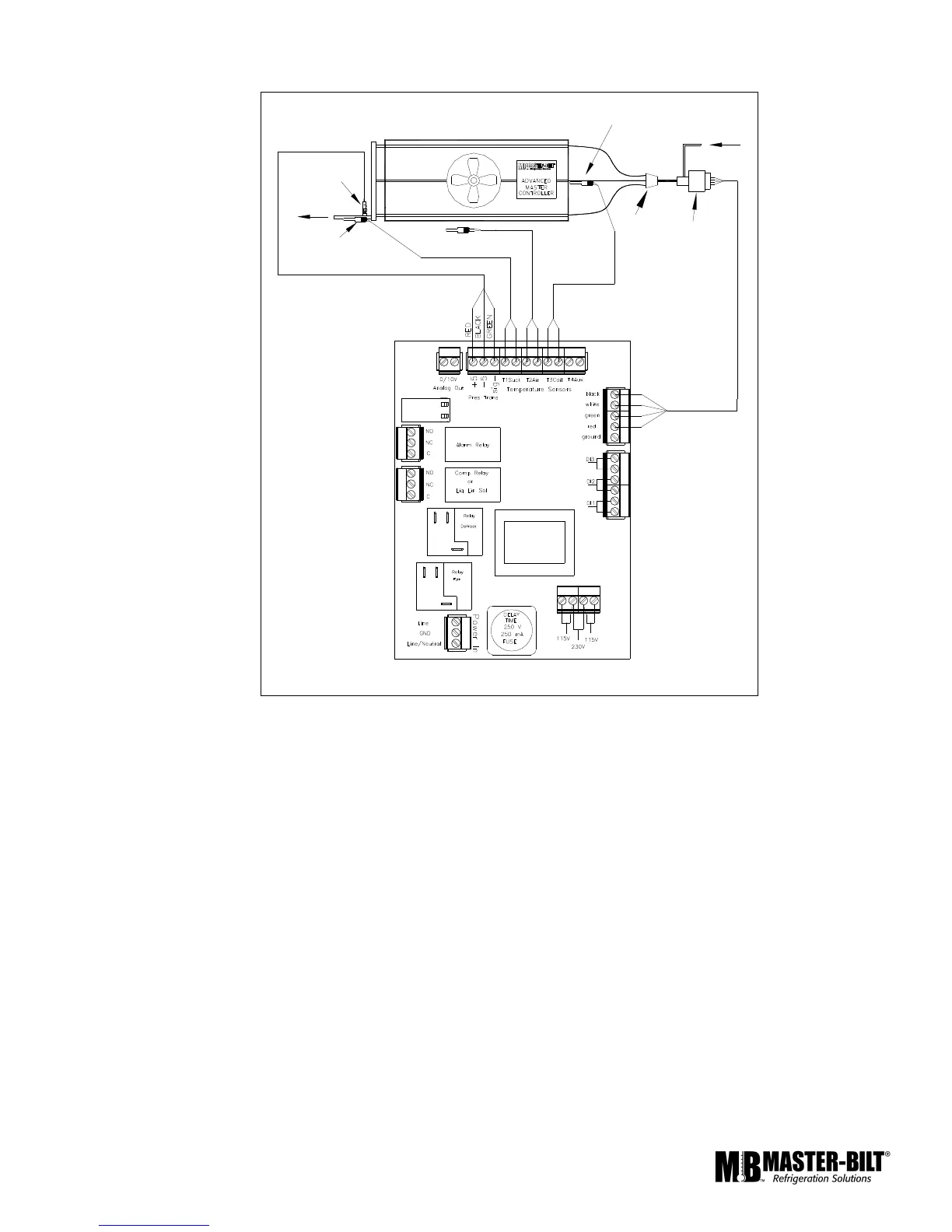

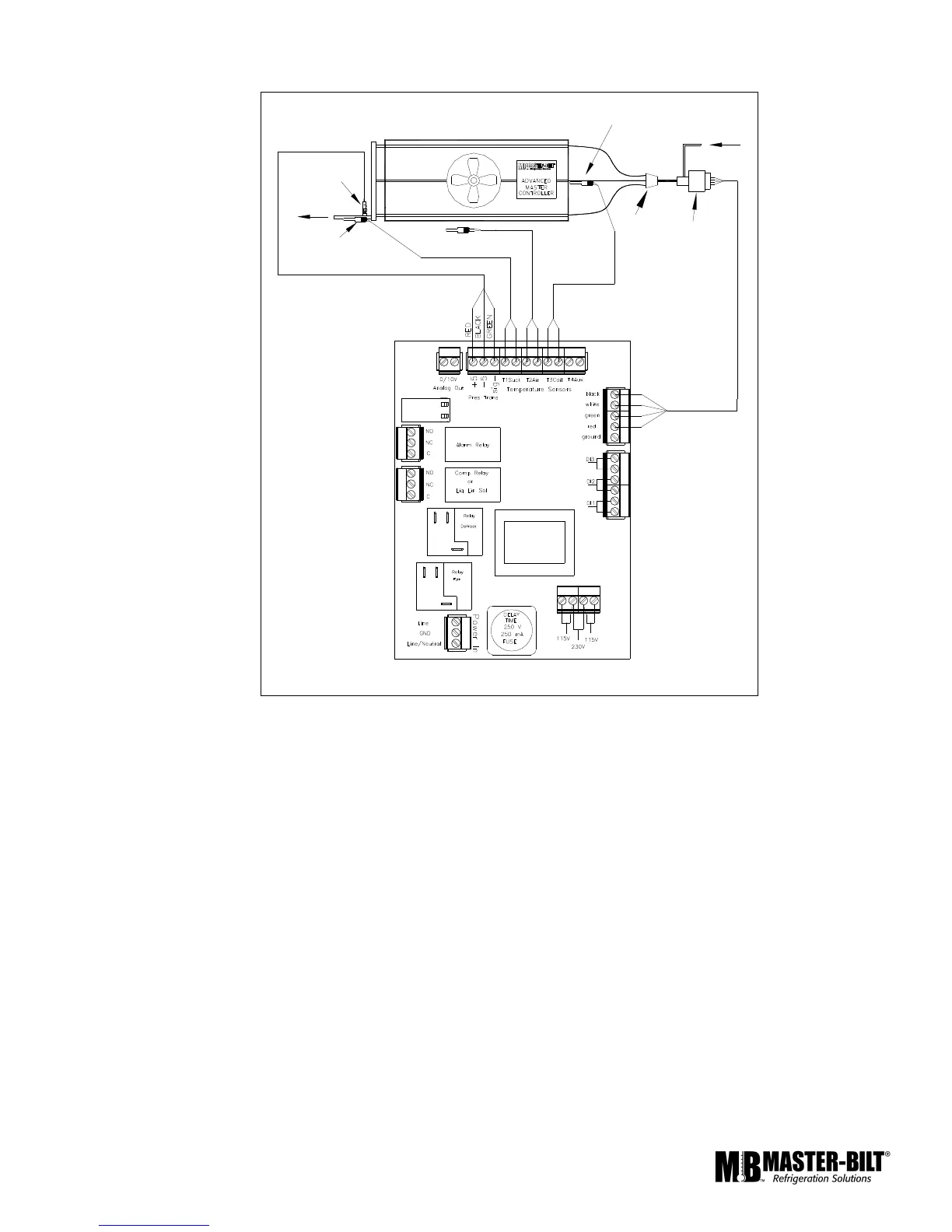

Pressure

T1 T2

T3

Transducer

Valve

Electric

Liquid Line

Evaporator

Defrost Temp. Sensor

Evap Coil In/

Distributor

Room Temp Sensor

Temp Sensor

Evap out / Fan Delay

Suction Line

ADVANCED MASTER CONTROLLER

Expansion

Figure 2.

Factory-Mounted Parts

• A controller board, an electric expansion valve, a pressure transducer, and three temperature sensors

for single evaporator system (standalone or alternating) or peer (multiple evaporator system)

evaporator are pre-mounted at the factory. . For a multiple evaporator system, only 1 evaporator is

required to have an air temperatue sensor. For reverse cycle defrost, a 24 VAC 40VA transformer is

mounted at standalone or master evaporator to provide power 24VAC to the four-way reversing valve

mounted in the condensing unit. The control circuit and power supply are pre-wired to the terminal

board of the evaporator. The board is molded in epoxy to avoid excessive moisture in cold room.

• A 4-way reversing valve, operating at 24 VAC, is installed in a reverse cycle defrost equipped unit. A

transformer is also installed in one of the evaporators to supply 24VAC to the 4-way reversing valve.

• Peer to Peer controls can be connected directly to each other, using a CAT-5E cable, if there are only

2 controllers. The controllers must be connected through an Ethernet switch or router if 3 or more

controllers are on the system. The controllers must be bonded together. A technician should install the

CAT-5E cable from the controllers to the Ethernet switch or router and bond the controllers. All

components are factory tested. A technician should check all the wiring and settings for proper

operation after installation.

Loading...

Loading...